Orchard anti-insect glue, and preparation method thereof

A technology for preventing shellac and orchards, applied in the directions of adhesives, adhesive types, adhesive additives, etc., can solve the problems of narrow use temperature range, easy aging, high use cost, etc., to achieve wide use temperature range and long-lasting bonding effect. , The effect of good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

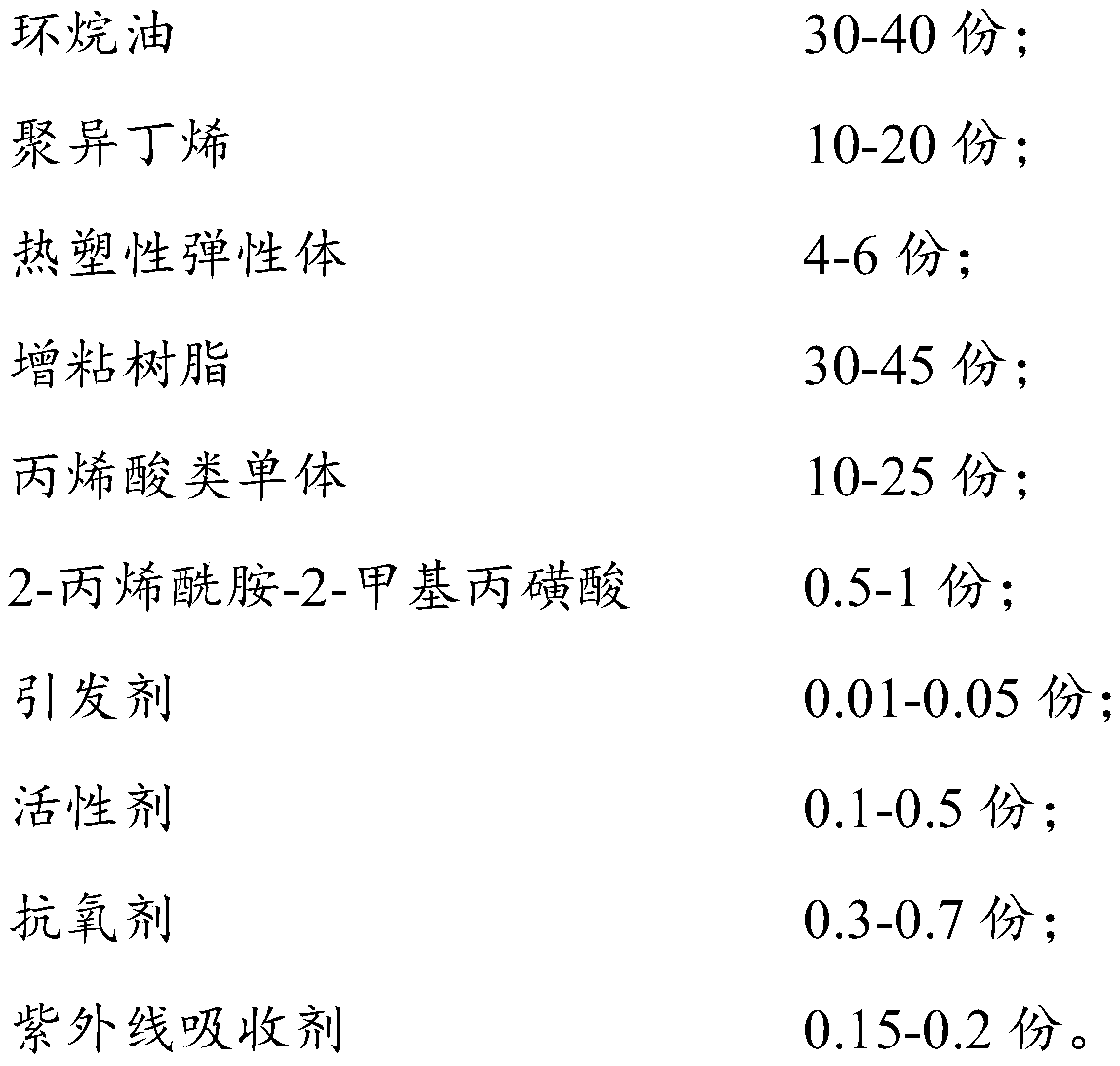

[0028] Orchard anti-shellac, comprising the following raw materials by weight percentage:

[0029] 30 parts of naphthenic oil; 10 parts of polyisobutylene; 4 parts of thermoplastic elastomer; 30 parts of tackifying resin; 10 parts of acrylic monomer (methyl methacrylate: butyl acrylate = 1:5); 0.5 part of 2-methylpropanesulfonic acid; 0.01 part of initiator (ammonium persulfate); 0.1 part of active agent (zinc stearate); 0.3 part of antioxidant (1010); ultraviolet absorber (benzotriazoles) 0.15 servings.

