Sodium ion solid electrolyte and preparation method thereof

A solid electrolyte and sodium ion technology, applied in the field of sodium batteries, can solve the problems of high cost of all solid electrolytes, low safety of liquid electrolytes, and large interface resistance, and achieve improved economic efficiency and performance, high energy density, and low interface resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

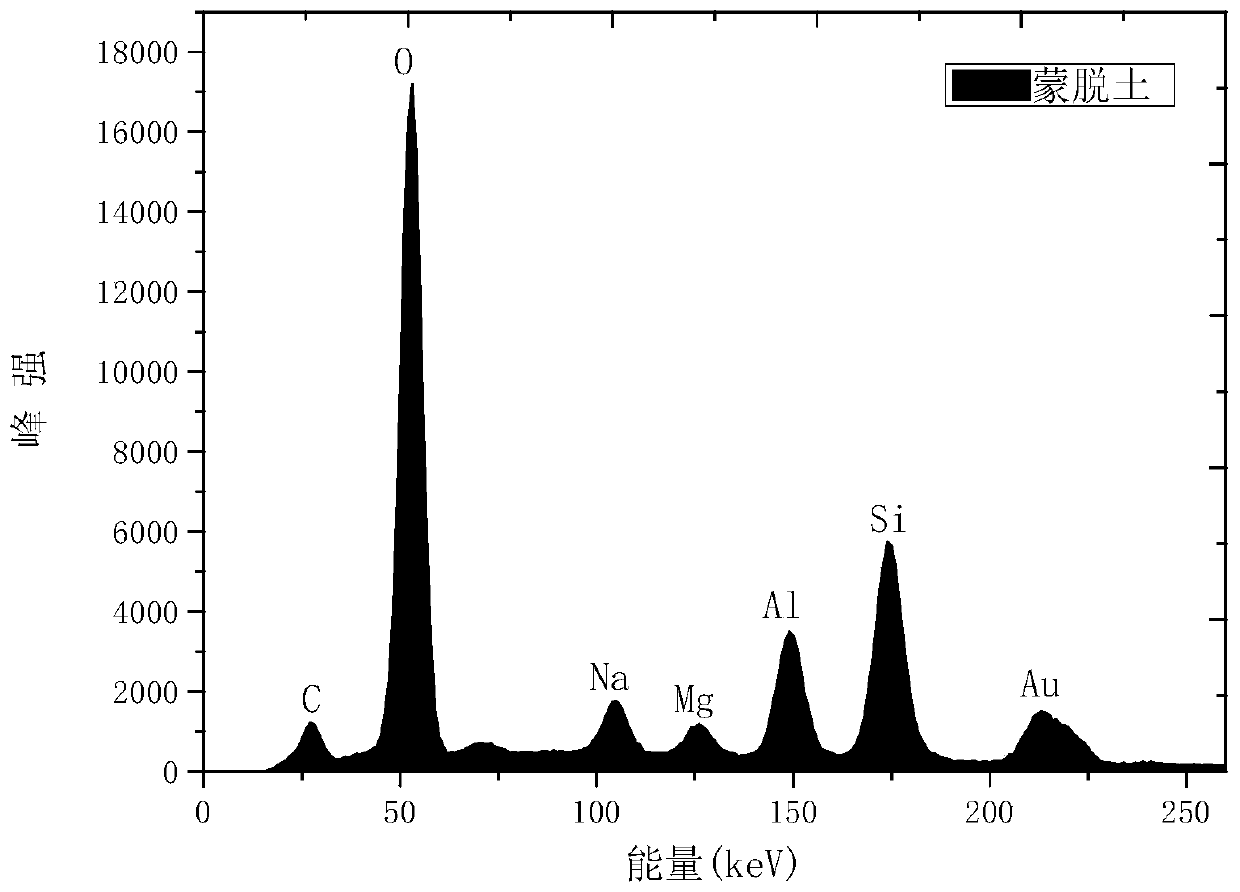

[0036] As a sodium ion solid electrolyte in an embodiment of the present invention, the sodium ion solid electrolyte includes the following components: ionic liquid, montmorillonite and sodium salt, and the sodium ion solid electrolyte is prepared and heated;

[0037] The ionic liquid is 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt;

[0038] The sodium salt is sodium bistrifluoromethanesulfonylimide;

[0039] The mass concentration of the sodium salt in the mixture of the ionic liquid and the sodium salt in the sodium ion solid electrolyte is 5%;

[0040] The mass ratio of the total mass of the sodium salt and the ionic liquid to the montmorillonite is 2.

[0041] A method for preparing a sodium ion solid state electrolyte of the present embodiment, the method comprising the following steps:

[0042] (1) Under normal temperature and pressure, in an argon-filled glove box (oxygen and water content less than 0.1ppm), the ionic liquid 1-ethyl-3-methylimidazole...

