Preparation method of graphene-based photocatalytic material

A photocatalytic material and graphene-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low separation efficiency of photogenerated carriers, difficulties in meeting requirements, and poor photocatalytic efficiency and other problems, to achieve the effect of high crystallinity, easy operation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

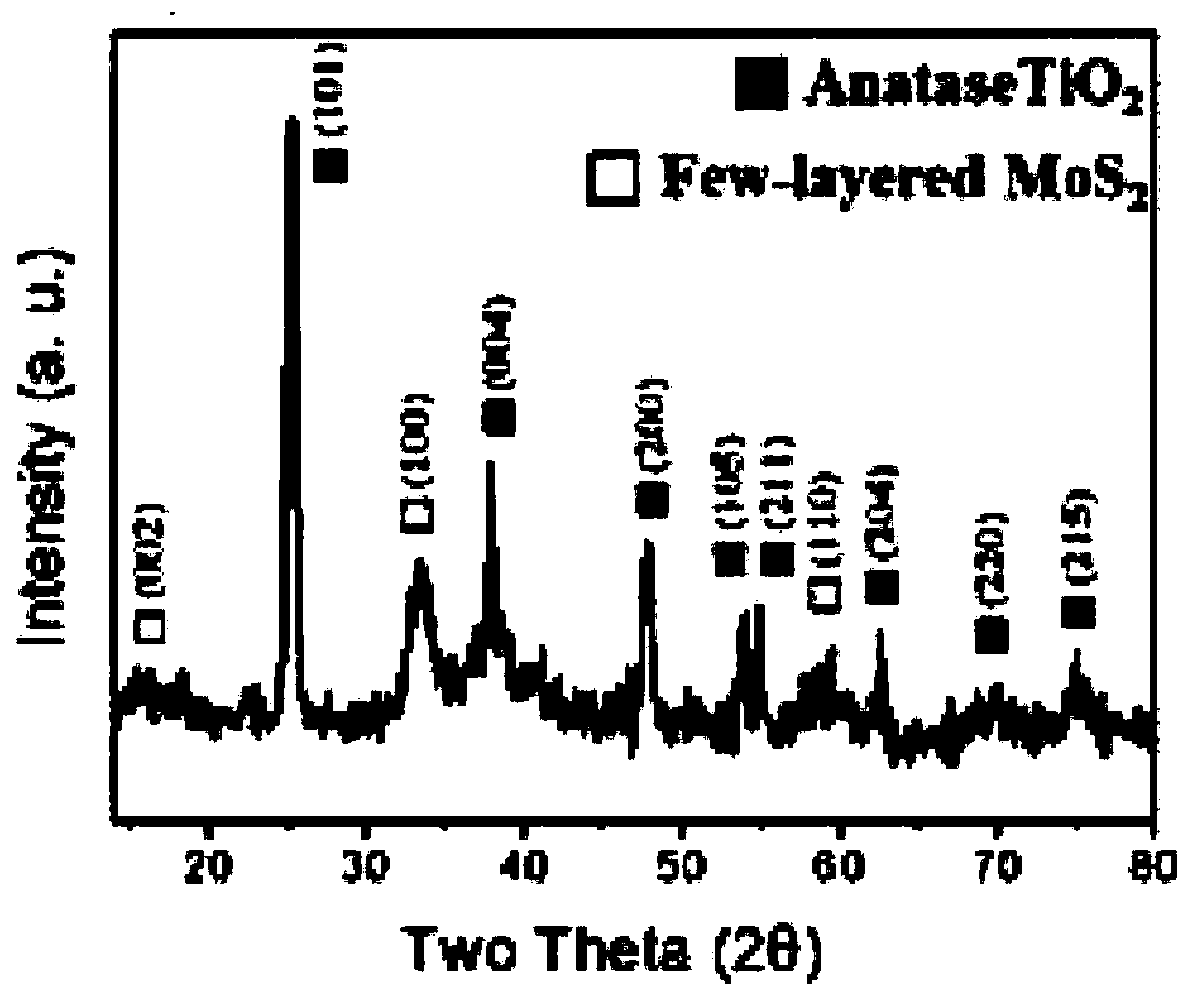

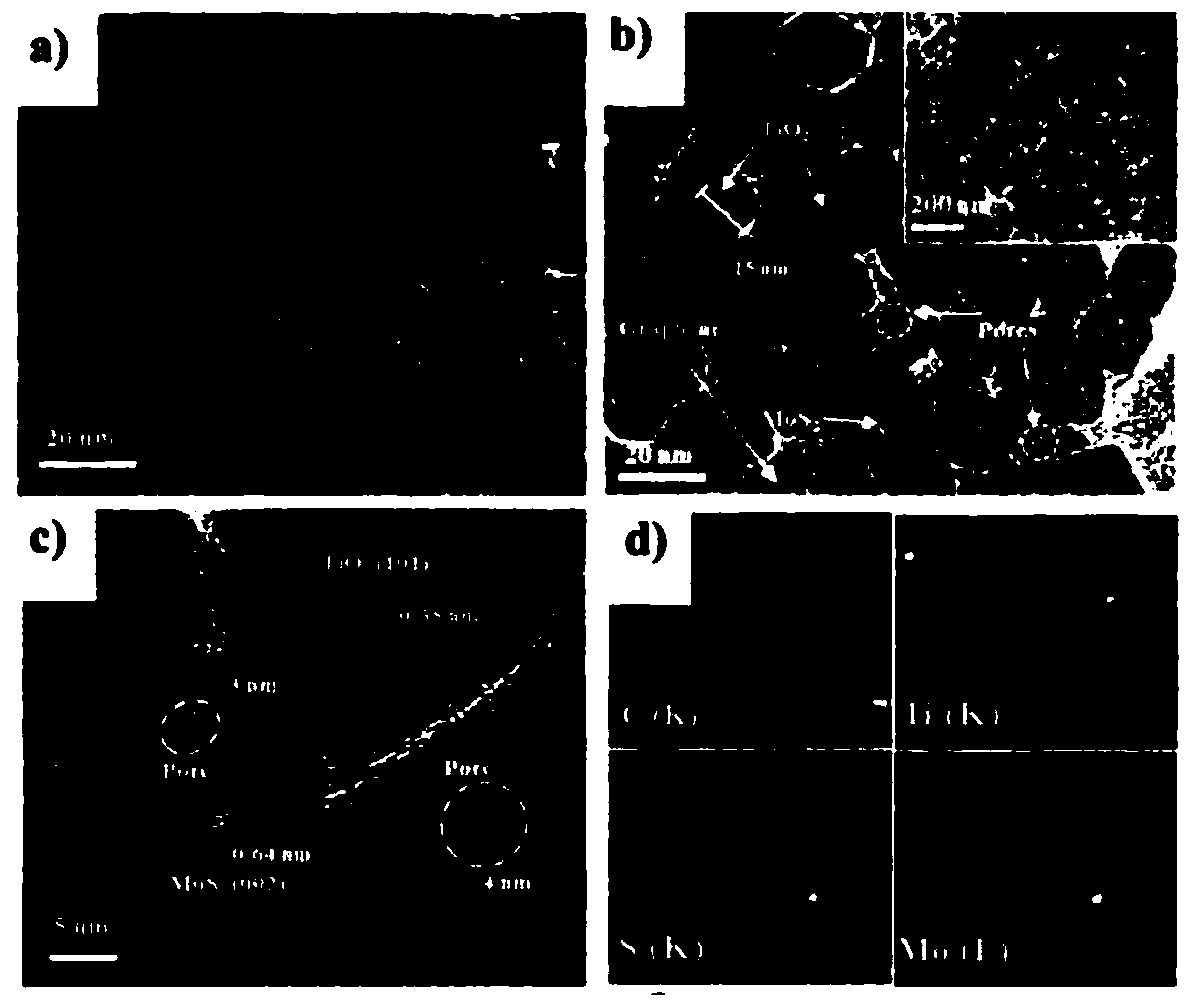

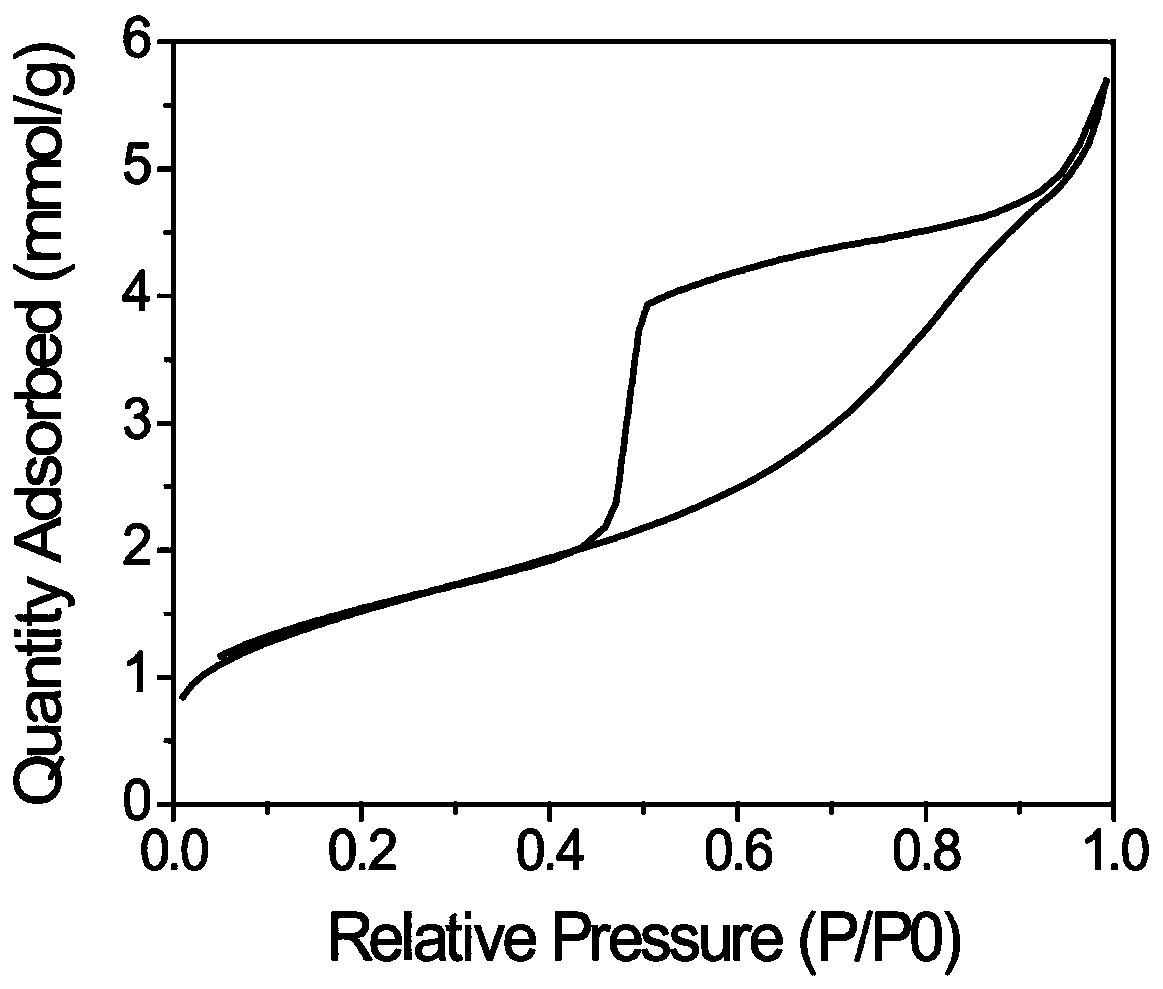

[0029] A preparation method of a graphene-based photocatalytic material, comprising the preparation of graphene oxide, the synthesis and catalyst crystallization of titanium dioxide / molybdenum disulfide / graphene composite hydrogel, comprising the following steps:

[0030] (1) Accurately weigh 1g of graphite powder, add it to an open glass beaker filled with 70mL of concentrated sulfuric acid, heat it in an oil bath at 35°C and keep it warm for 30min, keep magnetic stirring at a stirring speed of 60r / min;

[0031] (2) In the open glass beaker in step (1), add 3.5g potassium permanganate evenly in 10 times, keep the stirring speed of 60r / min, and stir for 4h;

