Tetrabromobisphenol A molecularly-imprinted electrochemical sensor, and preparation method and application thereof

A technology of molecular imprinting and tetrabromobisphenol, which is applied in the direction of material electrochemical variables, etc., can solve the problems of more interference of response signals, inapplicability of on-site detection, and limited usage, so as to achieve high specific recognition ability and avoid other interference effects of substances, overcoming time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

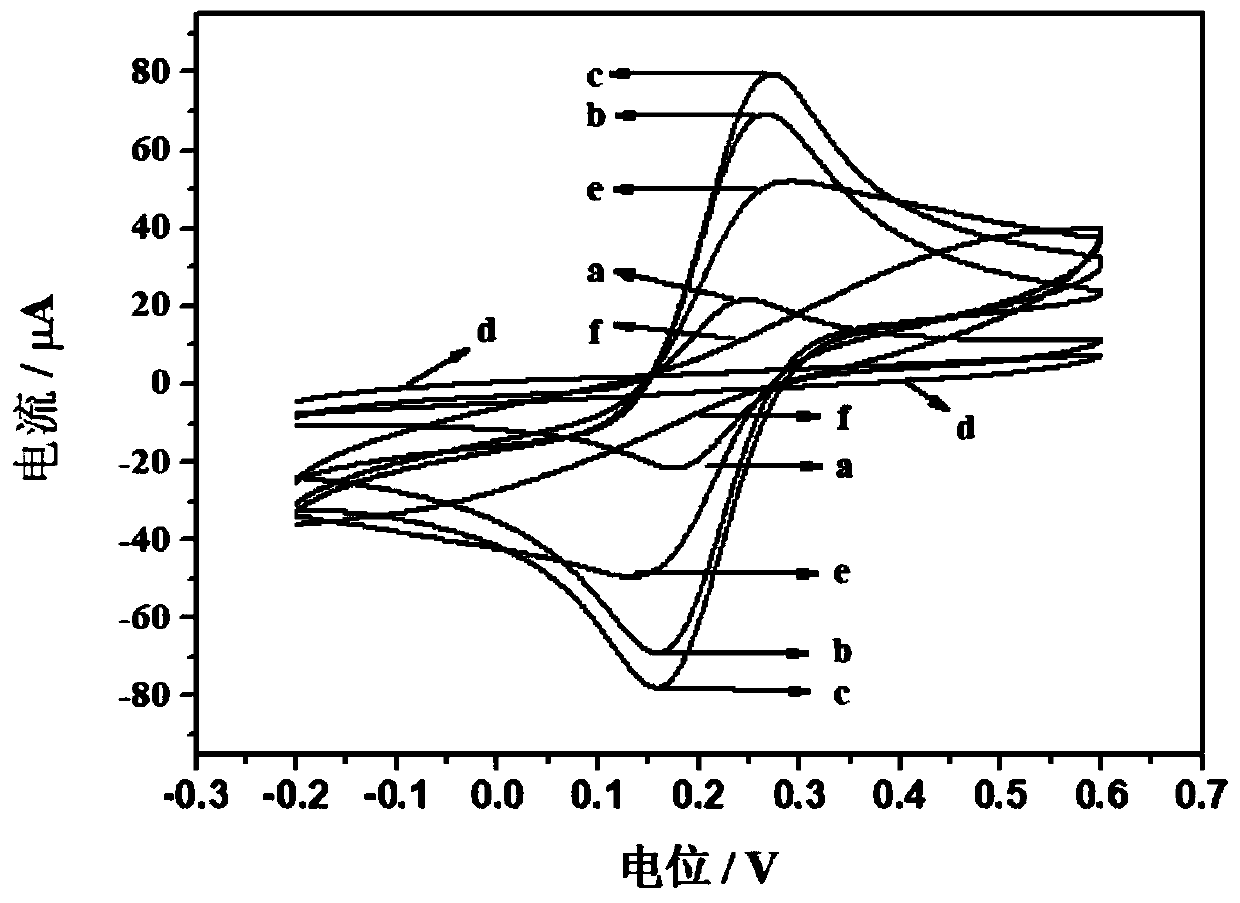

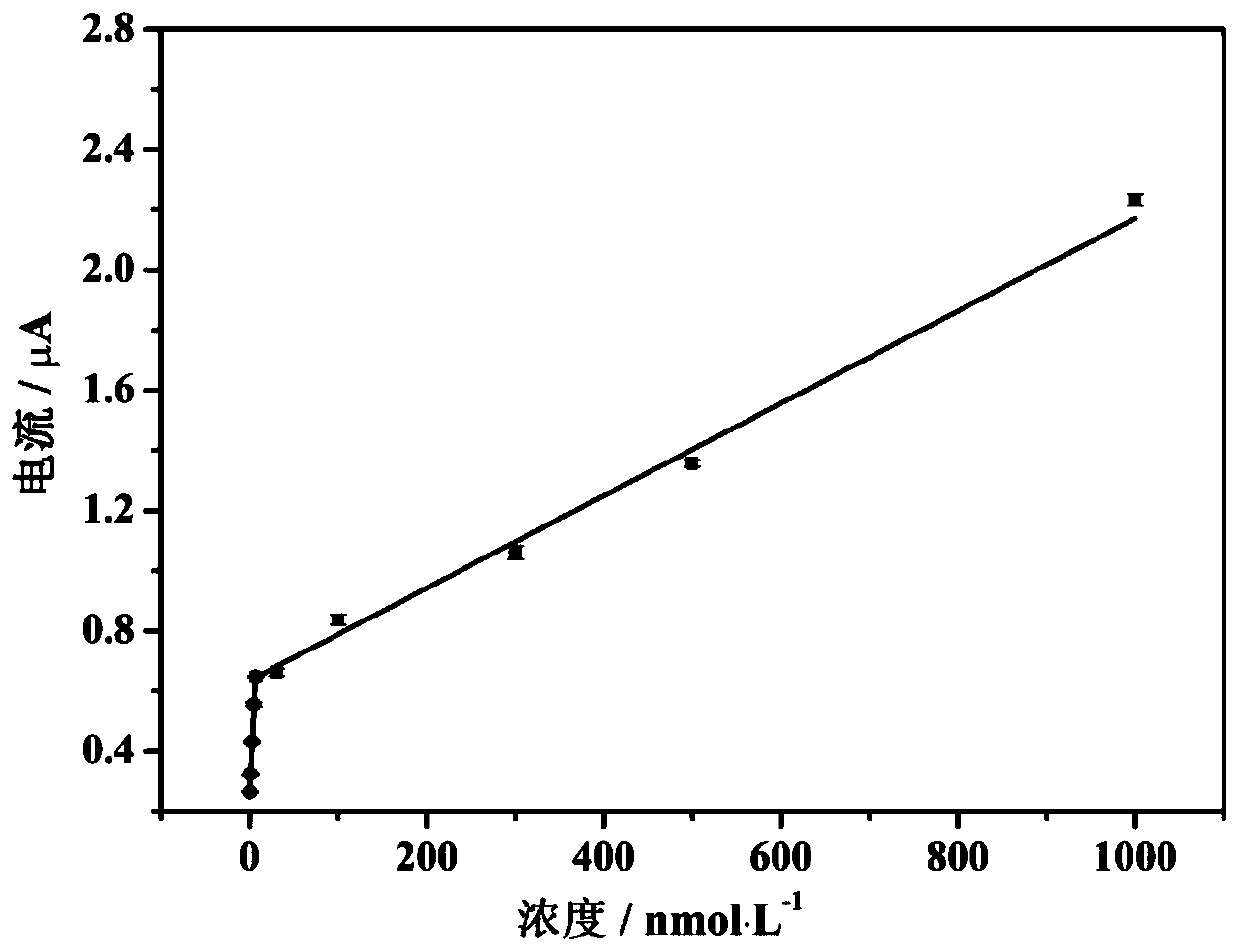

[0028] A method for preparing a molecularly imprinted electrochemical sensor modified by multi-walled carbon nanotubes / gold nanoparticles:

[0029] (1) The glassy carbon electrode (GCE, 3 mm in diameter) is sequentially made of Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder was polished on suede, and after cleaning, it was ultrasonically washed in ultrapure water and absolute ethanol for 30 seconds, and then dried with nitrogen gas for later use.

[0030] (2) Weigh 1 mg of multi-walled carbon nanotubes and ultrasonically disperse them in 1 mL of N,N-dimethylformamide for 2 hours to obtain a 1 mg / mL multi-walled carbon nanotube dispersion, pipette 9 μL The dispersed liquid was applied onto the surface of the electrode and allowed to dry naturally.

[0031] (3) Use MWCNTs / GCE as the working electrode, Ag / AgCl as the reference electrode, and platinum wire as the counter electrode to form a three-electrode working electrolytic cell; put the three electrodes into a cel...

Embodiment 2

[0046] A method for preparing a molecularly imprinted electrochemical sensor modified by multi-walled carbon nanotubes / gold nanoparticles:

