Application of compound as scintillant material and preparation method thereof

A scintillator material and compound technology, applied in silver compounds, copper compounds, silver compounds, etc., can solve the problems of moderate radiation resistance, high price, and easy generation of impurities, and achieve weak self-absorption, large atomic number, light high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

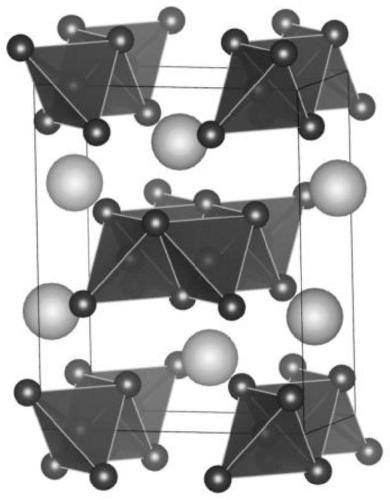

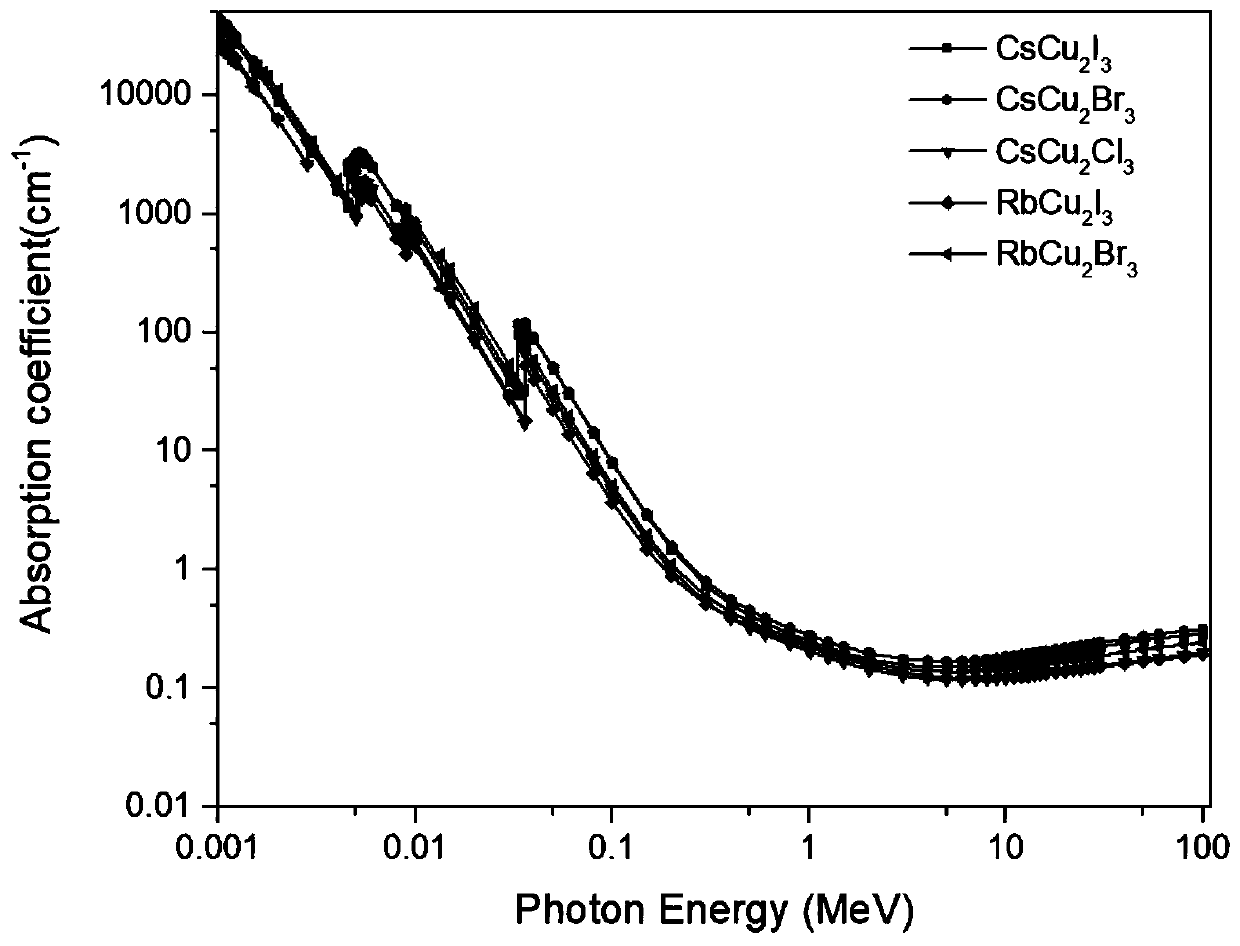

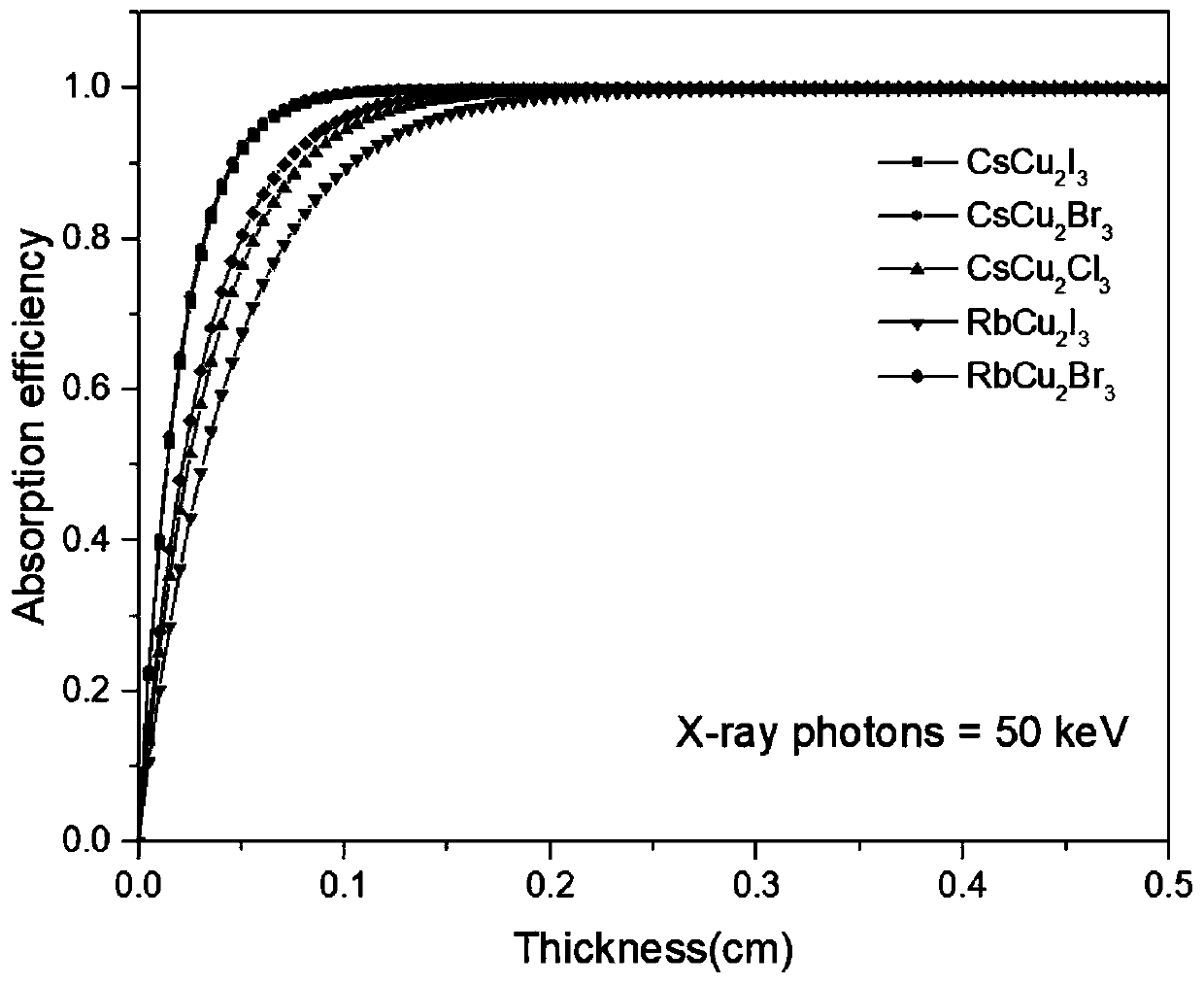

Method used

Image

Examples

Embodiment 1

[0025] A new type of scintillator material, its specific preparation steps are as follows:

[0026] Step 1: Weigh 1.8187g cesium iodide (CsI) and 2.6667g cuprous iodide (CuI) in a mortar, mix and grind evenly and pour into a centrifuge tube, then add 10mL of dimethylsulfoxide to the centrifuge tube ( DMSO), shake and dissolve in the glove box, and use it as the precursor solution;

[0027] Step 2: Add the anti-solvent--30mL of dichloromethane into the precursor solution obtained above, and shake to make the anti-solvent and the precursor solution fully mix and react;

