Sodium polyacrylate high-absorbent resin with high blood-sucking property and preparation method thereof

A sodium polyacrylate and high absorbency technology, applied in the field of high absorbency resins, can solve the problems of inability to absorb blood, large volume, etc., and achieve the effects of good compatibility, solving adsorption problems, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

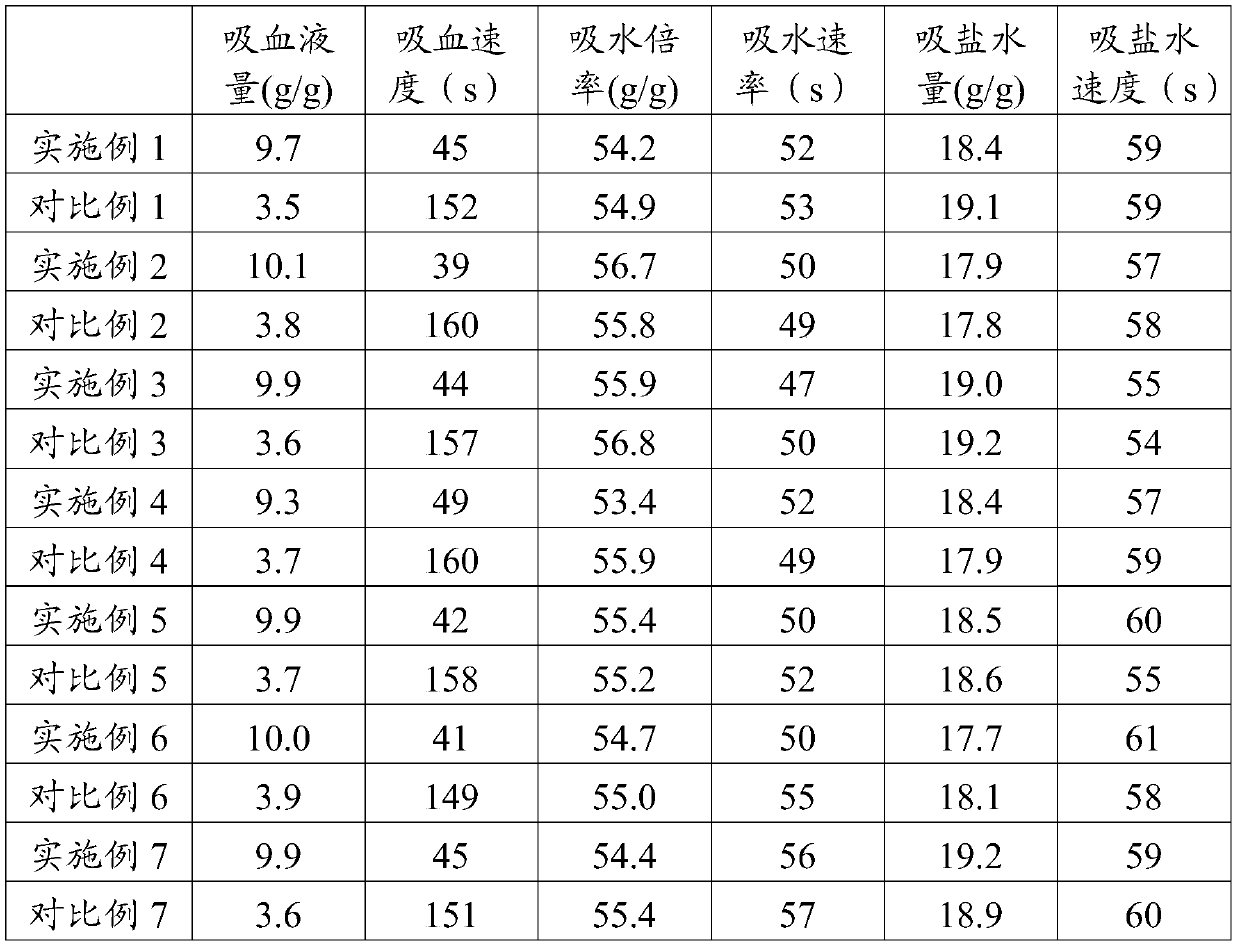

Embodiment 1

[0043] Weigh 180kg of sodium hydroxide, make it into a 30% aqueous solution, and let it cool down; add 360kg of acrylic acid, 20kg of N-glycine-based acrylamide and 100kg of deionized water into the neutralization tank, stir and dissolve evenly, then add the hydrogen prepared above dropwise Sodium oxide aqueous solution, control the temperature of the neutralization tank to be lower than 50°C, after the dropwise addition, stir and react for 20-30 minutes.

[0044] Weigh 4.4kg of ammonium persulfate, 2.2kg of sodium sulfite and 6kg of diacetone acrylamide, dissolve them in 25kg of deionized water and add them to a polymerization kettle, and add the neutralization solution of acrylic acid and its functional monomer N-glycine-based acrylamide obtained above, Polymerize at 20-60°C for 15 minutes to obtain soft colloid of superabsorbent resin.

[0045] Dry the obtained soft colloid at 100°C-180°C for 50-120min, and crush it into granular materials.

Embodiment 2

[0049] Weigh 200kg of sodium hydroxide, make it into a 30% aqueous solution, and let it cool down; add 380kg of acrylic acid, 18kg of N-glutamic acid acrylamide and 80kg of deionized water into the neutralization tank, stir and dissolve evenly, then add dropwise the above preparation Aqueous sodium hydroxide solution, the temperature of the neutralization tank is controlled to be lower than 50°C, after the dropwise addition is completed, the reaction is stirred for 20-30min.

[0050] Weigh 4.8kg of ammonium persulfate, 2.4kg of sodium sulfite and 6.2kg of diacetone acrylamide, dissolve them in 28kg of deionized water and add them to the polymerization kettle, and neutralize the acrylic acid and its functional monomer N-glutamic acid acrylamide obtained above Liquid is added, and polymerized at 20-60°C for 15 minutes to obtain a soft colloid of superabsorbent resin.

[0051] Dry the obtained soft colloid at 100°C-180°C for 50-120min, and crush it into granular materials.

Embodiment 3

[0055]Weigh 180kg of sodium hydroxide, make it into a 30% aqueous solution, and let it cool down; add 350kg of acrylic acid, 15kg of N-lysine-acrylamide and 100kg of deionized water into the neutralization tank, stir and dissolve evenly, and then dropwise add the above preparation Aqueous sodium hydroxide solution, the temperature of the neutralization tank is controlled to be lower than 50°C, after the dropwise addition is completed, the reaction is stirred for 20-30min.

[0056] Weigh 4.5kg of ammonium persulfate, 2.3kg of sodium sulfite and 6kg of polyethylene glycol diacrylate, dissolve them in 25kg of deionized water and add them to a polymerization kettle, and add the acrylic acid and its functional monomer N-lysine-based acrylamide obtained above to The neutralizing solution is added, and the polymerization reaction is carried out at 20-60° C. for 15 minutes to obtain a soft colloid of superabsorbent resin.

[0057] