Preparation method and application of carbon nitride supported chromium monoatom Fenton catalyst

A technology of carbon nitride and catalyst, which is applied in the field of preparation of carbon nitride-supported chromium single-atom Fenton catalyst, can solve the problems of high recombination rate limiting practical application, etc., and achieve high yield, mild reaction conditions, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step S1: Put substance A in a conical flask with a lid and ultrasonically mix it evenly and keep stirring for 4 hours. The obtained solid is washed and dried in vacuum at 60°C overnight, and then ground into powder to obtain g-C 3 N 4 A polymer, said substance A consisting of xanthine, melamine and cyanuric acid;

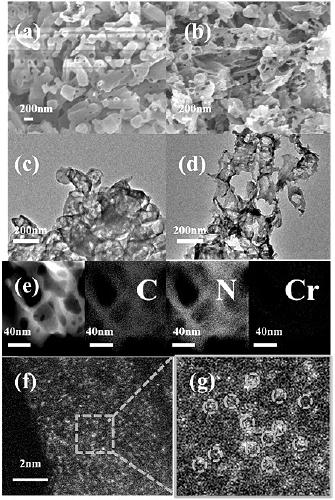

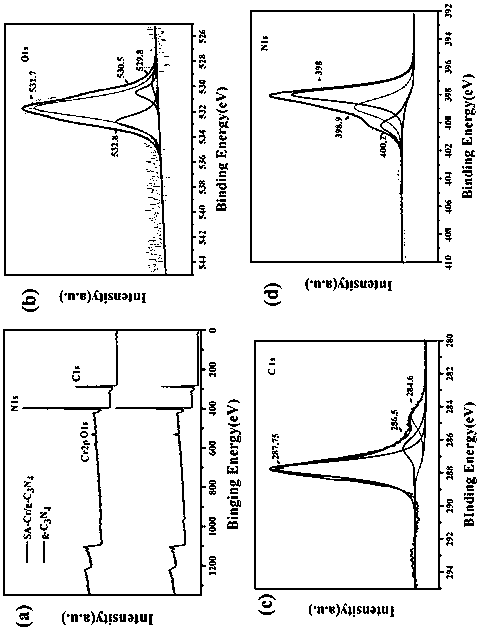

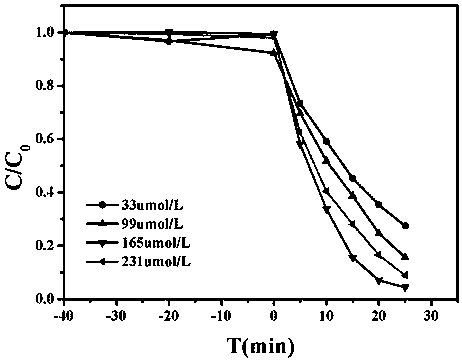

[0022] Step S2: Dissolving chromium nitrate in water and ultrasonically dispersing to obtain a chromium nitrate solution, and then adding the chromium nitrate solution to the g-C obtained in step S1 3 N 4 In the polymer, stir and mix evenly, filter and vacuum dry at 60°C for 12 hours, grind the product into powder, and then heat the obtained powder to 550°C for 2 hours under inert gas at a heating rate of 5°C / min to obtain the target product nitrogen Carbon nitride-supported chromium single-atom Fenton catalyst (SA-Cr / g-C3N4), based on theoretical calculations, the mass fraction of chromium atoms in the carbon nitride-supported chromium single-atom Fenton c...

Embodiment 2

[0026]Step S1: Put substance A in a conical flask with a lid and mix it homogeneously by ultrasonic and keep stirring for 6h. The obtained solid is washed and dried in vacuum at 60°C overnight, and then ground into powder to obtain g-C 3 N 4 A polymer, said substance A consisting of xanthine, melamine and cyanuric acid;

[0027] Step S2: Dissolving chromium nitrate in water and ultrasonically dispersing to obtain a chromium nitrate solution, and then adding the chromium nitrate solution to the g-C obtained in step S1 3 N 4 In the polymer, stir and mix evenly, filter and vacuum dry at 60°C for 12 hours, grind the product into powder, and then heat the obtained powder to 550°C for 2 hours under inert gas at a heating rate of 5°C / min to obtain the target product nitrogen Carbon nitride-supported chromium single-atom Fenton catalyst, based on theoretical calculations, the mass fraction of chromium atoms in the carbon nitride-supported chromium single-atom Fenton catalyst is 4%. ...

Embodiment 3

[0029] Step S1: Put substance A in a conical flask with a lid and ultrasonically mix it evenly and keep stirring for 4 hours. The obtained solid is washed and dried in vacuum at 60°C overnight, and then ground into powder to obtain g-C 3 N 4 A polymer, said substance A consisting of xanthine, melamine and cyanuric acid;

[0030] Step S2: Dissolving chromium nitrate in water and ultrasonically dispersing to obtain a chromium nitrate solution, and then adding the chromium nitrate solution to the g-C obtained in step S1 3 N 4 In the polymer, stir and mix evenly, filter and vacuum dry at 100°C for 12 hours, grind the product into powder, and then heat the obtained powder to 550°C at a heating rate of 5°C / min and calcinate for 2 hours under inert gas to obtain the target product nitrogen Carbon nitride-supported chromium single-atom Fenton catalyst, based on theoretical calculations, the mass fraction of chromium atoms in the carbon nitride-supported chromium single-atom Fenton c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com