[0030] Put the active agent, 30% acrylic monomer and 30% initiator into the reaction kettle, stir and react at 60°C for 1 hour; add 2-acrylamide-2-methylpropanesulfonic acid and the remaining acrylic monomer Add it into the reaction kettle, and raise the temperature to 70°C, continue to stir and react for 3h; add the remaining initiator into the reaction kettle, and after continuing to react for 2h, add 40% naphthenic oil, antioxidant, ultraviolet absorbing and heat up to ...

Embodiment 2

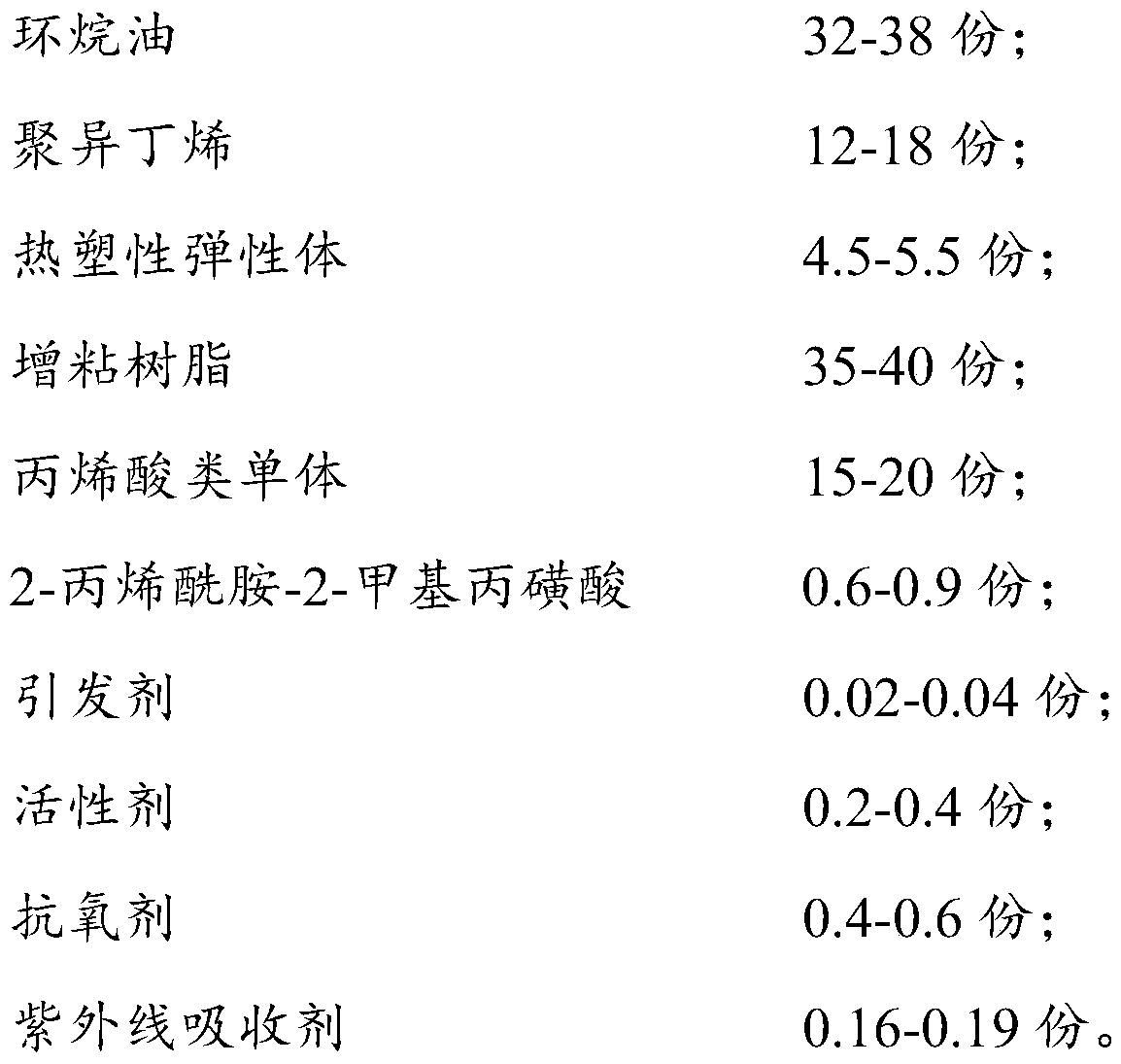

[0032] Orchard anti-shellac, comprising the following raw materials by weight percentage:

[0033] 40 parts of naphthenic oil; 20 parts of polyisobutylene; 6 parts of thermoplastic elastomer; 45 parts of tackifying resin; 25 parts of acrylic monomer (methyl methacrylate: isooctyl acrylate = 1:6); 2-acrylamide -1 part of 2-methylpropanesulfonic acid; 0.05 part of initiator (ammonium persulfate); 0.5 part of active agent (OP-10); 0.7 part of antioxidant (168); 0.2 part of ultraviolet absorber (triazine) .