[0032] (3) Transfer the open glass beaker in step (2) to an ice-water bath environment, add 200mL of deionized water and stir evenly, then add 20mL of hydrogen peroxide aqueous solution every 5min, adding 150mL of hydrogen peroxide aqueous solution in total, the process Keep magnetic stirring in the middle, the stirring s...

Embodiment 2

[0042] A preparation method of a graphene-based photocatalytic material, comprising the preparation of graphene oxide, the synthesis and catalyst crystallization of titanium dioxide / molybdenum disulfide / graphene composite hydrogel, comprising the following steps:

[0043](1) Accurately weigh 1g of graphite powder, add it to an open glass beaker filled with 50mL of concentrated sulfuric acid, heat it in an oil bath at 30°C and keep it warm for 30min, keep magnetic stirring, and the stirring speed is 60r / min;

[0044] (2) In the open glass beaker in step (1), add 3g potassium permanganate evenly in 5 times, keep the stirring speed of 60r / min, stir for 3h;

[0045] (3) Transfer the open glass beaker in step (2) to an ice-water bath environment, add 200mL of deionized water and stir evenly, then add 20mL of hydrogen peroxide aqueous solution every 3min, and add 120mL of hydrogen peroxide aqueous solution in total. Keep magnetic stirring in the middle, the stirring speed is 180r / mi...

Embodiment 3

[0055] A preparation method of a graphene-based photocatalytic material, comprising the preparation of graphene oxide, the synthesis and catalyst crystallization of titanium dioxide / molybdenum disulfide / graphene composite hydrogel, comprising the following steps:

[0056] (1) Accurately weigh 1g of graphite powder, add it to an open glass beaker filled with 100mL of concentrated sulfuric acid, heat it in an oil bath at 40°C and keep it warm for 30min, keep magnetic stirring, and the stirring speed is 120r / min;

[0057] (2) Add 5g potassium permanganate evenly in the open glass beaker in step (1) 10 times, keep the stirring speed of 120r / min, and stir for 5h;

[0058] (3) Transfer the open glass beaker in step (2) to an ice-water bath environment, add 200mL of deionized water and stir evenly, then add 20mL of hydrogen peroxide aqueous solution every 5min, and add 200mL of hydrogen peroxide aqueous solution in total. Keep magnetic stirring in the middle, the stirring speed is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com