Method for improving electricity generation and sensing performance of microbial fuel cell

A fuel cell and microorganism technology, applied in the field of microbial electrochemistry and biosensing, can solve the problems of poor sensing performance of microbial fuel cell sensor, increase the sensing application range of MFC sensor, narrow working temperature range, etc. The effect of application temperature range, improved electrochemical performance, and improved sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

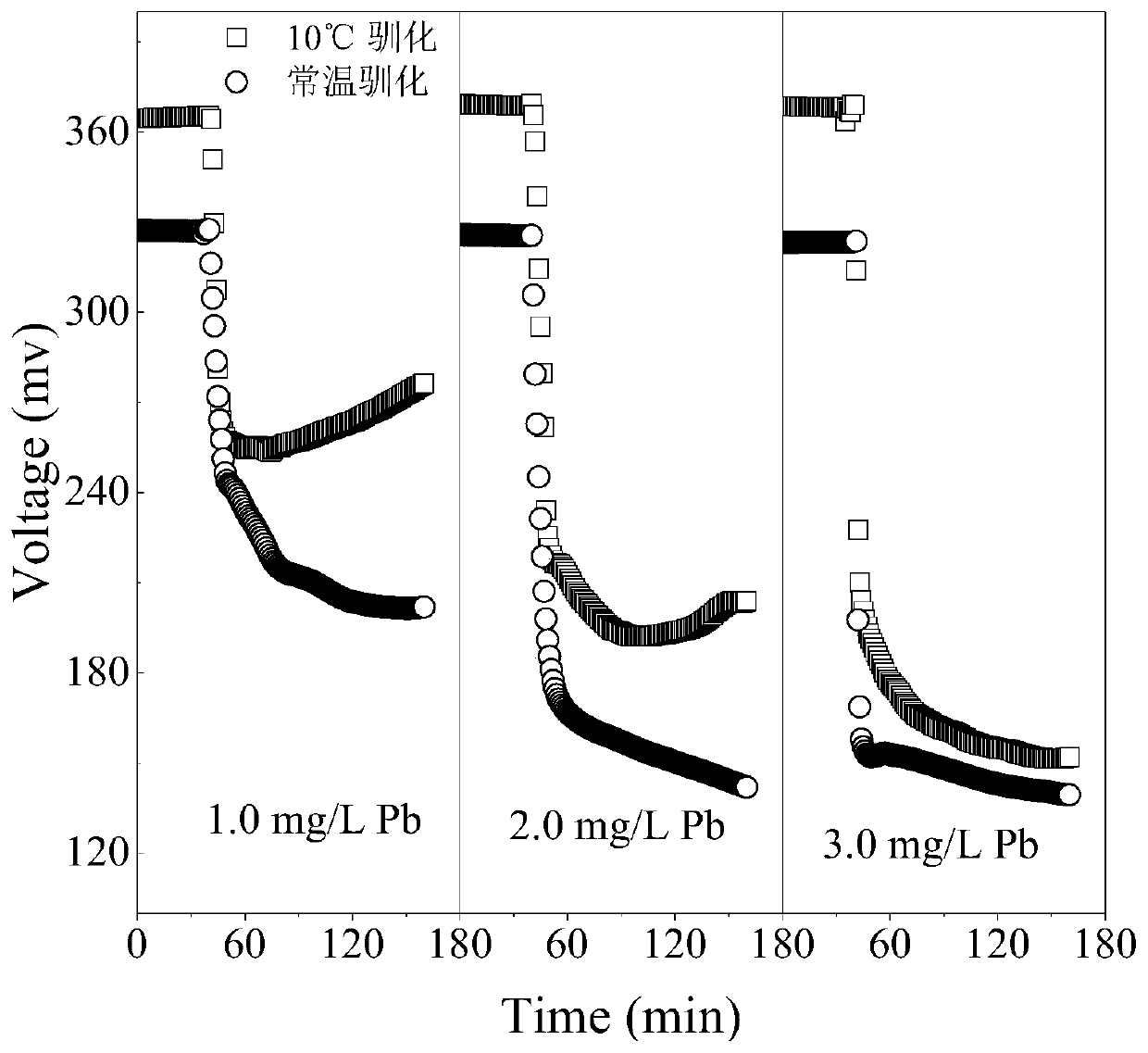

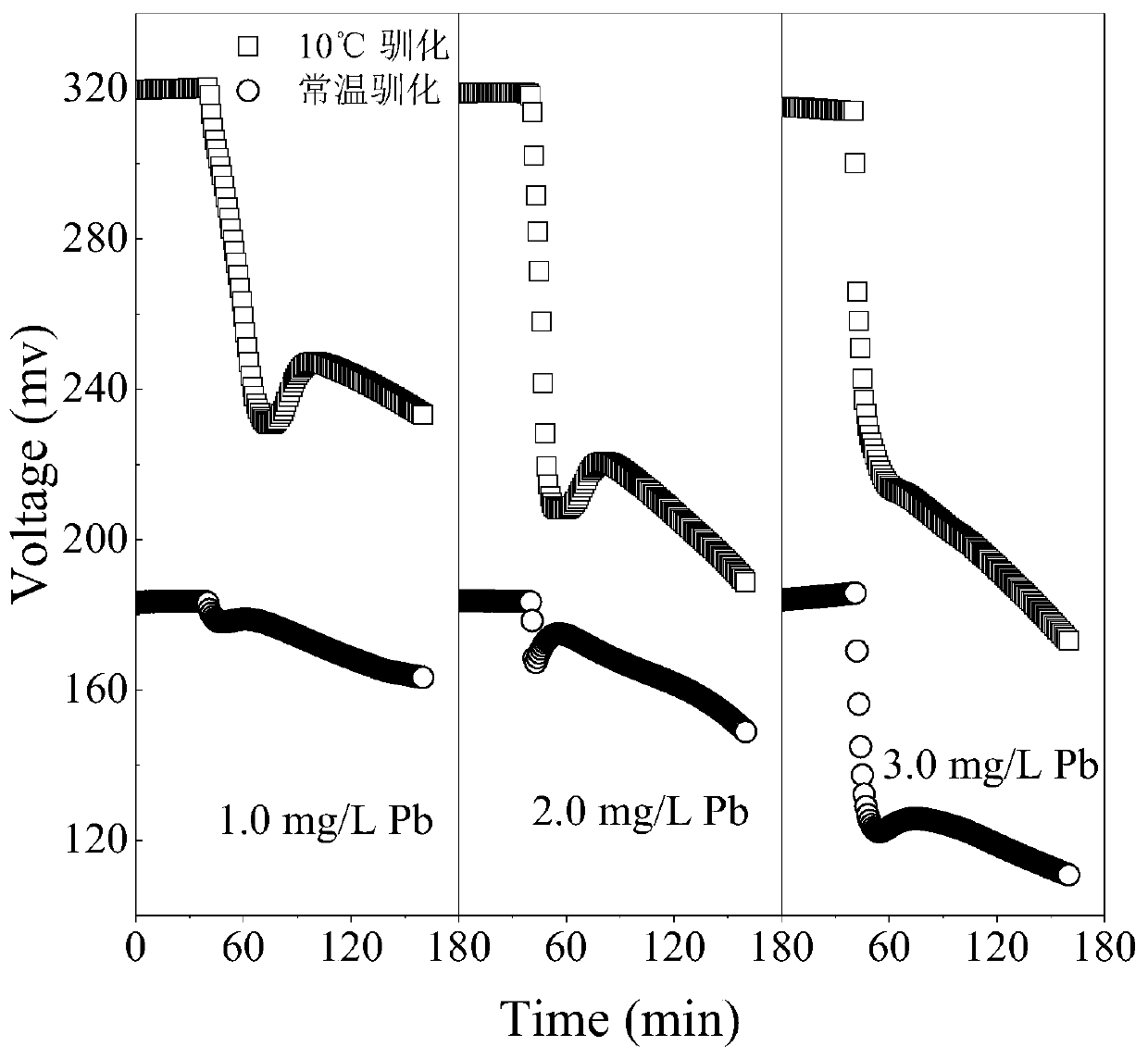

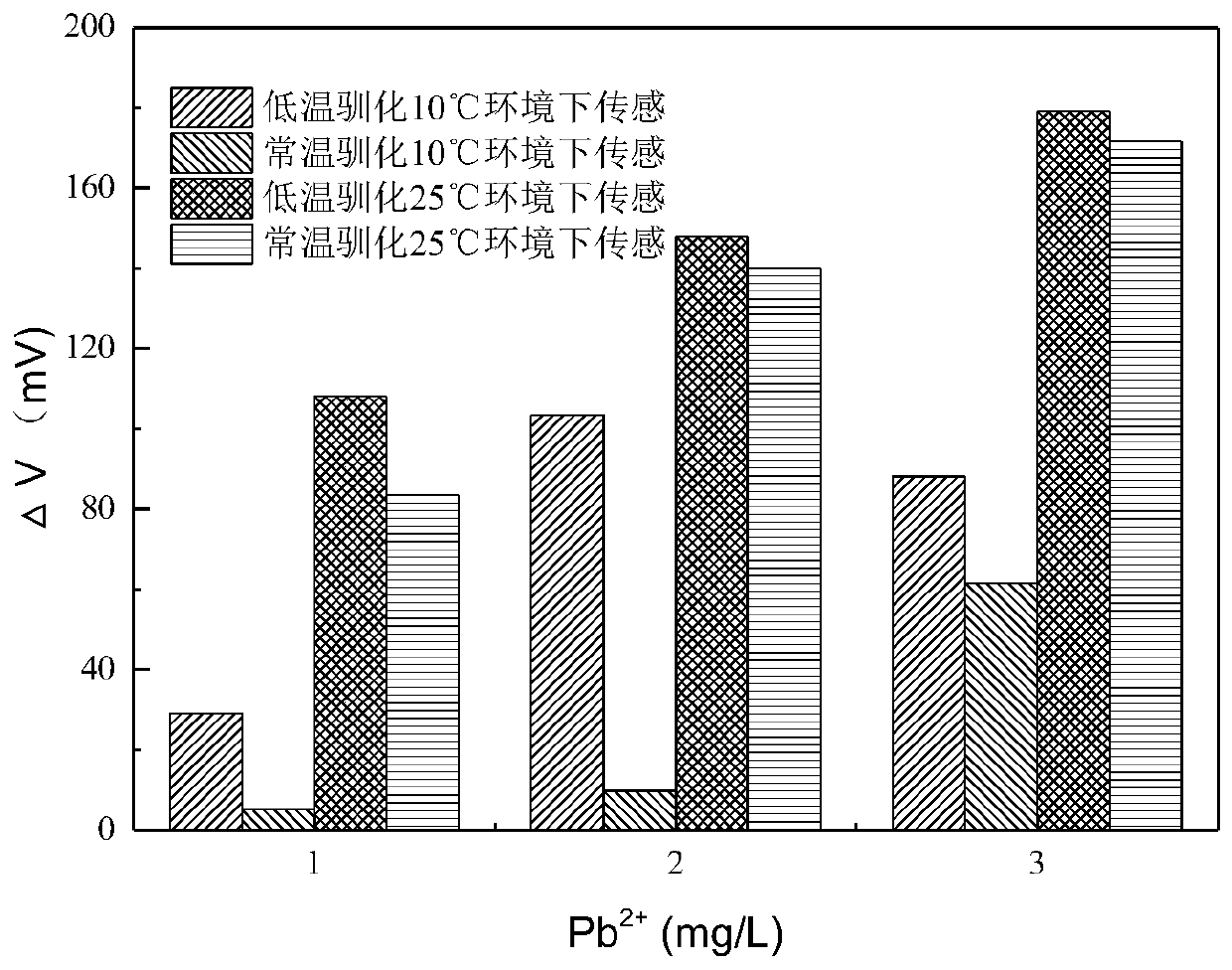

Examples

Embodiment 1

[0044] (1) Preparation of graphite plate anode for microbial fuel cell: Cut the graphite plate into small squares of 2cm × 2cm × 0.5cm, and after polishing with 800-mesh and 1200-mesh sandpaper, add an appropriate amount of 0.05 μm polished aluminum powder and graphite to the polishing table. The electrode is polished by the figure-of-eight method, and after being washed with deionized water, a clean graphite plate electrode is obtained. Immerse the clean graphite plate in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 minutes, and dry in an oven at 70°C for 4 hours to obtain the graphite plate anode of the microbial fuel cell.