[0047] (1) The glassy carbon electrode (GCE, 3 mm in diameter) is sequentially made of Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder was polished on suede, and after cleaning, it was ultrasonically washed in ultrapure water and absolute ethanol for 30 seconds, and then dried with nitrogen gas for later use.

[0048] (2) Weigh 0.5 mg of multi-walled carbon nanotubes and disperse ultrasonically in 1 mL of N,N-dimethylformamide for 2 hours to obtain a 0.5 mg / mL multi-walled carbon nanotube dispersion, pipette Take 5 μL of the dispersed solution and apply it to the surface of the electrode, and let it dry naturally.

[0049] (3) Use MWCNTs / GCE as the working electrode, Ag / AgCl as the reference electrode, and platinum wire as the counter electrode to form a three-electrode working electrolytic cell; put the three electrodes into ...

Embodiment 3

[0054] A method for preparing a molecularly imprinted electrochemical sensor modified by multi-walled carbon nanotubes / gold nanoparticles:

[0055] (1) The glassy carbon electrode (GCE, 3 mm in diameter) is sequentially made of Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder was polished on suede, and after cleaning, it was ultrasonically washed in ultrapure water and absolute ethanol for 30 seconds, and then dried with nitrogen gas for later use.

[0056] (2) Weigh 0.8 mg of multi-walled carbon nanotubes and disperse ultrasonically in 1 mL of N, N-dimethylformamide for 2 hours to obtain a 0.8 mg / mL multi-walled carbon nanotube dispersion, pipette Take 7 μL of the dispersed solution and apply it to the surface of the electrode, and let it dry naturally.

[0057] (3) Use MWCNTs / GCE as the working electrode, Ag / AgCl as the reference electrode, and platinum wire as the counter electrode to form a three-electrode working electrolytic cell; put the three electrodes into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com