A kind of preparation method of rubber composition containing highly dispersed carbon nanotubes

A rubber composition and carbon nanotube technology, which can be used in transportation and packaging, rolling resistance optimization, special tires, etc., can solve the problems of easy agglomeration, poor adhesion between carbon nanotubes and solution-polymerized styrene-butadiene rubber matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

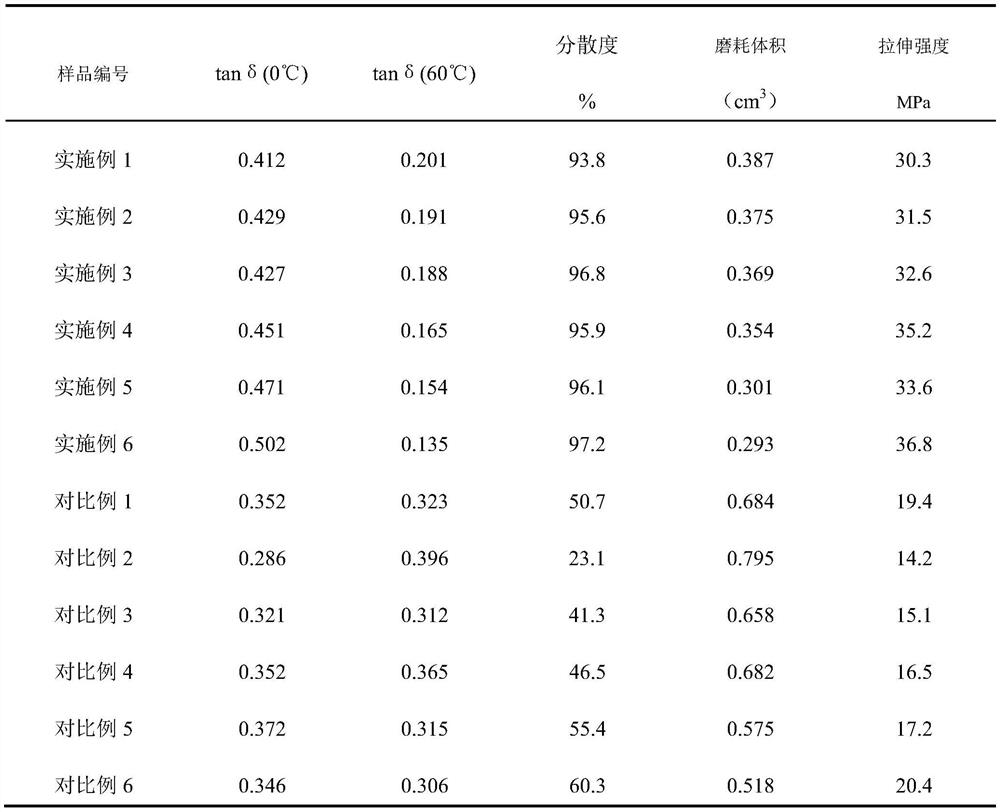

Examples

Embodiment 1

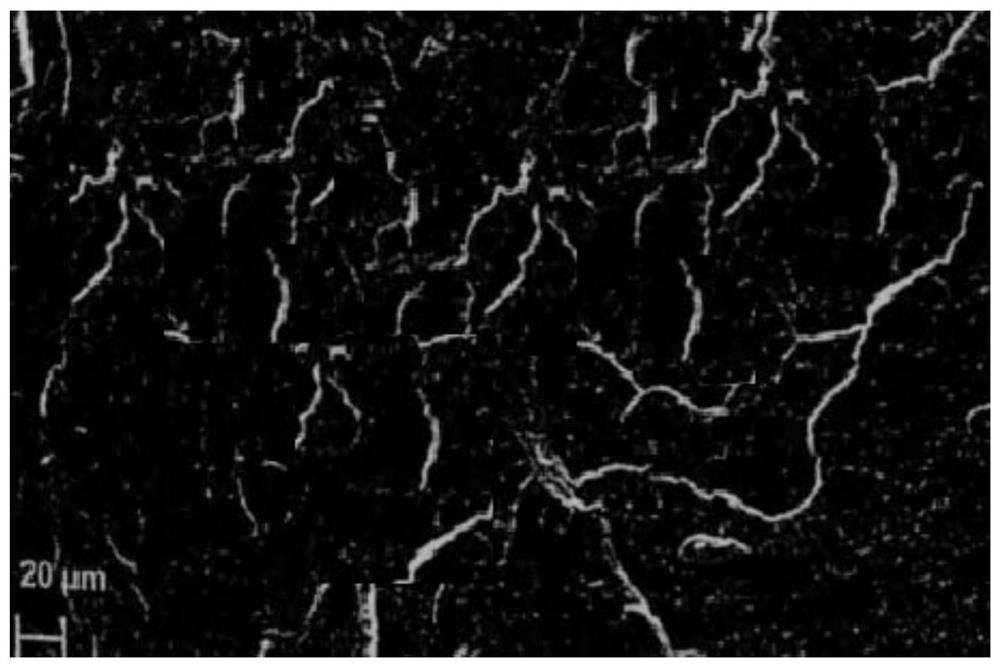

[0045] (1) Preparation of highly dispersed carbon nanotubes:

[0046] a The preparation of amination of carbon nanotubes: 100 parts of carbon nanotubes, 150 parts of concentrated nitric acid, 50 parts of concentrated sulfuric acid, and 10 parts of potassium permanganate are mixed in a reactor, treated with 50 kHz ultrasonic waves for 1 hr, and then heated to At 50°C, stir and cook with acid for 2 hours, cool, filter, and wash until the filtrate is neutral, then add 200 parts of hexamethylenetetramine, then heat to 70°C, stir and react for 2 hours, filter with suction, wash, and dry. The carbon nanotube a with amine groups on the surface is obtained.

[0047] b Preparation of grafted solution-polymerized styrene-butadiene mortar: first add 300 parts of cyclohexane to the polymerization kettle, then add 100 parts of solution-polymerized styrene-butadiene mortar SSBR2564s, 0.05 parts of tert-dodecyl mercaptan in turn, and replace with nitrogen , add 1 part of methacrylamide, sti...

Embodiment 2

[0051] (1) Preparation of highly dispersed carbon nanotubes:

[0052] a The preparation of amination of carbon nanotubes: the same as in Example 1.

[0053] Preparation of b grafted solution-polymerized styrene-butadiene mortar: same as Example 1.

