Method for removing arsenic in water through sulfite and ferric salt catalytic oxidation system

A sulfite, catalytic oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of complex operation process, low arsenic removal efficiency, high consumption of drugs, and achieve simple operation. , Significant economy, high arsenic removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

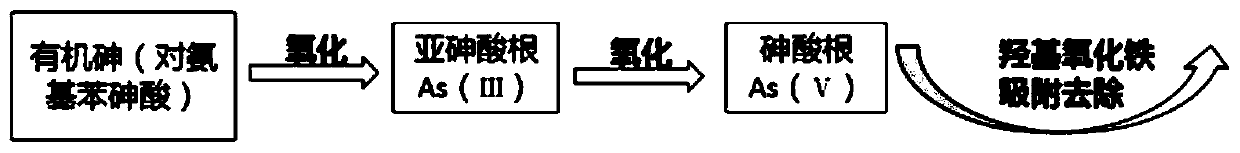

Problems solved by technology

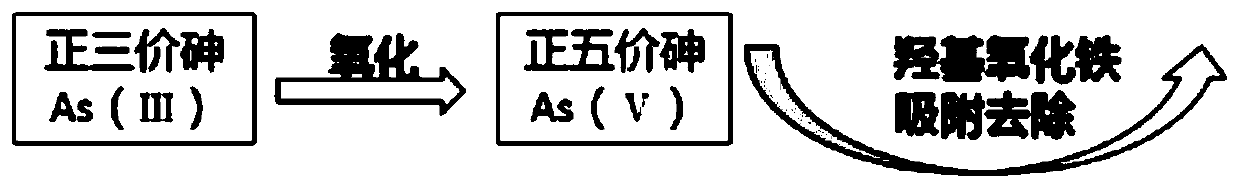

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiment 1: In this embodiment, a method for removing arsenic in water by using a sulfite and iron salt catalytic oxidation system is completed according to the following steps:

[0023] 1. Add sulfite and iron salt to the arsenic-containing water to be treated to obtain water to be treated containing sulfite and iron salt;

[0024] The concentration of sulfite in the untreated water containing sulfite and iron salt described in step 1 is 0.1mmol / L~2mmol / L;

[0025] The concentration of iron salt in the untreated water containing sulfite and iron salt described in step 1 is 0.01mmol / L~0.1mmol / L;

[0026] 2. Adjust the pH value of the water to be treated containing sulfite and iron salt to 4-6, then stir the reaction, and then let it stand at room temperature to obtain effluent, that is, complete a catalytic oxidation process using sulfite and iron salt Systematic method for removing arsenic from water.

[0027] The advantage of this implementation mode:

...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the sulfite described in step one is one of sodium sulfite, potassium sulfite, calcium sulfite, sodium bisulfite and potassium bisulfite or a mixture of several of them. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the iron salt described in step 1 is a mixture of one or both of ferric chloride and ferric sulfate. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com