High temperature resistant alumina ceramic fiber and its sol-gel preparation method

A high-temperature-resistant technology for alumina ceramics, applied in the field of ceramic fiber and its preparation, and sol-gel preparation of high-temperature-resistant alumina ceramic fiber, can solve the problem of high threshold for continuous filament preparation, limited application, and the use of alumina ceramic fiber temperature limitations etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

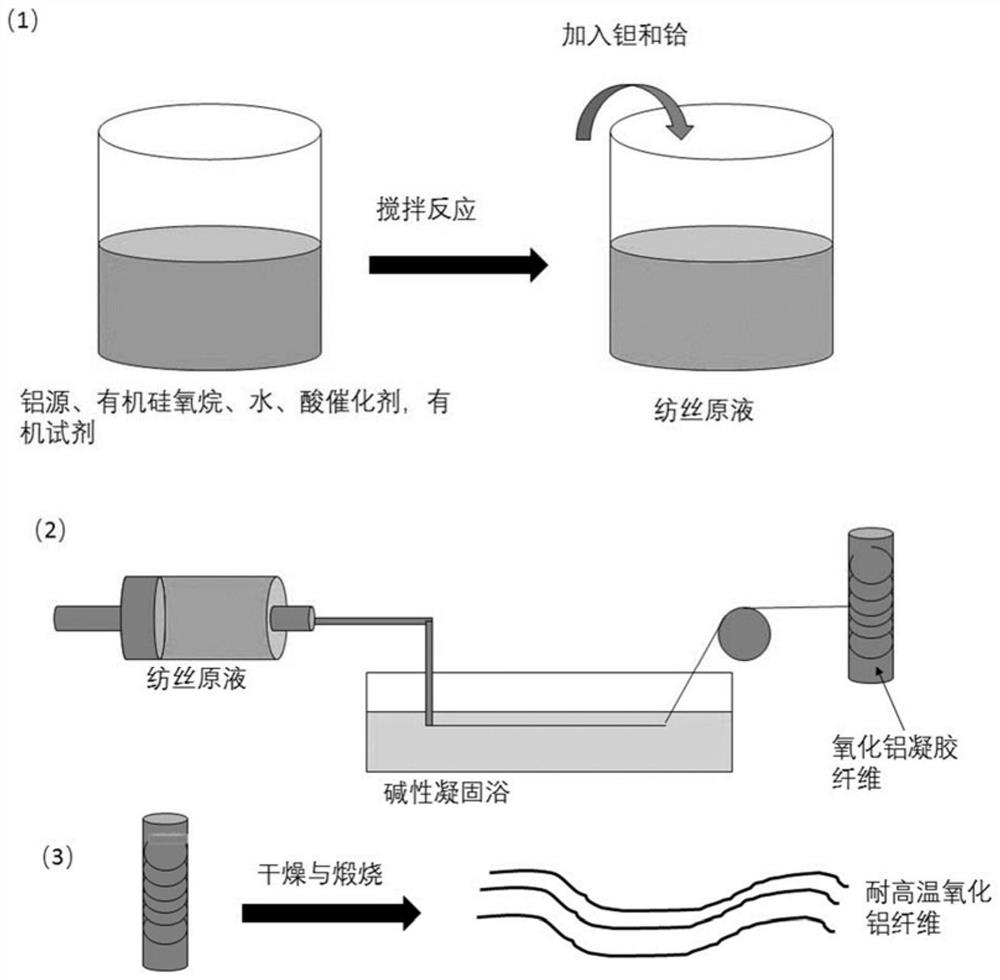

[0025] According to the first aspect of the present disclosure, a method for preparing high temperature resistant alumina ceramic fiber includes three key steps: (1) preparation of aluminum source spinning dope; (2) configuration of coagulation bath and sol-gel spinning ; (3) Drying and calcination of fiber. Specifically, such as figure 1 As shown, the preparation method includes: fully dissolving the aluminum source, organosiloxane, water, and acid catalyst in an organic solvent, reacting at a certain temperature for a certain period of time, then adding a tantalum source and a hafnium source, and stirring uniformly to prepare the spinning Silk dope; prepare an alkaline coagulation bath; spin the dope through the alkaline coagulation bath to form alumina gel fiber through sol-gel chemical conversion; and the alumina gel fiber is dried at room temperature and then calcined, Obtain high temperature resistant alumina ceramic fiber.

