Super-hydrophobic paint for old pump transformation and preparation method and application of paint

A technology of super-hydrophobic paint and treatment method, applied in the field of super-hydrophobic paint for retrofitting old pumps and its preparation, can solve the problems of high energy consumption, volume loss, hydraulic loss and other problems of the pump body, so as to improve the service life and reduce friction. The effect of blocking and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

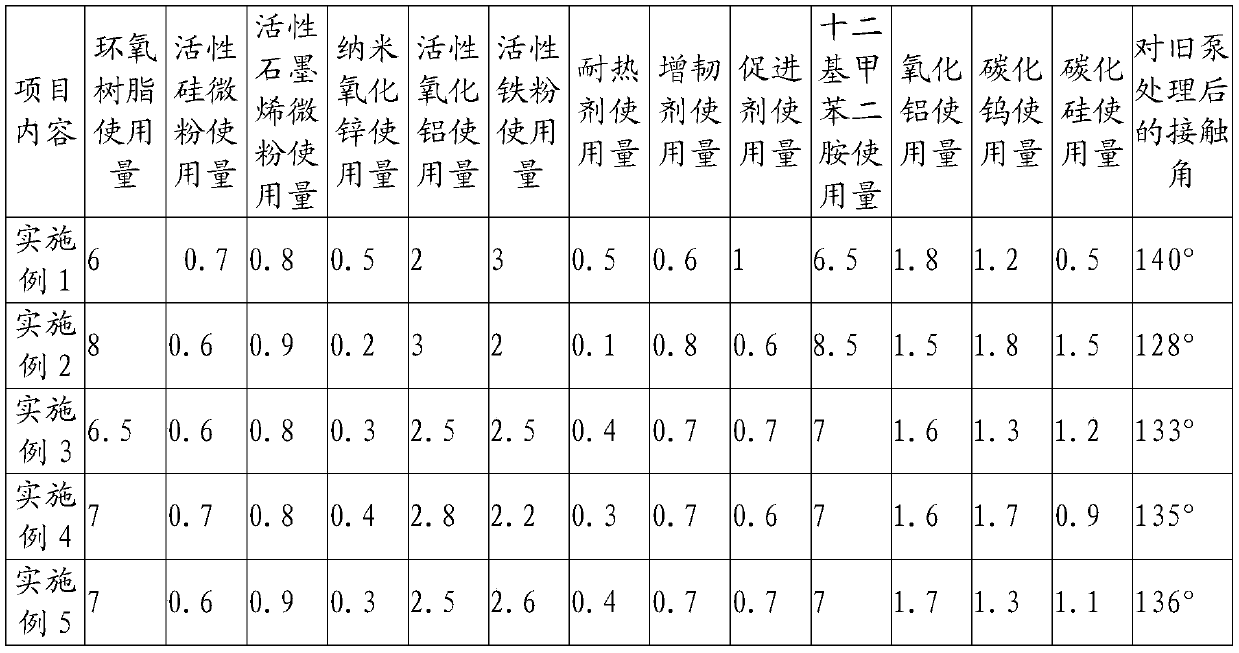

Embodiment 1

[0036] Superhydrophobic coating 1 was prepared by the following recipe:

[0037] The modified resin components include: 6 parts of epoxy resin, 0.7 parts of active silicon micropowder, 0.8 part of active graphene micropowder, 0.5 part of nano-zinc oxide, 2 parts of activated alumina, 3 parts of active iron powder, 0.5 part of heat-resistant agent, 0.6 parts of toughening agent, 1 part of accelerator;

[0038] The modified curing agent components include: 6.5 parts of dodecyltoluenediamine, 1.8 parts of aluminum oxide, 1.2 parts of tungsten carbide, and 0.5 parts of silicon carbide.

Embodiment 2

[0040] Superhydrophobic coating 2 was prepared by the following recipe:

[0041] The modified resin components include: 8 parts of epoxy resin, 0.6 parts of active silicon micropowder, 0.9 part of active graphene micropowder, 0.2 part of nano-zinc oxide, 3 parts of activated alumina, 2 parts of active iron powder, 0.1 part of heat-resistant agent, 0.8 part of toughening agent, 0.6 part of accelerator;

[0042] The components of the modified curing agent include: 8.5 parts of dodecyltoluenediamine, 1.5 parts of aluminum oxide, 1.8 parts of tungsten carbide, and 1.5 parts of silicon carbide.

Embodiment 3

[0044] Superhydrophobic coating 3 was prepared by the following recipe:

[0045] The modified resin components include: 6.5 parts of epoxy resin, 0.6 parts of active silicon micropowder, 0.8 part of active graphene micropowder, 0.3 part of nano-zinc oxide, 2.5 parts of activated alumina, 2.5 parts of active iron powder, 0.4 part of heat-resistant agent, 0.7 part of toughening agent, 0.7 part of accelerator;

[0046] The modified curing agent components include: 7 parts of dodecyltoluenediamine, 1.6 parts of aluminum oxide, 1.3 parts of tungsten carbide, and 1.2 parts of silicon carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com