Method for preparing (5-oxo-D-Proline)-leuprolide acetate

A technology of 5-oxo-d-proline and leuprolide acetate, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of high cost and long production cycle, and improve the synthesis yield The effect of minimizing the efficiency, minimizing side reactions, and improving the quality of crude products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

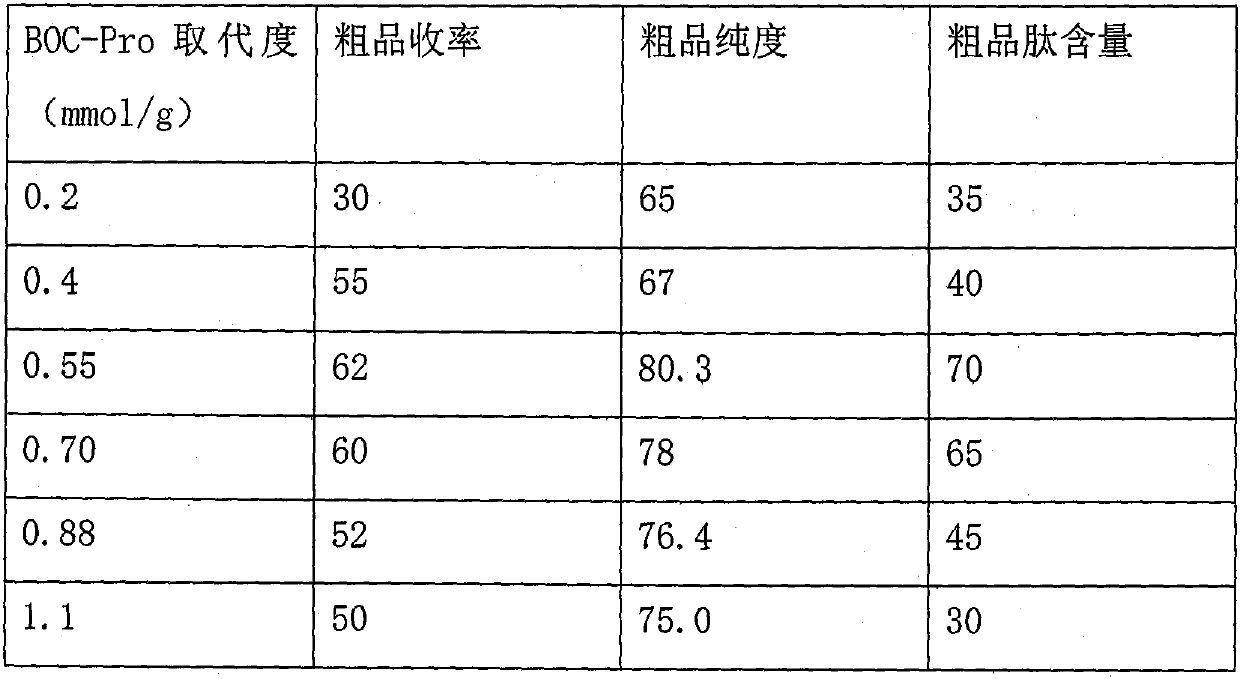

[0078] Example 1 preparation

[0079] 1.1 Preparation of Boc-Pro-Cs: Weigh Boc-Pro, dissolve in methanol, feed 95% excess Cs2CO3, weigh Cs2CO3, dissolve in purified water. Slowly add the Cs2CO3 solution to the Boc-Pro solution, and react fully. At this time, the Boc-Pro-Cs solution should be colorless and transparent, with a pH of 7.0-7.5. In a water bath at 40-50°C, concentrate under reduced pressure with water and evaporate the solvent to obtain solid matter. Add methanol, evaporate to dryness under reduced pressure, and repeat twice, and then vacuum-dry in a P2O5 desiccator to constant weight to obtain a dry product of Boc-Pro-Cs.

[0080] 1.2 Preparation: according to Calculate the amount of chlorine substitution, weigh 2 times the molar amount of the monomer Add DMF to Boc-Pro-Cs, pour it into a three-neck flask after completely dissolving, then wash the eggplant-shaped flask with DMF, and incorporate it into the resin. Stir the reaction in a water bath at 45°C...