[0026] According to another embodiment of the p...

Embodiment 1

[0042] Disperse 80g of aluminum powder and 50g of aluminum isopropoxide in 200g of ethanol, and then add 5g of ethyl orthosilicate dropwise to it. After stirring, add 0.4g of deionized water and 0.2g of 36% hydrochloric acid. Stir and react at 80°C for 24 hours. Add 0.13g of tantalum powder and 5g of a mixture of hafnium dioxide and hafnium hydroxide to the above solution, and stir evenly to obtain spinning dope; take 1L of ethanol, add 0.08g of sodium hydroxide, and stir for 5 Obtain a coagulation bath within hours; control the temperature of the coagulation bath at 10°C, and then spin the prepared spinning dope into the coagulation bath and collect it with a roller to obtain alumina ceramic gel fibers; put the above alumina ceramic gel fibers at room temperature Drying for 5 hours, then calcining at 800°C for 30 minutes, 1000°C for 30 minutes, and finally at 1300°C for 10 minutes to obtain alumina ceramic fibers.

Embodiment 2

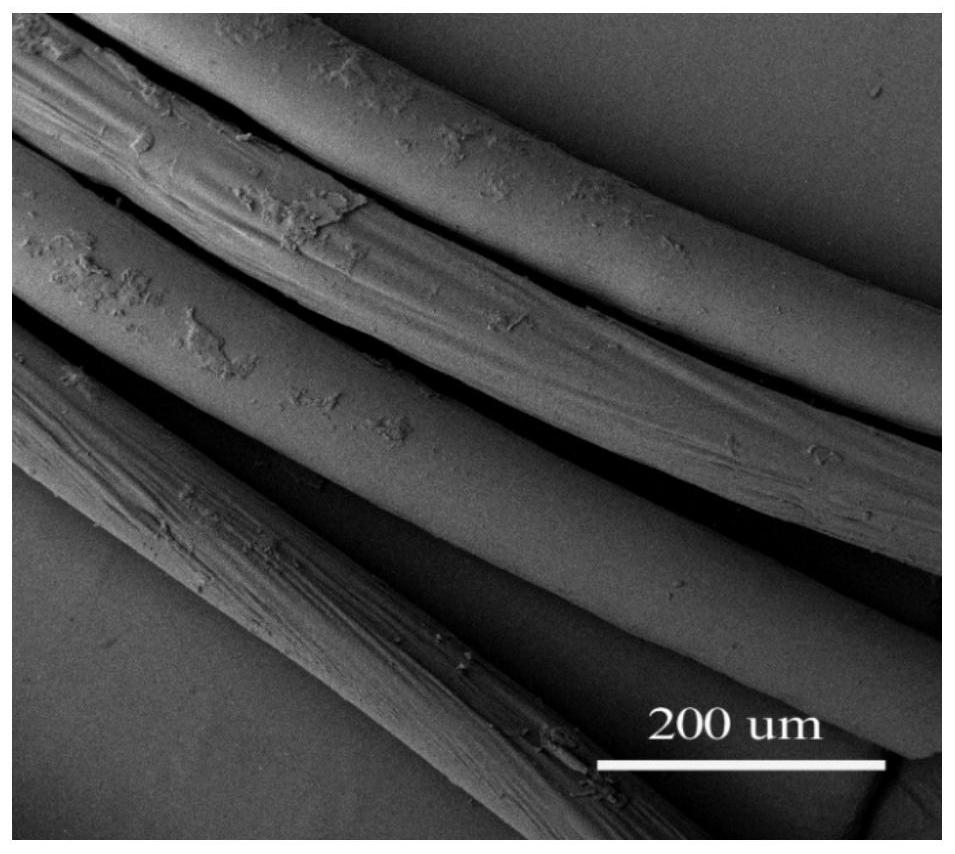