[0034] Put the active agent, 30% acrylic monomer and 30% initiator into the reaction kettle, stir and react at 70°C for 2 hours; add 2-acrylamide-2-methylpropanesulfonic acid and the remaining acrylic monomer Add it into the reaction kettle, and raise the temperature to 90°C, continue to stir and react for 4h; add the remaining initiator to the reaction kettle, and after continuing to react for 3h, add 40% naphthenic oil, antioxidant, ultraviolet absorbing and heat up to 10...

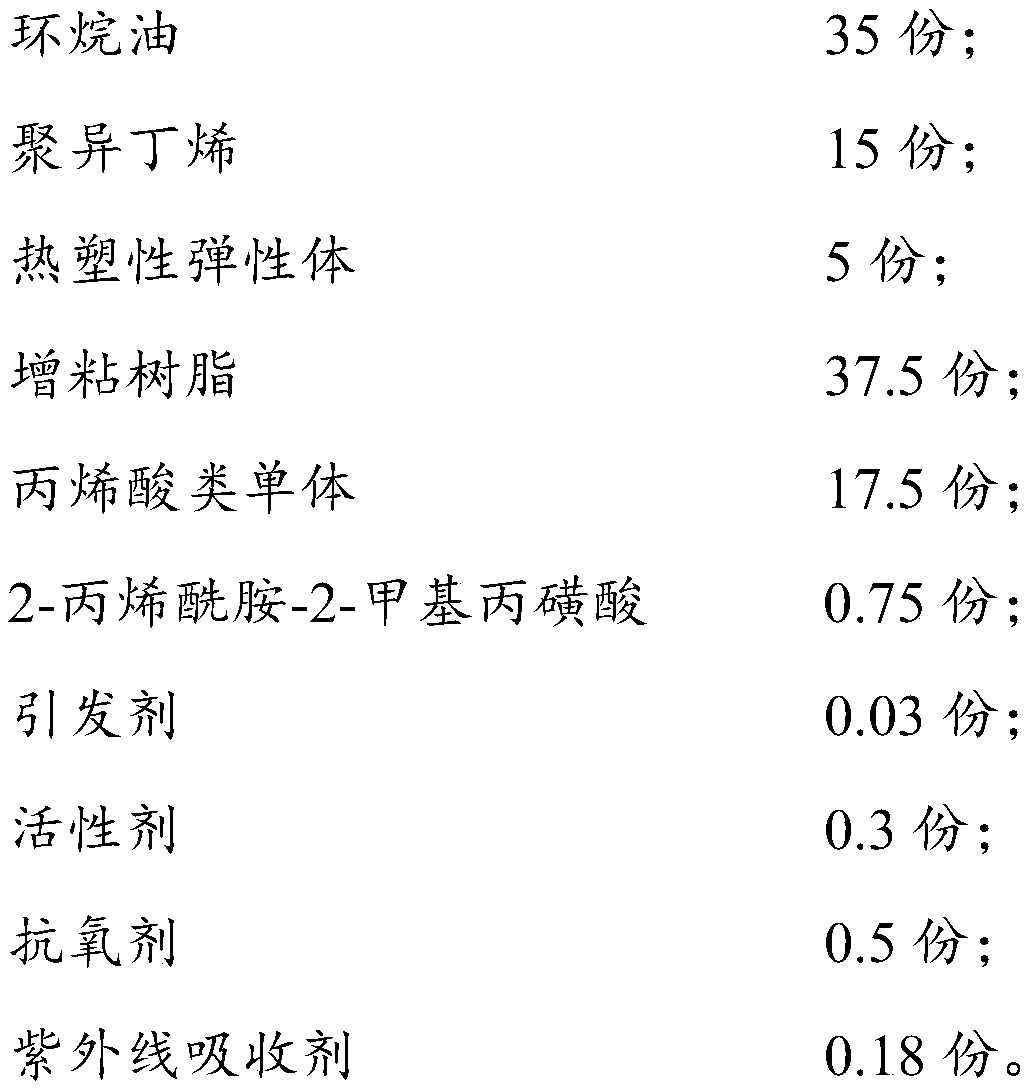

Embodiment 3

[0036] 32 parts of naphthenic oil; 12 parts of polyisobutylene; 4.5 parts of thermoplastic elastomer; 35 parts of tackifying resin; 15 parts of acrylic monomer (butyl acrylate: isooctyl acrylate = 1:7); 2-acrylamide-2 - 0.6 part of methylpropanesulfonic acid; 0.02 part of initiator (sodium persulfate); 0.2 part of active agent (K12); 0.4 part of antioxidant (1076); 0.16 part of ultraviolet absorber (hindered amines).

[0037] Put the active agent, 30% acrylic monomer and 30% initiator into the reaction kettle, stir and react at 65°C for 1.5h; add 2-acrylamide-2-methylpropanesulfonic acid and the remaining acrylic monomer Add the solid to the reaction kettle, and raise the temperature to 75°C, continue to stir and react for 3-4h; add the remaining initiator to the reaction kettle, continue to react for 2.5h, add 40% naphthenic oil, antioxidant agent, ultraviolet absorber, and heat up to 95°C; add thermoplastic elastomer into the reaction kettle, stir for 2 hours, continue to ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com