Preparation method for electronic-grade n-propyl propionate

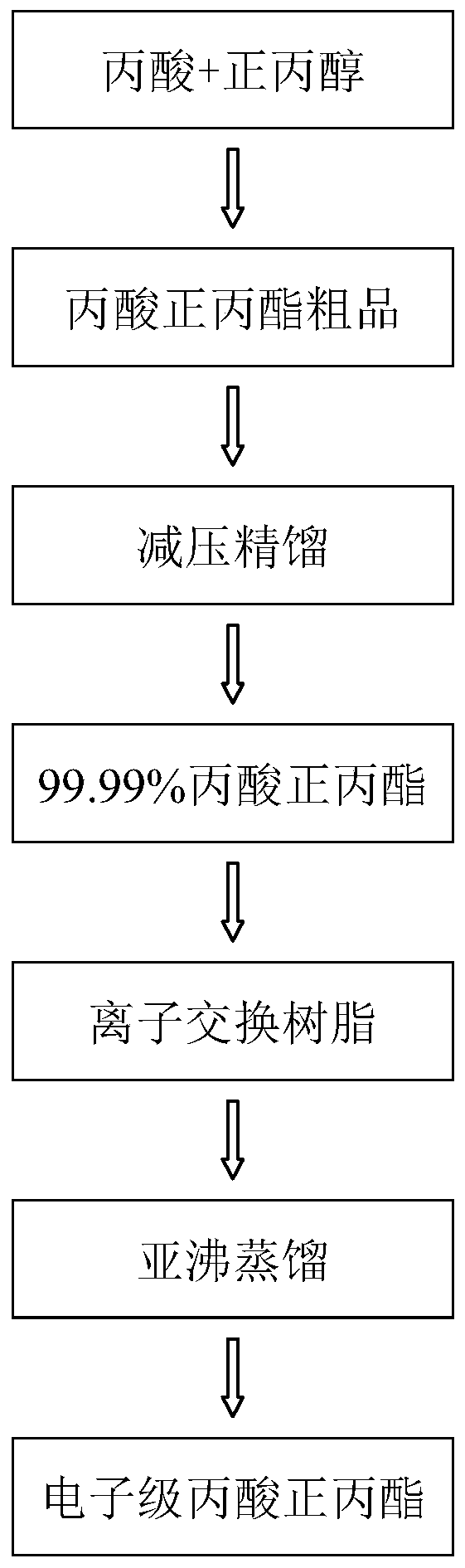

An electronic-grade n-propyl propionate technology, which is applied in the field of preparation of electronic-grade n-propyl propionate, can solve the problems of slow progress in n-propyl propionate research, unrecorded metal ion content, and expensive catalysts, etc., reaching Reduce re-investment costs, facilitate rectification and purification, and facilitate product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The synthesis of embodiment 1 n-propyl propionate crude product

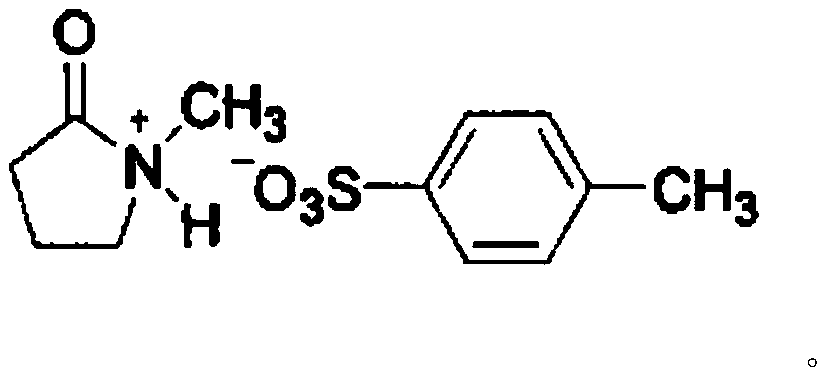

[0029] 1.1 Catalyst synthesis

[0030] Feed according to the molar ratio of N-methyl-2-pyrrolidone and p-toluenesulfonic acid 1:1~1.5:1, stir and react at 60°C~120°C for 4h, then filter the reaction solution, add ethyl acetate to wash the solid, and The obtained white solid was dried to obtain the ionic liquid [HNMP]PTSA (N-methyl-2-pyrrolidone p-toluenesulfonate). The improved ionic liquid [HNMP] PTSA catalyst is insoluble in propionic acid and propanol at the beginning of the esterification reaction, and starts to dissolve in the reaction liquid after the heating reaction and undergoes a homogeneous reaction. After the reaction is completed, it is cooled to room temperature, and the catalyst Precipitated in solid form. Different from the p-toluenesulfonic acid catalytic esterification process, it is always dissolved in the reaction solution and cannot be recycled, which affects the subsequent sepa...

Embodiment 2

[0041] The preparation of embodiment 2 purity greater than or equal to 99.99 n-propyl propionate

[0042] 2.1 Synthesis of Propyl Propionate Crude Product

[0043] Weigh 740.8g of propionic acid and 901.5g of propanol in a 3L reaction flask, then add 111.12g of ionic liquid [HNMP]PTSA catalyst and 200mL of water-carrying agent cyclohexane, heat and reflux to separate water, take samples for analysis, and test the conversion After the yield reached more than 99%, the reaction was stopped, and after the esterification liquid was cooled to room temperature, the solid (catalyst) was filtered off to obtain the crude product of n-propyl propionate.

[0044] 2.2 Vacuum distillation

[0045]The n-propyl propionate crude product is added in the rectification tower to carry out rectification under vacuum. The height of the rectification tower is 1.3m, and the inner diameter of the tower is 32mm. The number of plates was 42.

[0046] In this example, the temperature at the botto...

Embodiment 3

[0058] The preparation of embodiment 3 electronic grade n-propyl propionate

[0059] 3.1 Synthesis of Propyl Propionate

[0060] Weigh 740.8g of propionic acid and 901.5g of propanol into a 3L reaction flask, then add 111.12g of ionic liquid [HNMP]PTSA catalyst and 200mL of water-carrying agent cyclohexane, heat and reflux at 100°C for 8 hours to separate water, and take samples for analysis. It is tested that the conversion rate reaches more than 99%, and the reaction is stopped. After the esterification liquid is cooled to room temperature, the solid (catalyst) is filtered off to obtain the crude product of n-propyl propionate.

[0061] 3.2 Vacuum distillation

[0062] The n-propyl propionate crude product is added in the rectification tower to carry out rectification under vacuum. The height of the rectification tower is 1.3m, and the inner diameter of the tower is 32mm. The number of plates was 42. The bottom temperature of the rectification tower is 50°C, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com