Method for preparing deep fermented feed containing two high-content organic acids

A production method and deep fermentation technology, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problem of high price, easy loss of L-malic acid, and ineffective guarantee of product quality stability To achieve stable product quality, improve the health level of the digestive tract, and reduce biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of monospore suspension: Take the inclined plane, add 6mL, 0.1mol / L, pH 6.0 phosphate buffer, scrape off the spores with an inoculation loop, shake the test tube, and immediately filter through a funnel with filter paper to obtain a monospore suspension , with a spore concentration of 10 6 individual / mL.

[0060] (1) Preparation of nitrosoguanidine solution

[0061] Weigh 2 mg with an analytical balance, add 2 mL of 0.1 mol / L, pH 6.0 phosphate buffer, add a little acetone appropriately to help dissolve nitrosoguanidine, and shake to dissolve in the dark.

[0062] (2) Mutagenesis treatment

[0063] Draw 1mL of nitrosoguanidine solution, add 1mL of spore suspension, shake at 30°C for 30min, immediately dilute 1000 times with cold normal saline to stop the action, and then dilute with 10 -2 、10 -3 、10 -4 Three dilutions were separated and cultured, and counted after 3 days at 30°C.

[0064] (3) Select the colony culture after the mutation according to the...

Embodiment 1

[0069] An embodiment of the deep fermented feed containing two kinds of high-content organic acids described in the present invention, the fermented feed described in this embodiment is prepared by the following method:

[0070] (1) Using the above-mentioned mutagenesis breeding method for Penicillium funiculosa to obtain a mutant strain with high yield of malic acid, which is fermented under ventilation and stirring conditions to obtain a Penicillium funiculum fermentation liquid;