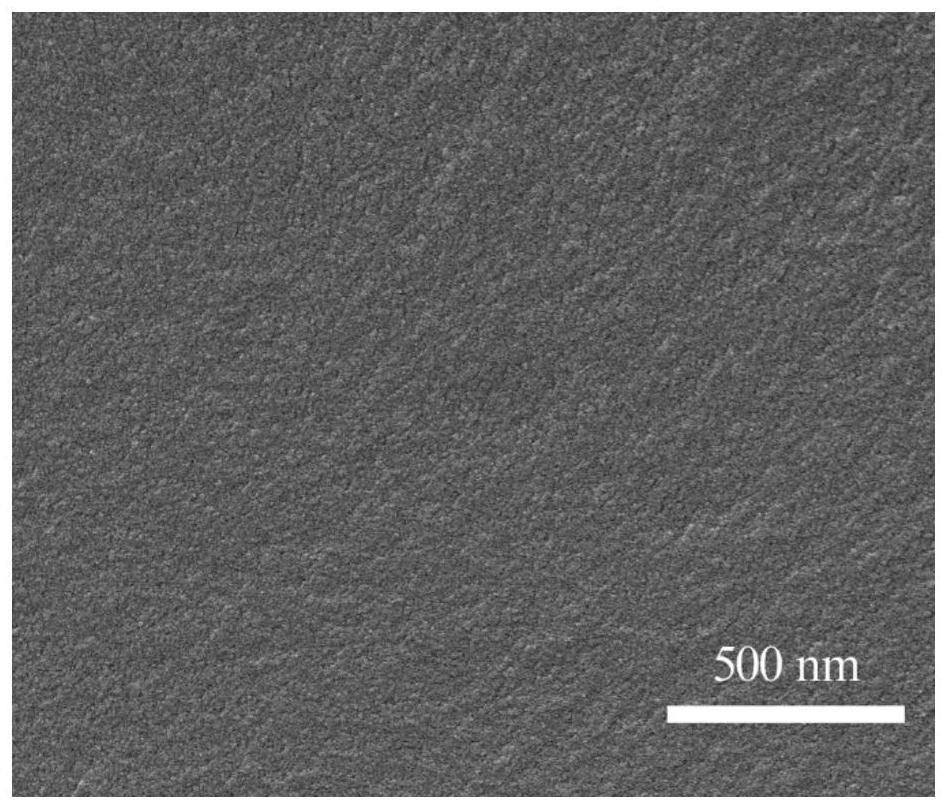

[0044] Disperse 80g of aluminum powder and 20g of aluminum chloride in 100g of methanol, and then add 1g of methyl orthosilicate dropwise to it. After stirring evenly, add 0.12g of deionized water and 0.06g of 36% hydrochloric acid. Stir and react at ℃ for 20 hours. Add 1g lithium tantalate and 2.5g hydrated hafnium oxychloride to the above solution, and stir evenly to prepare spinning dope; take 1L methanol, add 0.05g sodium hydroxide and stir for 2 hours to obtain solidification Bath; control the temperature of the coagulation bath at 50°C, and then spin the prepared spinning dope into the coagulation bath and collect it with a roller to obtain alumina ceramic gel fiber; dry the alumina ceramic gel fiber at room temperature for 24 hours Then calcined at 800°C for 10 minutes, 1000°C for 30 minutes, and finally at 1200°C for 20 minutes to obtain alumina ceramic fibers. The scanning electron microscope image of the alumina ceramic fiber prepared in this embodiment is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com