Reduced bimetallic diesel oil hydrogenation conversion catalyst

A hydroconversion and bimetal technology, which is applied to the catalyst for the hydroconversion of diesel fused-ring aromatic hydrocarbons and the catalyst for the hydroconversion of reduced bimetallic diesel, can solve the problems of limited range and inability to remove aromatics, and simplifies the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

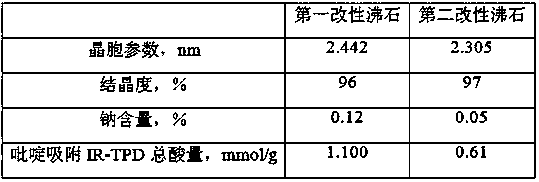

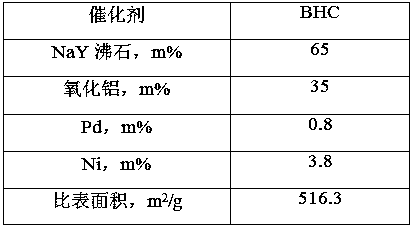

Method used

Image

Examples

Embodiment 1

[0049] Take 40ml of Catalyst C (31.3g) and put it into the reactor of 100ml single-tube hydrogen once-through device, raise the temperature and vacuumize the device, and dry it for 4 hours at a temperature of 250°C and a vacuum degree > 66kPa; Nitrogen with % oxygen breaks the vacuum and heats up to 400°C at a rate of 20°C / h under the conditions of pressure 0.1MPa and tail gas volume 48NL / h. h, under the condition of constant temperature for 4 hours, replace the nitrogen with a mixed gas of 70v% hydrogen and 30v% argon, adjust the pressure to 0.1MPa, the exhaust gas volume to 28NL / h, raise the temperature to 510°C, and perform reduction for 48 hours; at 30°C / hour Cool down to 420°C at a rate of 15°C / h; adjust the pressure to 0.5MPa, circulate gas volume to 48NL / h, inject 320mL of cyclohexane containing 0.3g of quinoline in 4 hours; raise the temperature to 520°C at a rate of 15°C / h for 0.5h, The reduced bimetallic diesel hydroconversion catalyst RC1 was obtained, and its prope...

Embodiment 2

[0053] Except that the consumption of quinoline is changed into 0.6 gram, other operation is the same as embodiment 1. Catalyst RC2 is obtained.

Embodiment 3

[0056] The catalyst of above embodiment is used for diesel oil hydroconversion experiment:

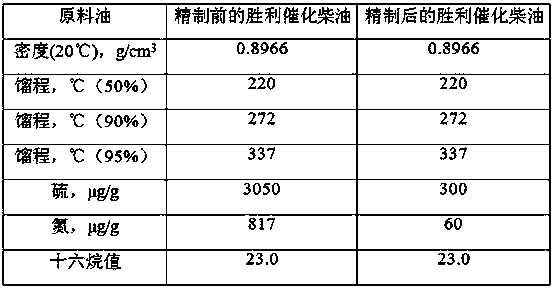

[0057] Presulfurize the catalysts of Examples 1 to 3; keep the temperature at 420°C, adjust the pressure to 0.5MPa, the circulation gas volume to 48NL / h, the amount of sulfurized oil to enter 80mL / h, and inject 320mL of 0.032g of sulfur into the ring in 4 hours. Hexane; cool down to 320°C at a speed of 15°C / h, adjust the pressure to 8.0MPa, the circulation gas volume to 48NL / h, and feed the raw material oil at the rate of 45g / h. 360°C fraction. After running for 300 hours, samples were taken for correlation analysis. The properties of the raw oil used in the test are shown in Table 3, and the test results are shown in Table 4.

[0058] Table 3. Raw oil properties

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com