Quantum dot film and preparation method thereof, qled device and preparation method thereof

A quantum dot and quantum dot luminescence technology, which is applied in the field of quantum dots, can solve the problems of poor uniformity of quantum dot films, easy aggregation and sedimentation of ligands, and selectivity limitations, so as to expand the range of solvent selection, improve luminescence performance, and selectivity. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] On the one hand, an embodiment of the present invention provides a method for preparing a quantum dot film, comprising the following steps:

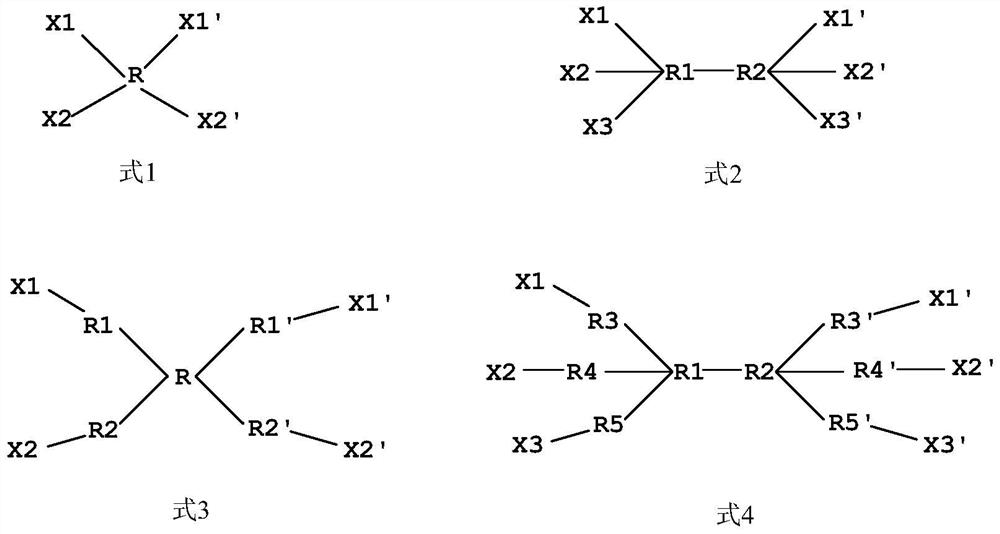

[0026] S01: Provide a quantum dot prefabricated film and a solution containing replacement ligands. The quantum dots in the quantum dot prefabricated film contain initial surface ligands. The general structural formula of the replacement ligand is: X-R;

[0027] Wherein, X is a functional group that can be combined with the surface of the quantum dot, and R is a hydrocarbon group or a hydrocarbon derivative with a conjugated group;

[0028] S02: performing liquid-phase ligand replacement on the quantum dot prefabricated film and the solution containing the replacement ligand, to obtain a quantum dot film with the replacement ligand bound to the surface of the quantum dot.

[0029] The preparation method of the quantum dot thin film provided by the embodiment of the present invention is to perform in-situ ligand replacement after t...

Embodiment 1

[0070] A method for preparing a quantum dot film, comprising the steps of:

[0071] Provide CdSe quantum dot prefabricated film and replacement ligand solution (aniline ethanol solution), the initial surface ligand in this quantum dot prefabricated film is OA;

[0072] Immerse the CdSe quantum dot prefabricated film into the replacement ligand solution, take it out after soaking for 10min, and then transfer it to a vacuum chamber, adjust the vacuum degree to 10Pa and maintain it for 30min to remove the uncoordinated ligand and solvent of the quantum dot film .

Embodiment 2

[0074] A method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0075] Dissolve aniline in ethanol to prepare a displacement ligand solution;

[0076] Print the PEDOT hole injection layer, TFB hole transport layer, and CdSe quantum dot film sequentially on the ITO anode, then immerse the CdSe quantum dot film in the above replacement ligand solution, take it out after soaking for 10min, and then transfer it to the vacuum chamber , adjust the vacuum degree to 10 Pa and maintain it for 30 minutes to remove uncoordinated ligands and solvents in the quantum dot film to obtain a quantum dot light-emitting layer;

[0077] A ZnO electron transport layer is printed on the ligand-exchanged quantum dot light-emitting layer, and finally an Al cathode is evaporated to obtain a positive-type structure quantum dot light-emitting diode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com