Method for determining content of platinum in fluorine polymer

A technology of fluoropolymer and determination method, which is applied in the field of chemical analysis, can solve the problems of low platinum element content determination, inability to use and difficult to dissolve, etc., and achieve the effect of convenient and quick digestion and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

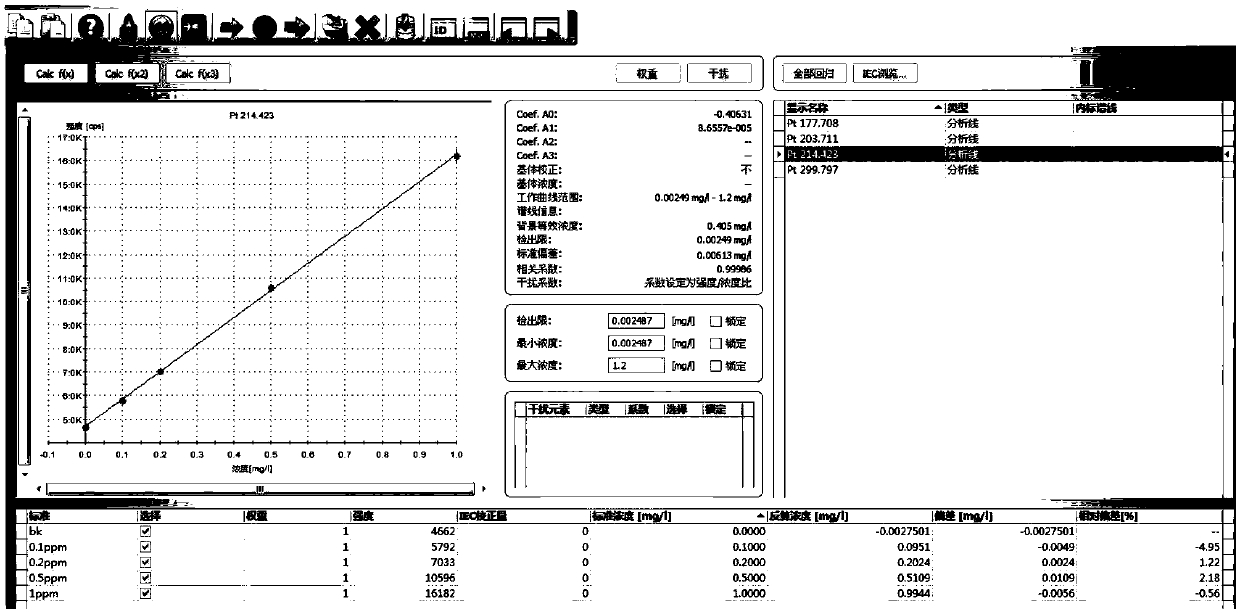

[0054] In the above step S03, the platinum element is detected on the solution sample to be tested by using the ICP-OES method, which can be carried out by using a commonly used ICP-OES testing instrument on the market. As a specific embodiment, the ICP-OES test instrument adopts the German SPECTRO ARCOS full-spectrum direct-reading plasma emission spectrometer; the ICP-OES test conditions are:

[0055] Instrument parameters: observation height 2mm; atomizer flow rate 0.75L / min; power: 1430W; plasma gas 12L / min; auxiliary gas flow rate 0.9L / min; reference wavelength, platinum 214.423nm.

