Cathode interface modification material as well as preparation method and application thereof

A technology for modifying materials and cathode interfaces, applied in the field of solar cells, can solve the problems of complex synthesis of interface materials, few reports of non-fullerene solar cell interface materials, poor economy, etc., to optimize the morphology and device efficiency, and improve the photovoltaic Conversion efficiency and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

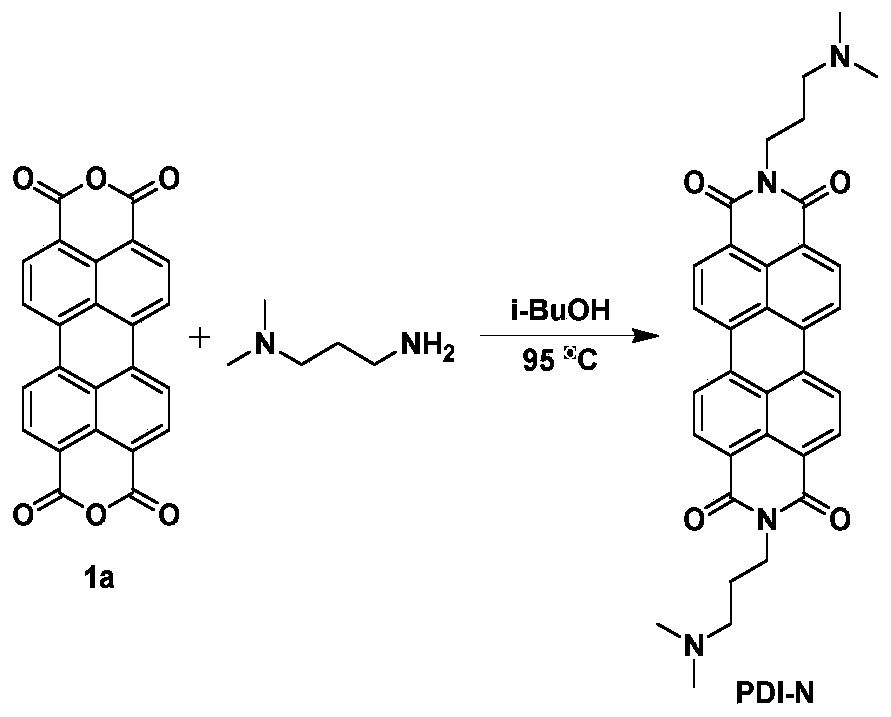

[0063] Such as figure 1 As shown, in this embodiment, the preparation method steps of the cathode interface modification material PDI-N are as follows:

[0064] Under nitrogen atmosphere, compound 1a (2.35g, 6mmol), N,N-dimethyl-1,3-diaminopropane (7.55mL, 60mmol) and 100mL N-methylpyrrolidone were added to a 250mL round bottom flask. Then the temperature was raised to 95°C and refluxed for 24h. After the reaction solution was cooled to room temperature, the crude product was separated by filtration, and the filter cake was washed with 150 mL of water until the filtrate was colorless, and then washed with 150 mL of ethanol until the filtrate was colorless. The obtained residue was heated to 90° C. in 5% aqueous sodium hydroxide solution (150 mL), stirred for 30 min to remove unreacted raw materials. At room temperature, the suspension obtained by reacting with sodium hydroxide was filtered, and the filter cake was washed with 150 mL of water until the filtrate was colorless,...

Embodiment 2

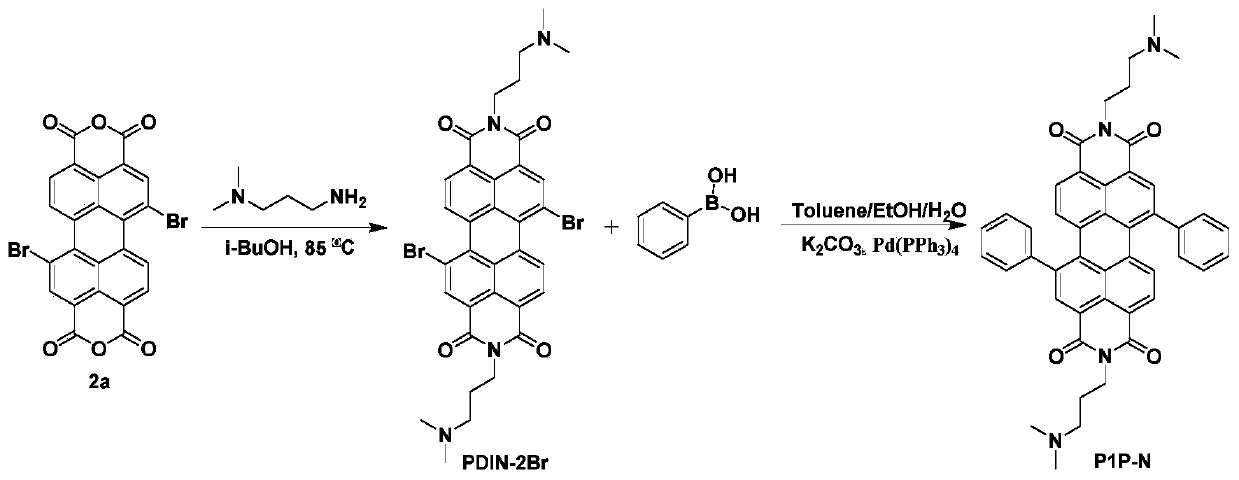

[0068] Such as figure 2 As shown, in this embodiment, the preparation method of the cathode interface modification material P1P-N includes the following steps:

[0069] Step 1. Under nitrogen atmosphere, compound 2a (8.19g, 15mmol), N,N-dimethyl-1,3-diaminopropane (4.16mL, 33mmol) and 260mL isobutanol were added to a 500mL round bottom flask. Then the temperature was raised to 85°C and refluxed for 16h. After the reaction solution was cooled to room temperature, it was poured into water, and a red solid precipitated out. The red solid was isolated by filtration, the filter cake was washed with 150 mL of water until the filtrate was colorless, and then washed with 150 mL of ethanol until the filtrate was colorless. The crude product was purified by silica gel column using dichloromethane:triethylamine (50:1) as eluent to obtain compound PDIN-2Br. It is a red solid with a yield of 61%.

[0070] Characterization of PDIN-2Br by NMR: 1 H NMR (400MHz, CDCl 3 ,δ):9.50-9.48(d,J...

Embodiment 3

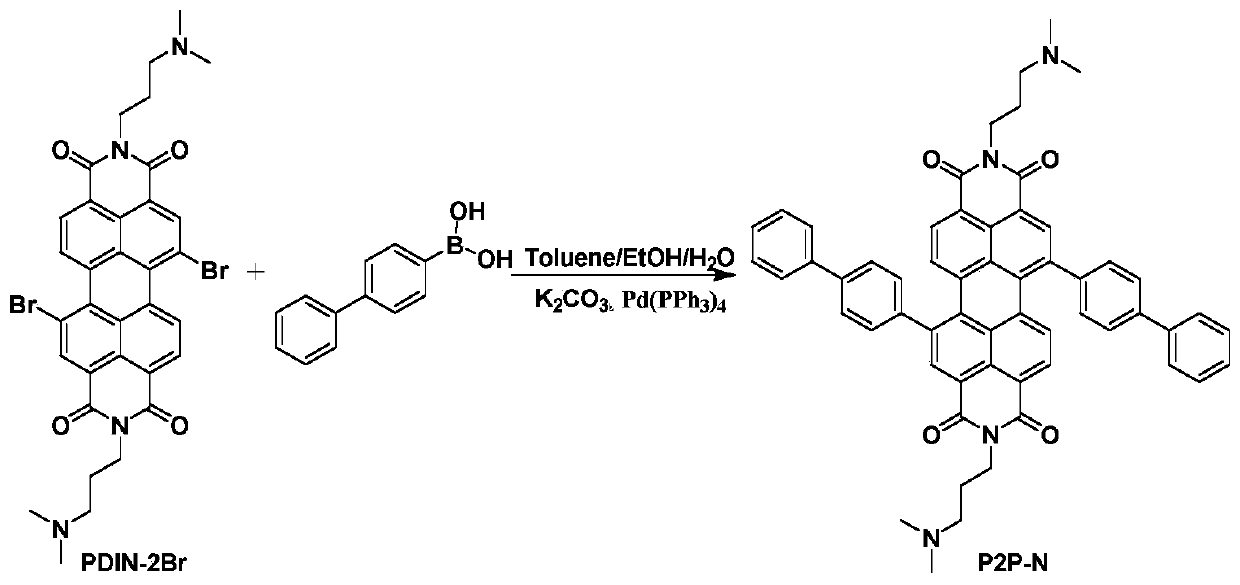

[0076] Such as image 3 As shown, in this embodiment, the preparation method steps of the cathode interface modification material P2P-N are as follows:

[0077] PDIN-2Br (1.99g, 2.80mmol), 4-biphenylboronic acid (1.65g, 8.32mmol), potassium carbonate (3.87g, 28.00mmol) and Pd(PPh 3 ) 4 (catalytic amount) into a Schlenk (250 mL) bottle. Under nitrogen atmosphere, toluene (70 mL), ethanol (42 mL) and water (14 mL) were added respectively. Then the temperature was raised to 100°C and refluxed for 24h. After cooling to room temperature, the reaction solution was concentrated under reduced pressure. Dilute with dichloromethane, add water, extract with dichloromethane, collect the organic phase, dry over anhydrous sodium sulfate, and evaporate under reduced pressure to obtain the crude product. Using dichloromethane: triethylamine (200:1) as the eluent, the compound P2P-N was obtained by purifying on a silica gel column. It is a purple solid with a yield of 78%.

[0078] Char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com