Embodiment 2

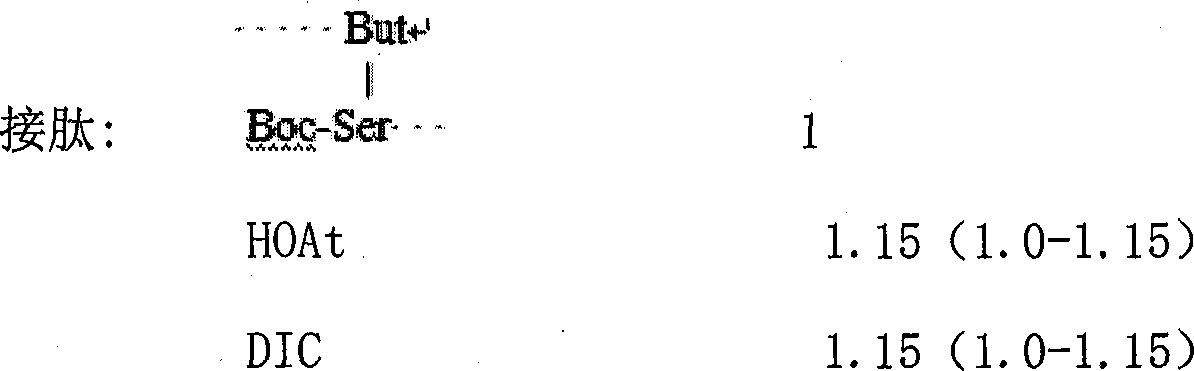

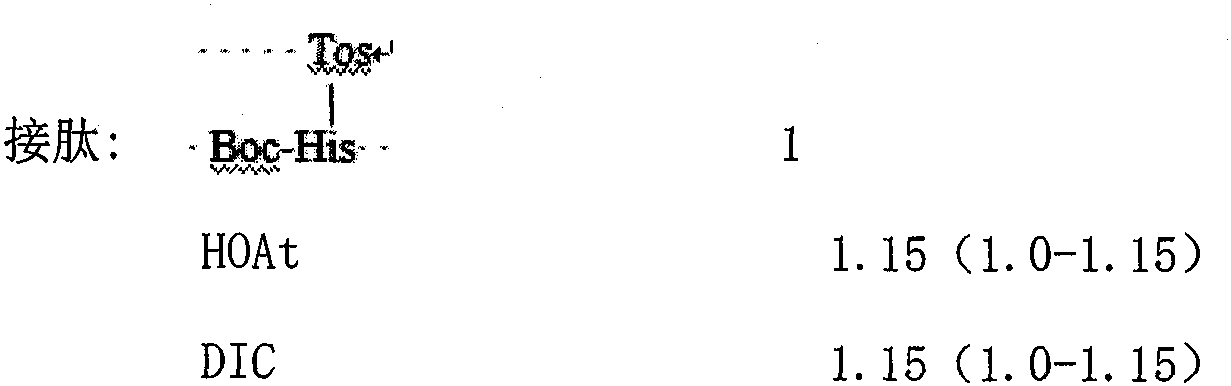

[0081] Embodiment 2 Incorporation of peptides (taking 300mmol input as an example)

[0082] 2.1. Dipeptide connection

[0083] Weigh 300mmol Place in a 10L reactor, wash with CH2Cl2 for 2 to 3 times, and drain.

[0084] Deprotection group: add 9-10N HCl / iPrOH780ml+CH2Cl2624ml+mercaptoethanol156ml, stir for 40 minutes, and drain. Washing: wash once with CH2Cl2 and drain; wash once with DMF and drain.

[0085] Neutralization: add triethylamine / CH2Cl2 (10 / 90) to wash once, and drain.

[0086] Washing: Wash once with DMF and drain; wash with CH2Cl2 three times until neutral, then drain.

[0087] Peptide: Boc-Arg·HCl(·H2O) 279.0 grams (295.92 grams) (900mmol)

[0088] HOBt 140.0 g (1035 mmol)

[0089] DCCI 213g (1035mmol)

[0090] Amino acid monomer; HOBt and DCCI were dissolved in 600ml of DMF respectively. Firstly, the solution of amino acid monomer was mixed with the solution of HOBt, stirred and reacted in ice bath for 30 minutes, then DCCI solution was added, and after...

Embodiment 3

[0131] Example 3 Aminolysis

[0132] 3.1. Aminolysis: put the above-mentioned dried nonapeptide resin into four 3L suction filtration bottles, add about 750ml of anhydrous methanol to each bottle, add about 1125ml of ethylamine, and seal it. Shake at room temperature for 24 hours, open the stopper under cooling, filter, wash the resin 4 times with methanol, and combine the filtrate and washings.

[0133] 3.2 Concentration: Concentrate the filtrate at 40~45℃ under reduced pressure (vacuum degree is -0.08~-0.1Mpa) to dryness, add methanol to dissolve and then concentrate under reduced pressure (vacuum degree is -0.08~-0.1Mpa) to dryness, repeat this process Three times, it becomes foamy, and concentrate I is obtained.

[0134] 3.3, transfer acetate: weigh the concentrate I, dissolve with 5 times the volume of methanol, precipitate with 50 times the volume of acetone at -22°C, filter, dissolve the filter cake with 5 times the volume of 50% acetic acid, concentrate under reduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com