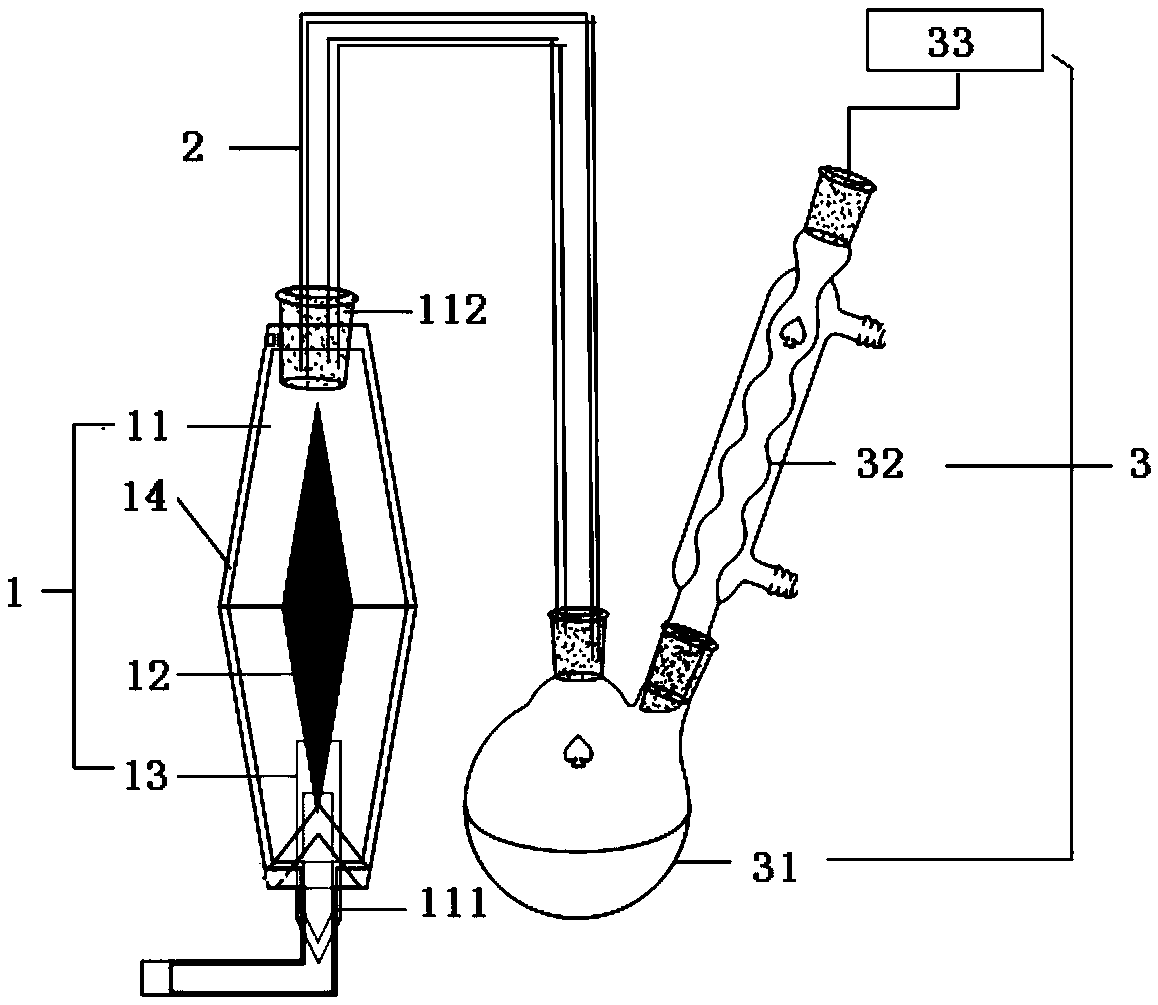

[0056] In the examples of the present invention, the platinum content in the fluoropolymer is determined by a fluorine gas high-temperature dynamic digestion device. preferred, such as figure 1 As shown, the high-temperature dynamic digestion device includes a combustion system 1 and an ash collection system 3 communicated through a calcium fluoride glass tube 2, wherein the combustion syste...

Embodiment 1

[0066] Preparation of standard solution:

[0067] Use the above-mentioned 1000mg / L platinum standard solution to dilute step by step to 0.1mg / L, 0.2mg / L, 0.5mg / L, 1.0mg / L as the standard solution, and draw the platinum content to make a standard curve, such as figure 2 shown. The linear coefficient of the standard curve is 0.99986, and the detection limit is 0.0025mg / L (solution concentration).

Embodiment 2

[0069] A method for measuring platinum content in fluoropolymers, said method is high-temperature dynamic digestion of fluorine gas, comprising the following steps:

[0070] S21. First pass 30% fluorine-nitrogen mixed gas into the digestion device at a flow rate of 20ml / min, and then heat the temperature of the heating zone to around 2500°C; The gas burns rapidly, and the fluoropolymer turns into carbon tetrafluoride, hydrogen fluoride and other gases at high temperature and is burned;

[0071] S22. After the sample is burned, use 100ml of aqua regia to dissolve and clean, the combustion chamber, the glass tube, the collection bottle, and the condenser tube 32 to prepare a solution sample to be tested containing platinum solution;

[0072] S23. Using the ICP-OES method to detect the platinum element in the solution sample to be tested, and obtain the content of the platinum element in the sample. The ICP-OES test instrument adopts the German SPECTRO ARCOS full-spectrum direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com