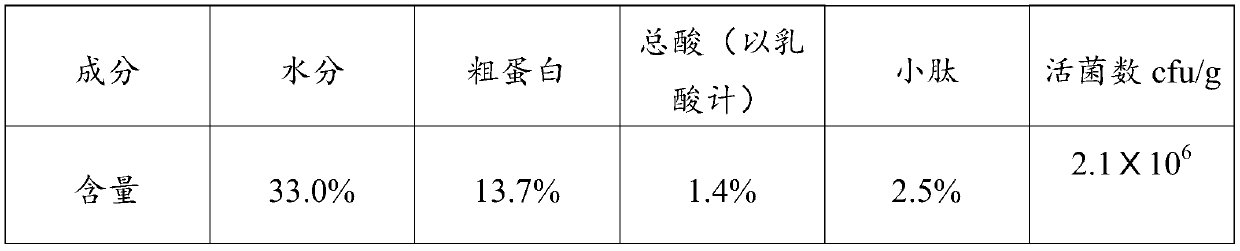

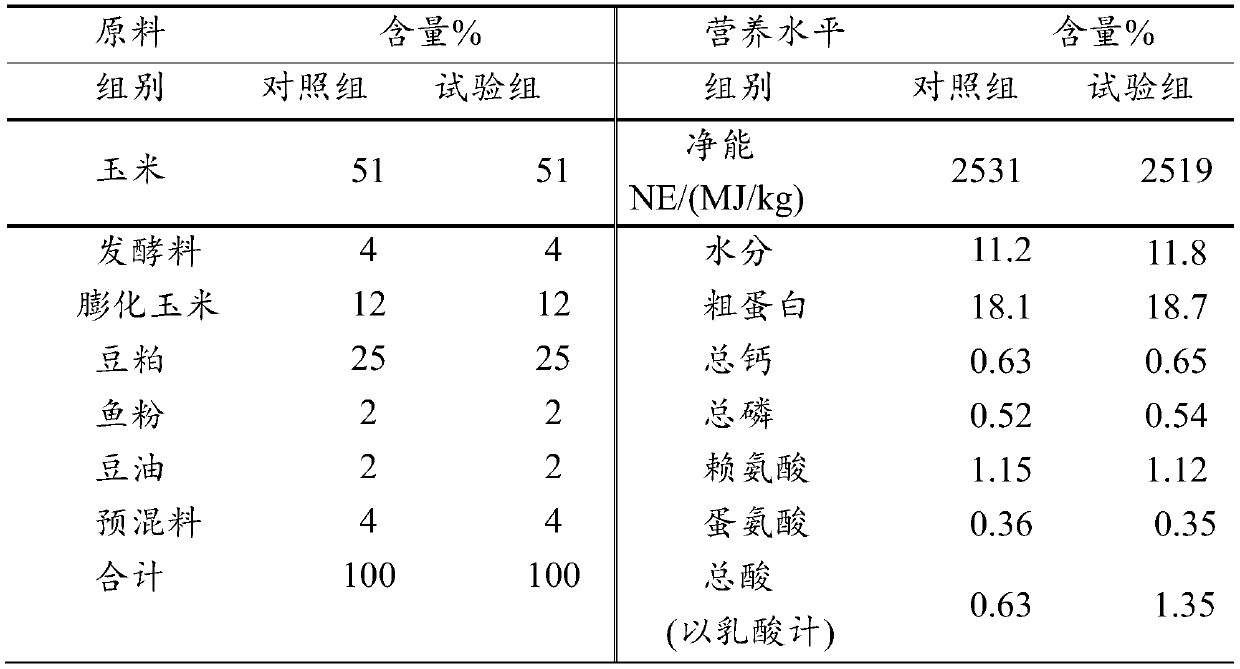

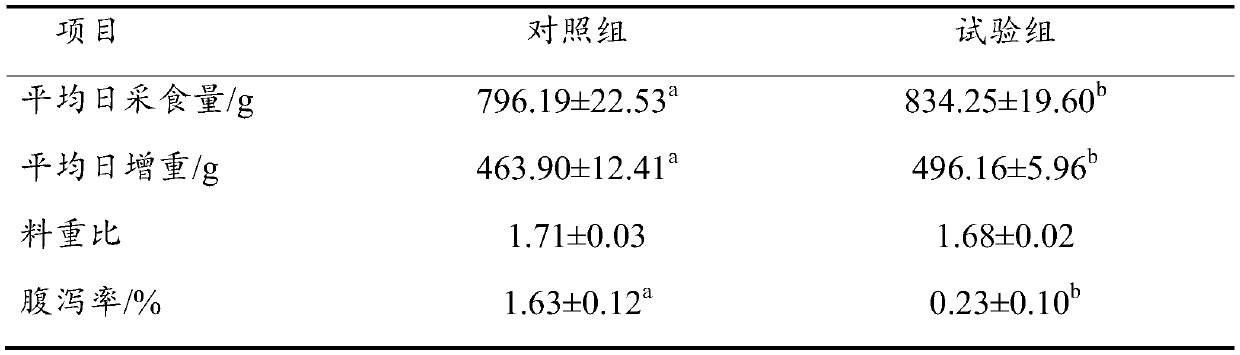

[0071] (2) The culture solution of Lactobacillus casei is mixed with the concentrated MRS medium of the same volume to form a lactic acid bacteria fermentation solution, which is then mixed with a certain volume of Penicillium fungus fermentation solution after fermentation for a certain period of time , continue to carry out static anaerobic fermentation in the tank, and obtain a mixed fermentation broth rich in L-malic acid and L-lactic acid and containing high concentration of lactic acid bacter...

Embodiment 2

[0076] An embodiment of the deep fermented feed containing two kinds of high-content organic acids described in the present invention, the fermented feed described in this embodiment is prepared by the following method:

[0077] (1) Using the above-mentioned mutagenesis breeding method for Penicillium funiculosa to obtain a mutant strain with high yield of malic acid, which is fermented under ventilation and stirring conditions to obtain a Penicillium funiculum fermentation liquid;

[0078] (2) The culture solution of Lactobacillus casei is mixed with the same volume of concentrated MRS medium to form a lactic acid bacteria fermentation solution, which is then mixed with the same volume of Penicillium fungus fermentation solution after fermentation for a certain period of time , continue to carry out static anaerobic fermentation in the tank, and obtain a mixed fermentation broth rich in L-malic acid and L-lactic acid and containing high concentration of lactic acid bacteria af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com