Embodiment 2

[0047] As a sodium ion solid electrolyte of the embodiment of the present invention, the difference between the present invention and Embodiment 1 is: the mass concentration of the sodium salt in the mixture of the ionic liquid and the sodium salt in the sodium ion solid electrolyte is 95%;

[0048] The mass ratio of the total mass of the sodium salt and the ionic liquid to the montmorillonite is 1.09.

[0049] Characterization of the sodium ion solid electrolyte of this example: use Kester’s electrochemical workstation to test performance at a room temperature of 25°C, and the frequency range is 1-10 6 Hz.

[0050] After fitting, the ionic conductivity of the solid electrolyte of this embodiment is 4.8×10-4 S / cm.

Embodiment 3

[0052] As a sodium ion solid electrolyte of the embodiment of the present invention, the difference between the present invention and Embodiment 1 is: the mass concentration of the sodium salt in the mixture of the ionic liquid and the sodium salt in the sodium ion solid electrolyte is 15%;

[0053] The mass ratio of the total mass of the sodium salt and the ionic liquid to the montmorillonite is 1.09.

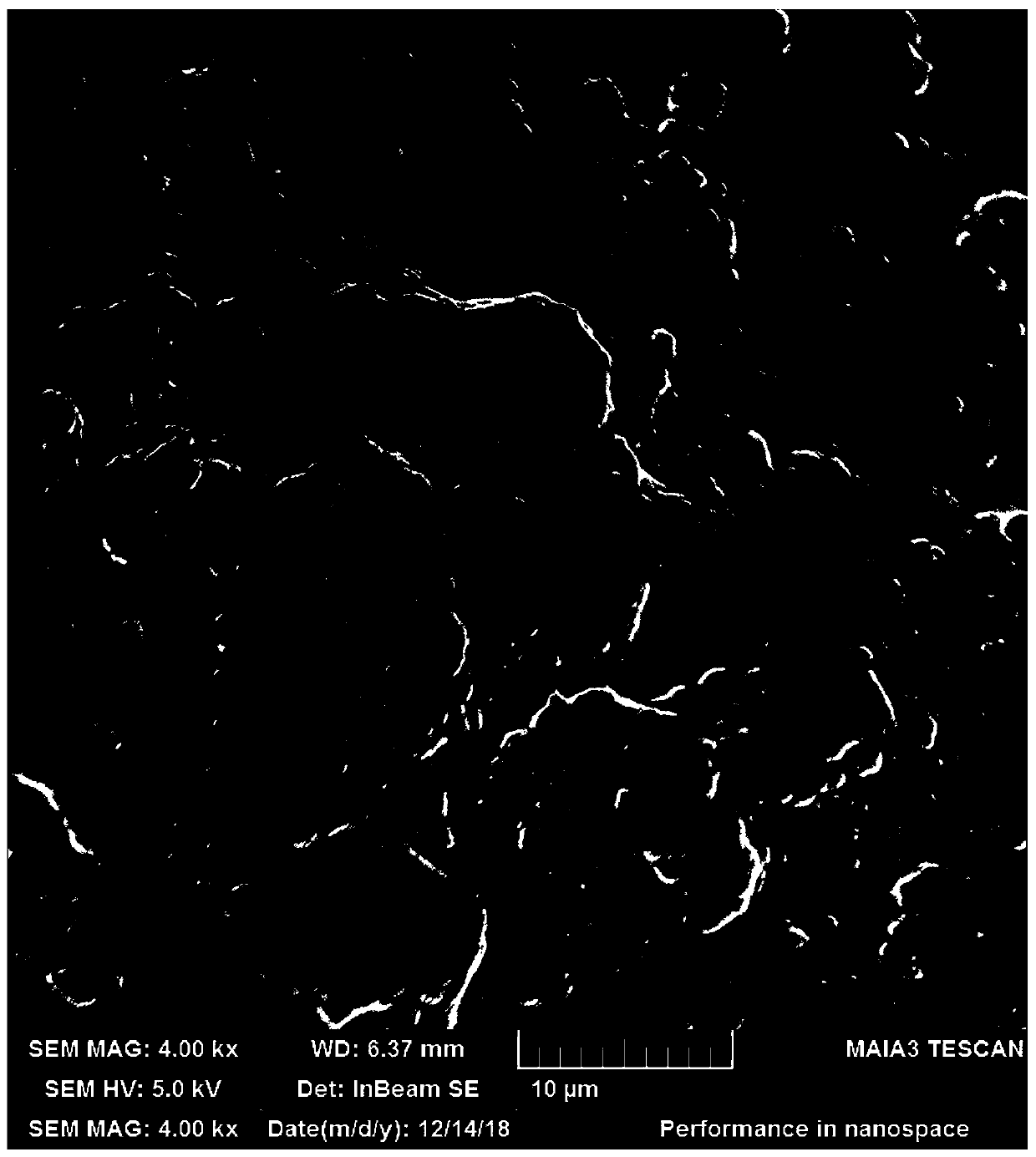

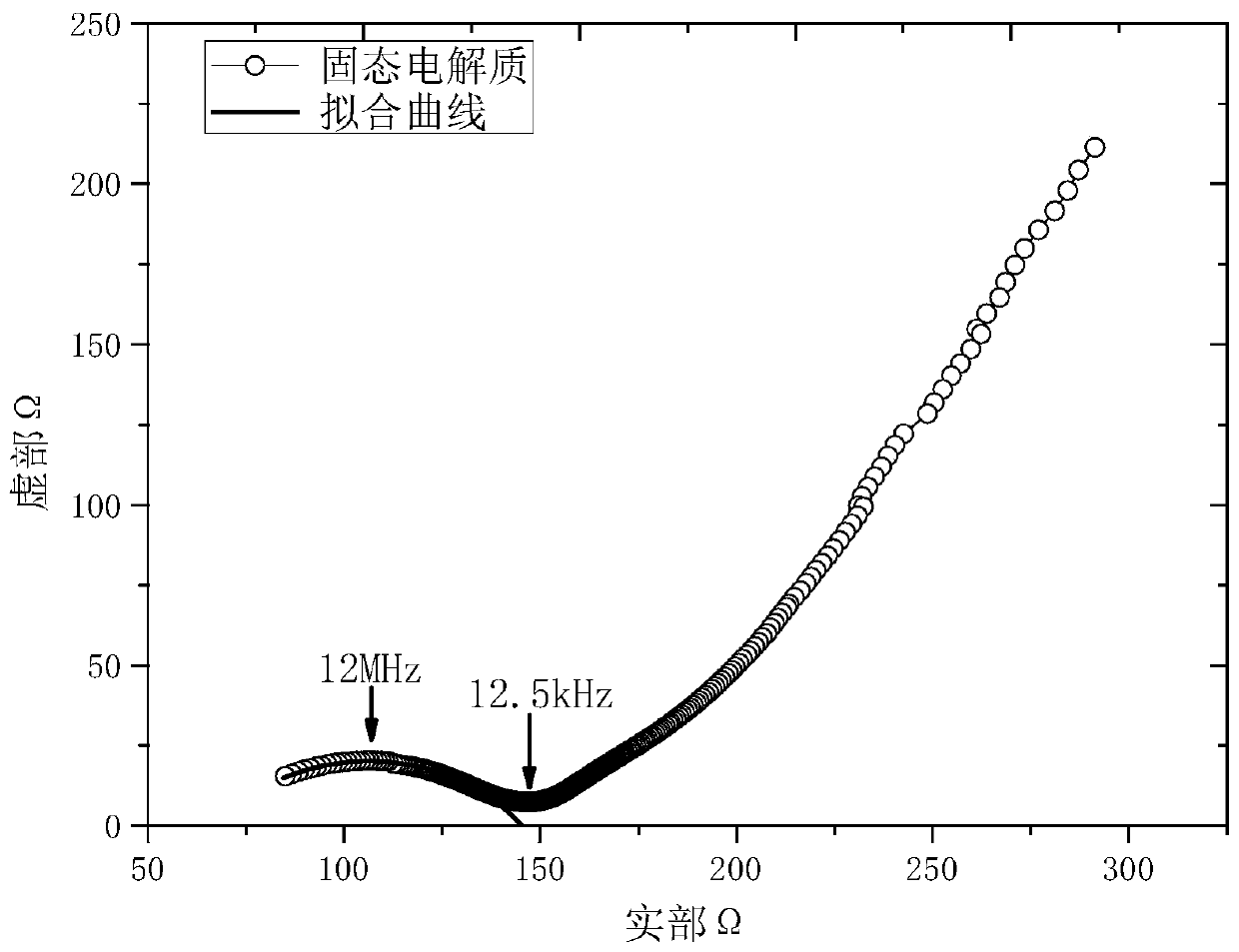

[0054] The sodium ion solid electrolyte of the present embodiment is characterized, and the results are as follows figure 2 As shown, after fitting, the impedance of the solid electrolyte of this embodiment is 148Ω, and the ion conductivity is 6.7×10 -4 S / cm. figure 1 It is a scanning electron microscope image of the solid electrolyte of this embodiment, which proves that its surface is relatively dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com