Method capable of reducing grade of gold in crude antimony leaching solution

A technology of leaching solution and gold grade, which is applied in the direction of process efficiency improvement, photographic process, instruments, etc., can solve the problems of low antimony quality and difficult gold recovery, etc., and achieve the effect of reduced gold content, low operating cost, and simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

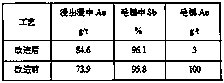

[0018] The main components of the antimony-containing raw ore and the antimony-gold concentrate obtained after flotation are shown in Table 1:

[0019] Table 1 Composition analysis of antimony-containing ore and antimony-gold concentrate

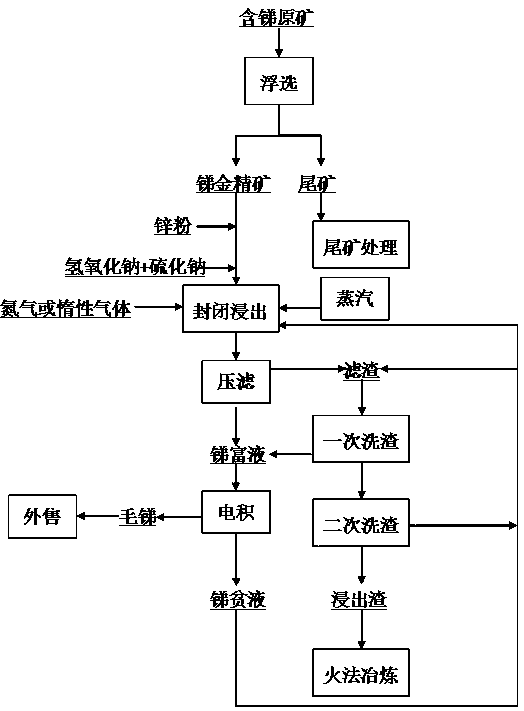

[0020] Take the following process steps:

[0021] a Mineral dressing: The flotation conditions and dosage of antimony raw ore are raw ore particle size-200 mesh ratio ≥ 80%, isoamyl xanthate 50 g / t, ethyl xanthate 150 g / t, lead nitrate 150 g / t t, 2# oil 50 g / t; flotation to produce antimony gold concentrate;

[0022] b Leaching: add zinc powder at a rate of 1 kg per ton of antimony-gold concentrate (dry basis), and use high-concentration sodium hydroxide and low-concentration sodium sulfide for leaching in a sealed reaction kettle filled with nitrogen; sodium hydroxide The concentration is 200 g / L, the concentration of sodium sulfide is 30 g / L, the liquid-solid ratio is 1:1, and the leaching temperature is 60 ℃. After stirring and leachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com