Copper-based MOF carbonization derived catalytic material and preparation method and application thereof

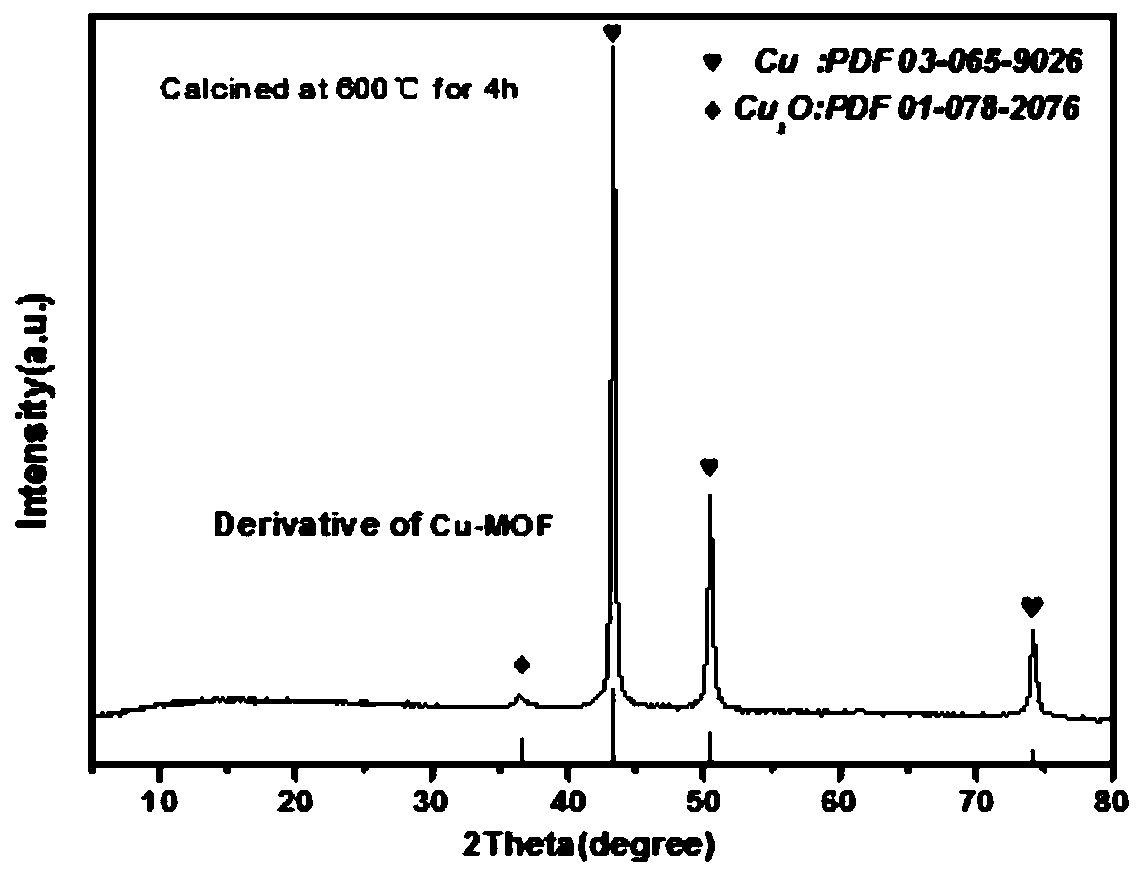

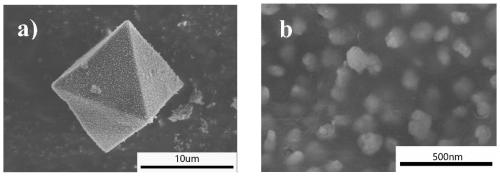

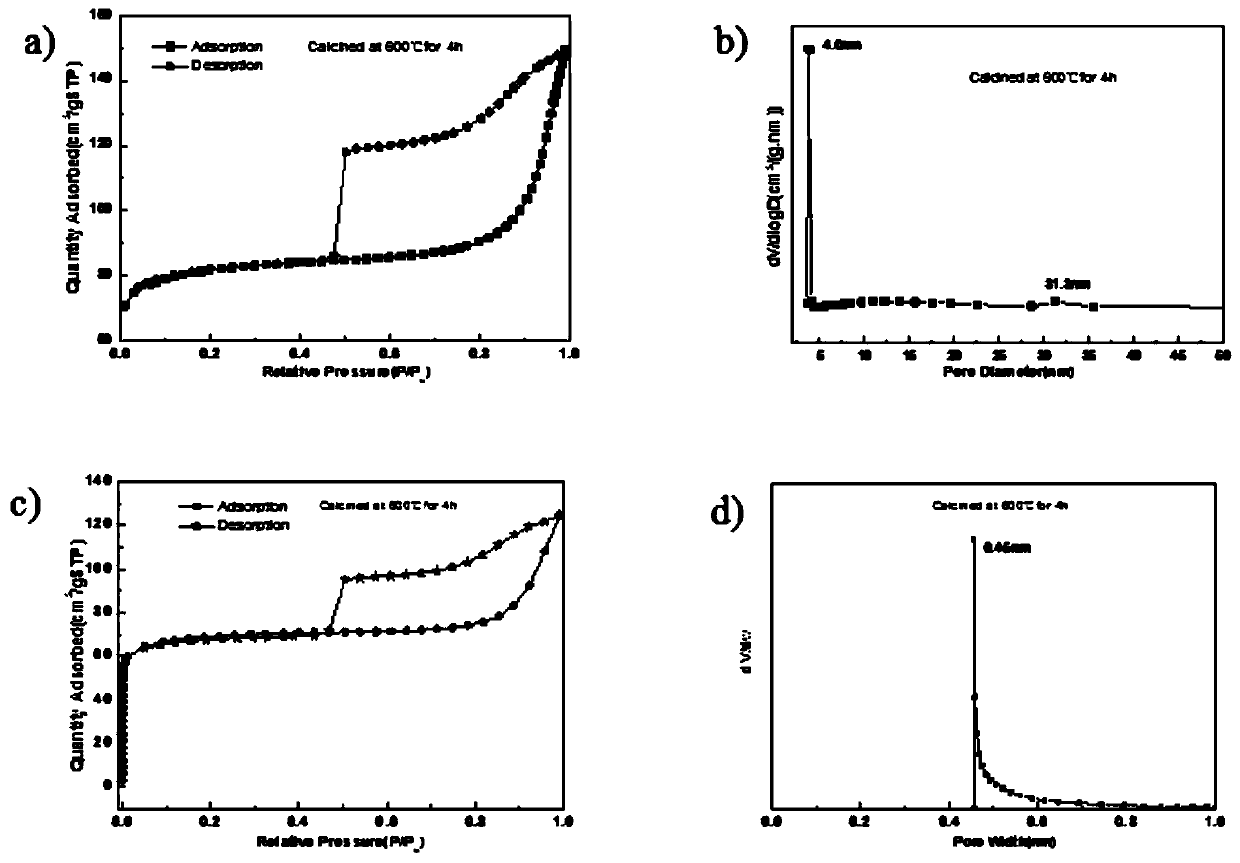

A catalytic material, copper-based technology, applied in the field of copper-based MOF carbonization-derived catalytic materials and its preparation, can solve the problems of limited precious metal resources, high price, metal particle agglomeration, etc., achieve excellent catalytic activity and selectivity, and simple preparation method , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A copper-based MOF carbonization derivative catalytic material, its preparation method comprises the following steps:

[0046] 1) Weigh 3.5g (14.48mmol) Cu(NO 3 ) 2 ·3H 2O is placed in a 150mL beaker, and 48mL of deionized water is added, and stirred at 500r / min for 5min to obtain a copper ion precursor; weigh 1.68g (8mmol) H 3 BTC was placed in a 150mL beaker, added to 48mL of absolute ethanol, and stirred at 500r / min for 10min to obtain an organic ligand precursor;

[0047] 2) Add the copper ion precursor solution obtained in step 1) dropwise into the organic ligand precursor solution, and stir at 600r / min for 20min to obtain the mixed solution I;

[0048] 3) Pour the mixed solution I obtained in step 2) into a 150mL polytetrafluoroethylene liner, put it into a reaction vessel, and then place it in a 120°C oven for hydrothermal reaction for 18 hours to obtain the turbid solution II; then carry out suction filtration, and use 500mL Wash with deionized water for 5 t...

Embodiment 2

[0056] A copper-based MOF carbonization derivative catalytic material, its preparation method comprises the following steps:

[0057] 1) Weigh 3.5g (14.48mmol) Cu(NO 3 ) 2 ·3H 2 O is placed in a 150mL beaker, and 48mL of deionized water is added, and stirred at 500r / min for 5min to obtain a copper ion precursor; weigh 1.68g (8mmol) H 3 Place BTC in a 150mL beaker, add 48mL of absolute ethanol, and stir at 500r / min for 5min to obtain an organic ligand precursor;

[0058] 2) Add the copper ion precursor solution obtained in step 1) dropwise into the organic ligand precursor solution, and stir at 600r / min for 20min to obtain the mixed solution I;

[0059] 3) Pour the mixed solution I obtained in step 2) into a 150mL polytetrafluoroethylene liner, put it into a reaction vessel, and then place it in a 120°C oven for hydrothermal reaction for 18 hours to obtain the turbid solution II; then carry out suction filtration, and use 500mL The mixed solution of deionized water and abso...

Embodiment 3

[0068] A copper-based MOF carbonization derivative catalytic material, its preparation method comprises the following steps:

[0069] 1) Weigh 2.9g (12mmol) Cu(NO 3 ) 2 ·3H 2 O is placed in a 150mL beaker, and 48mL of deionized water is added, and stirred at 500r / min for 5min to obtain a copper ion precursor; weigh 1.68g (8mmol) H 3 Place BTC in a 150mL beaker, add 48mL of absolute ethanol, and stir at 500r / min for 5min to obtain an organic ligand precursor;

[0070] 2) Add the copper ion precursor solution obtained in step 1) dropwise into the organic ligand precursor solution, and stir at 600r / min for 20min to obtain the mixed solution I;

[0071] 3) Pour the mixed solution I obtained in step 2) into a 150mL polytetrafluoroethylene liner, put it into a reaction vessel, and then place it in a 120°C oven for hydrothermal reaction for 18 hours to obtain the turbid solution II; then carry out suction filtration, and use 500mL The mixed solution of deionized water and absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com