[0028] Step 3: After the white powder is completely precipitated, place the centrifuge tube in a centrifuge, centrifuge at a speed of 7000rpm / min for 10 minutes, and remove the supernatant.

[0029] Step 4: Add 5 mL of dichloromethane dropwise to the precipitate to wash, centrifuge at 5500 rpm / min for 5 minutes, remove the supernatant, and repeat once more.

[0030] Step 5: Place the precipitate in a drying to...

Embodiment 2

[0032] A new type of scintillator material, its specific preparation steps are as follows:

[0033] Step 1: Weigh 1.4897g cesium bromide (CsBr) and 1.0042g cuprous bromide (CuBr) in a mortar, mix and grind evenly and pour into a centrifuge tube, then add 12mL of dimethyl sulfoxide ( DMSO), shake and dissolve in the glove box, and use it as the precursor solution;

[0034] Step 2: Add the anti-solvent—40mL of dichloromethane into the precursor solution obtained above, and shake to make the anti-solvent and the precursor solution fully mix and react;

[0035] Step 3: After the yellow powder is completely precipitated, place the centrifuge tube in a centrifuge, centrifuge at a speed of 7000rpm / min for 10 minutes, and remove the supernatant.

[0036] Step 4: Add 6 mL of dichloromethane dropwise to the precipitate to wash, centrifuge at 5500 rpm / min for 5 minutes, remove the supernatant, and repeat once more.

[0037] Step 5: Place the precipitate in a drying tower and drain it t...

Embodiment 3

[0039] A new type of scintillator material, its specific preparation steps are as follows:

[0040] Step 1: Weigh 1.1785g cesium chloride (CsCl) and 0.6930g cuprous chloride (CuCl) in a mortar, mix and grind evenly and pour into a centrifuge tube, then add 10mL of dimethylsulfoxide ( DMSO), shake and dissolve in the glove box, and use it as the precursor solution;

[0041] Step 2: Add the anti-solvent--30mL of dichloromethane into the precursor solution obtained above, and shake to make the anti-solvent and the precursor solution fully mix and react;

[0042] Step 3: After the white powder is completely precipitated, place the centrifuge tube in a centrifuge, centrifuge at a speed of 7000rpm / min for 10 minutes, and remove the supernatant.

[0043] Step 4: Add 5 mL of dichloromethane dropwise to the precipitate to wash, centrifuge at 5500 rpm / min for 5 minutes, remove the supernatant, and repeat once more.

[0044] Step 5: Place the precipitate in a drying tower to dry it, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com