[0045] (2) Preparation of air cathode for microbial fuel cell: Cut 50-mesh stainless steel mesh into a circle with a diameter of 3.8 cm, immerse in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 min, and dry in an oven at 70°C for 4 h for later use. Weigh 5g of...

Embodiment 2

[0050] (1) Preparation of graphite plate anode for microbial fuel cell: Cut the graphite plate into small squares of 2cm × 2cm × 0.5cm, and after polishing with 800-mesh and 1200-mesh sandpaper, add an appropriate amount of 0.05 μm polished aluminum powder and graphite to the polishing table. The electrode is polished by the figure-of-eight method, and after being washed with deionized water, a clean graphite plate electrode is obtained.

[0051] Immerse the clean graphite plate in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 minutes, and dry in an oven at 70°C for 4 hours to obtain the graphite plate anode of the microbial fuel cell.

[0052] (2) Preparation of air cathode for microbial fuel cell: Cut 50-mesh stainless steel mesh into a circle with a diameter of 3.8 cm, immerse in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 min, and dry in an oven at 70°C for 4 h for later use. We...

Embodiment 3

[0057] (1) Preparation of graphite plate anode for microbial fuel cell: Cut the graphite plate into small squares of 2cm × 2cm × 0.5cm, and after polishing with 800-mesh and 1200-mesh sandpaper, add an appropriate amount of 0.05 μm polished aluminum powder and graphite to the polishing table. The electrode is polished by the figure-of-eight method, and after being washed with deionized water, a clean graphite plate electrode is obtained.

[0058] Immerse the clean graphite plate in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 minutes, and dry in an oven at 70°C for 4 hours to obtain the graphite plate anode of the microbial fuel cell.

[0059] (2) Preparation of air cathode for microbial fuel cell: Cut 50-mesh stainless steel mesh into a circle with a diameter of 3.8 cm, immerse in acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean each for 15 min, and dry in an oven at 70°C for 4 h for later use. We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com