Chain-type composite microbial agent and preparation method thereof

A technology of microbial agent and combination of microorganisms, applied in fertilizer mixture, fertilization device, application, etc., can solve problems such as being easily affected by the environment, single strain, unstable fertilizer efficiency, etc., to improve pest resistance, improve yield and quality, The effect of suppressing crop pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

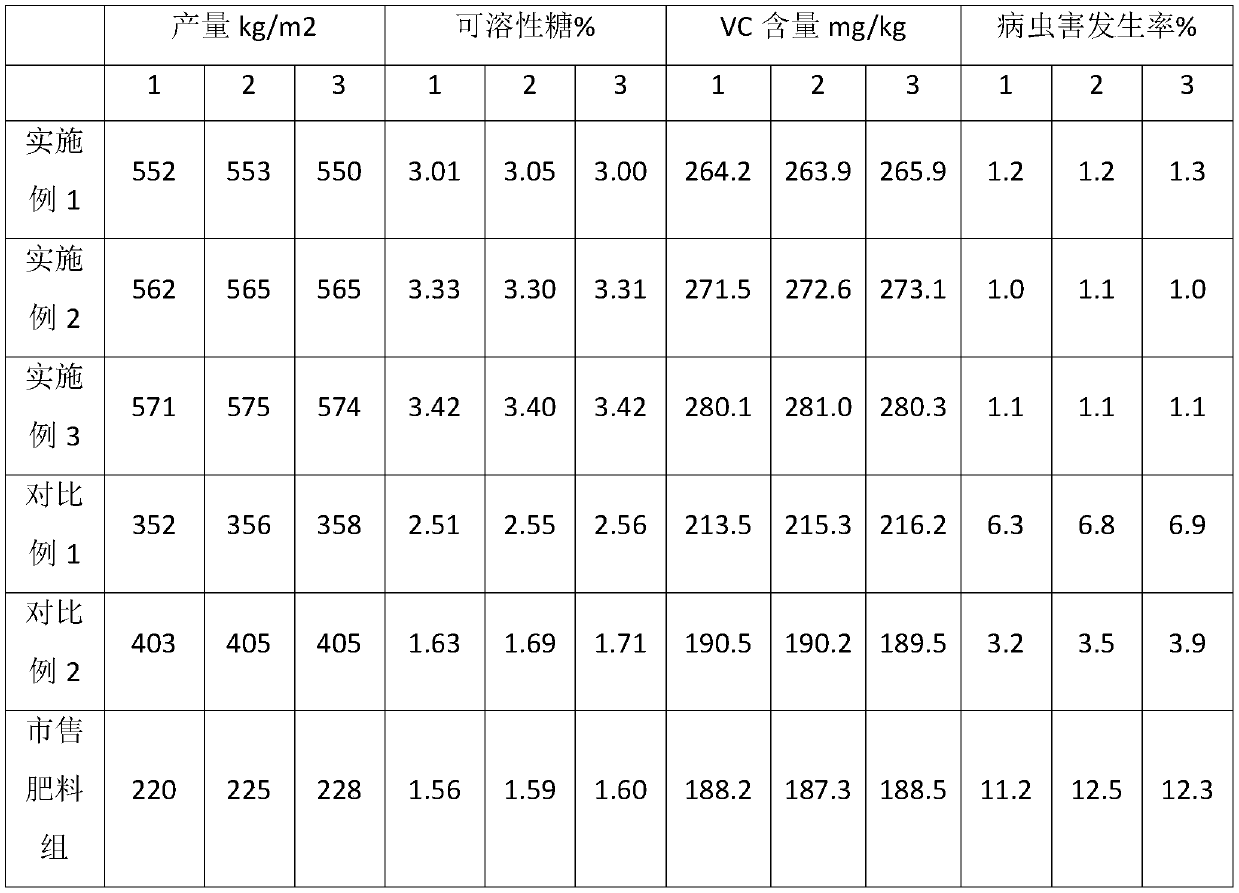

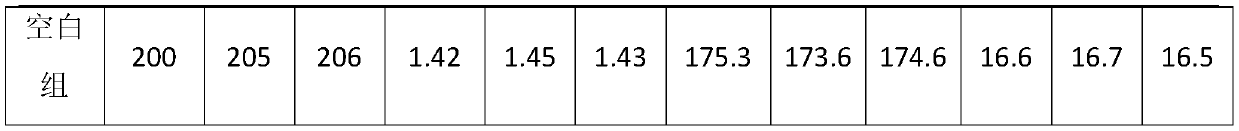

Embodiment 1

[0023] A chain type composite microbial bacterial agent, which is prepared from the following raw materials in parts by weight: 30 parts of combined microbial bacterial agent, 40 parts of modified diatomite, 20 parts of activated humic acid, 5 parts of medium and trace elements part; the combined microbial bacterial agent is made of Azotobacter rufosa, Bacillus megaterium, Actinomycetes, Bacillus licheniformis, photosynthetic bacteria, Bacillus thuringiensis and Paecilomyces lilacinus according to mass ratio 1:3:3:1.5:1.5 :1.8:1 mixed.

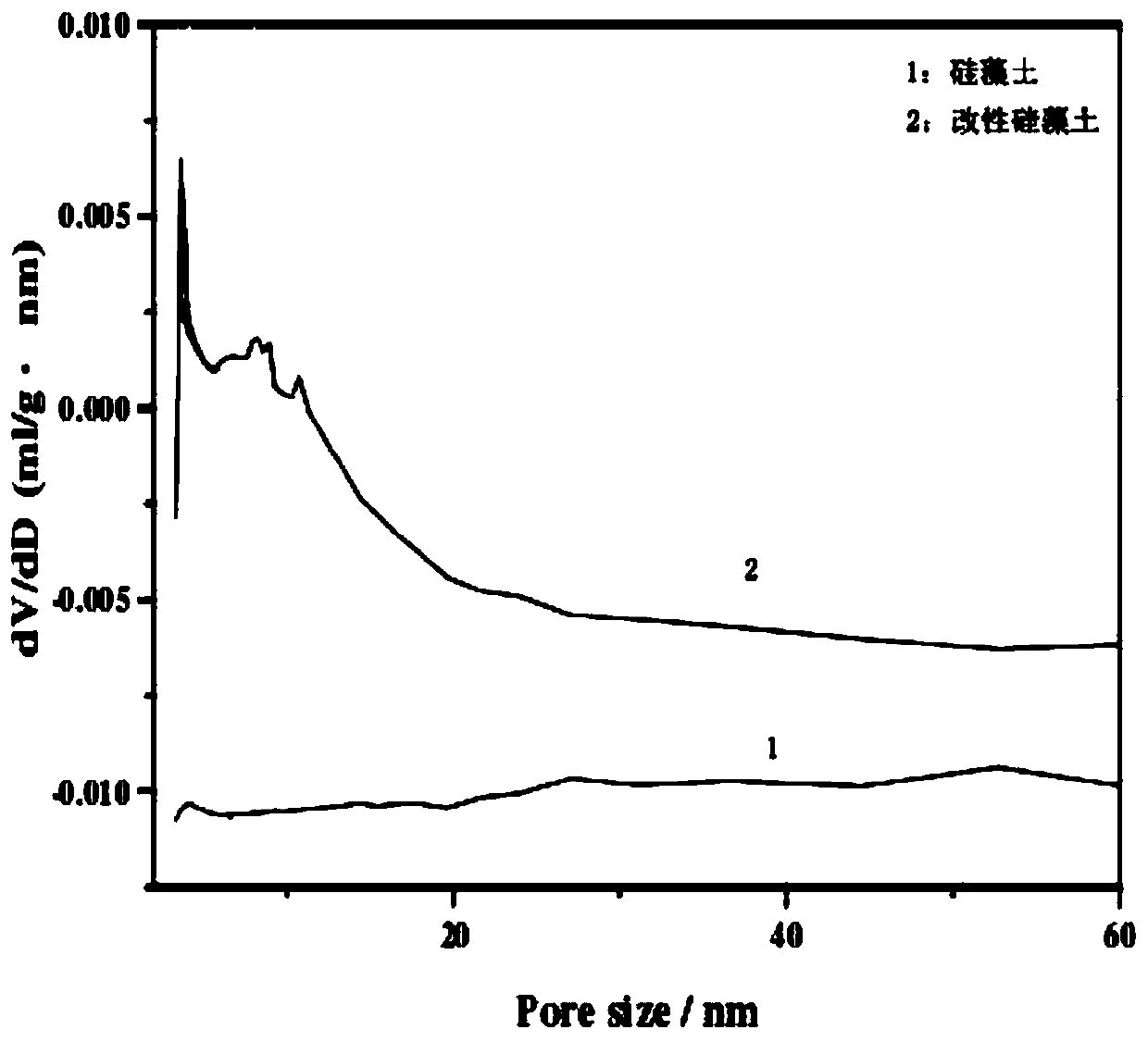

[0024] The modified diatomite is prepared by the following steps: take 10g of diatomite, disperse it in 100ml, 1mol / l Al(NO3)3 solution, stir evenly by magnetic force, then add 50ml, 1mol / l Al(NO3)3 dropwise. After NaOH solution was magnetically stirred for 24 hours, the suspension was vacuum-filtered, dried in vacuo at 60° C. and then ground to obtain modified diatomite.

[0025] The activated humic acid is prepared by the following steps: ...

Embodiment 2

[0036] A chain type composite microbial bacterial agent, which is prepared from the following raw materials in parts by weight: 50 parts of combined microbial bacterial agent, 60 parts of modified diatomite, 30 parts of activated humic acid, 8 parts of medium and trace elements part; the combined microbial bacterial agent is made of Azotobacter rufosa, Bacillus megaterium, Actinomycetes, Bacillus licheniformis, photosynthetic bacteria, Bacillus thuringiensis and Paecilomyces lilacinus according to mass ratio 1:3:3:1.5:1.5 :1.8:1 mixed.

[0037] The modified diatomite is prepared by the following steps: take 10g of diatomite, disperse it in 100ml, 1mol / l Al(NO3)3 solution, stir evenly by magnetic force, then add 50ml, 1mol / l Al(NO3)3 dropwise. After NaOH solution was magnetically stirred for 24 hours, the suspension was vacuum-filtered, dried in vacuo at 60° C. and then ground to obtain modified diatomite.

[0038] The activated humic acid is prepared by the following steps: ...

Embodiment 3

[0049] A chain type composite microbial bacterial agent, which is prepared from the following raw materials in parts by weight: 60 parts of combined microbial bacterial agent, 80 parts of modified diatomite, 40 parts of activated humic acid, and 10 parts of medium and trace elements part; the combined microbial bacterial agent is made of Azotobacter rufosa, Bacillus megaterium, Actinomycetes, Bacillus licheniformis, photosynthetic bacteria, Bacillus thuringiensis and Paecilomyces lilacinus according to mass ratio 1:3:3:1.5:1.5 :1.8:1 mixed.

[0050] The modified diatomite is prepared by the following steps: take 10g of diatomite, disperse it in 100ml, 1mol / l Al(NO3)3 solution, stir evenly by magnetic force, then add 50ml, 1mol / l Al(NO3)3 dropwise. After NaOH solution was magnetically stirred for 24 hours, the suspension was vacuum-filtered, dried in vacuo at 60° C. and then ground to obtain modified diatomite.

[0051] The activated humic acid is prepared by the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com