Catalytic high-pressure decomposition reactor for treating industrial waste gas

A technology for decomposing reactors and industrial waste gas, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of complex technology, difficult treatment effect to meet emission requirements, high operation and maintenance costs, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

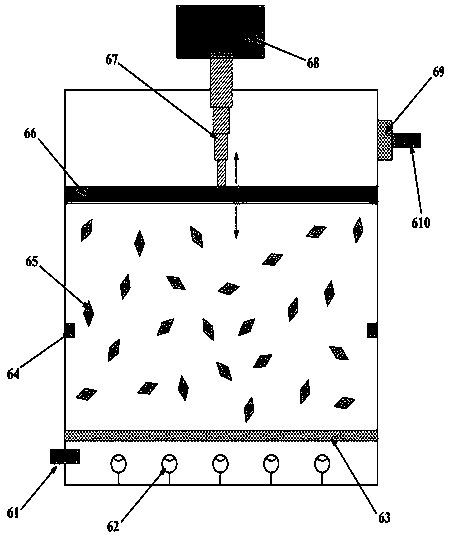

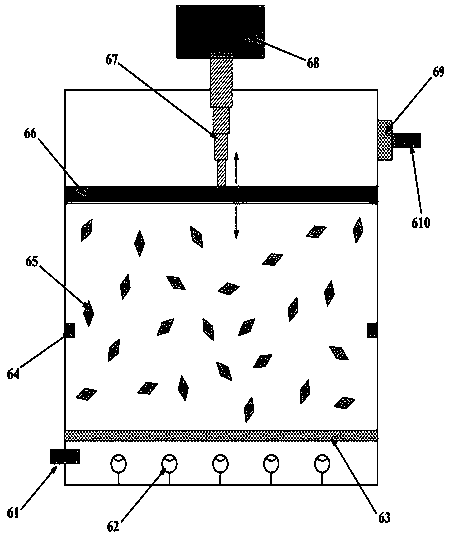

[0030] like figure 1 As shown, a catalytic high-pressure decomposition reactor for treating industrial waste gas is made of stainless steel, with an inlet valve 61 on the lower left side, an ultra-fine filter 69 and an exhaust valve 610 on the upper right side, and the bottom of the reactors are arranged side by side Five ultraviolet generators 62 are installed, a foil protective net 63 is arranged above the ultraviolet generator 62, and a piston stopper 64 is respectively installed on the left and right sides above the foil protective net 63, and the inside of the reactor is uniform A number of nickel-palladium alloy foils 65 are floating, and a set of gas compression piston 66 is installed on the top of the reactor, and the gas compression piston 66 is connected to a hydraulic compression device 68 at the top of the reactor by a telescopic transmission rod 67; The waste gas from the petrochemical industry enters the reactor through the intake valve 61 located at the lower le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com