[0054] c Preparation of highly dispersed carbon nanotubes: Take 100 parts of aminated carbon nanotubes a and 350 parts of cyclohexane and add them to the polymerization kettle and stir and mix for 15 minutes; The temperature was raised to 60° C., and after stirring and reacting for 3 hours, high-dispersion carbon nanotubes were obtained through flash evaporation, drying and grinding.

[0055] (2) Preparation of solution-polymerized styrene-butadiene rubber composition for tread: Take 100 parts of solution-polymerized styrene-butadiene rubber SSBR2564s (dry rubber) and 60 parts of cyclohexane into the coagulation kettle and stir and mix for 10 minutes, then add 20 parts of high For dispersed carbon nanotubes, when the temperature ...

Embodiment 3

[0057] (1) Preparation of highly dispersed carbon nanotubes:

[0058] a The preparation of amination of carbon nanotubes: put 100 parts of carbon nanotubes, 180 parts of concentrated nitric acid, 70 parts of concentrated sulfuric acid, and 30 parts of potassium permanganate into the reactor and mix them together, treat them with 80kHz ultrasonic wave for 1.5hr, and then heat Stir and cook for 5 hours at 70°C, cool, filter, and wash until the filtrate is neutral, then add 300 parts of hexamethylenetetramine, then heat to 80°C, stir for 3 hours, filter with suction, wash, and dry , to obtain carbon nanotubes b with amine groups on the surface.

[0059] b Preparation of grafted solution-polymerized styrene-butadiene mortar: first add 450 parts of cyclohexane to the polymerization kettle, then add 100 parts of solution-polymerized styrene-butadiene mortar SSBR2564s, 0.3 parts of tert-dodecyl mercaptan in sequence, and replace with nitrogen , add 7 parts of methacrylamide, stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com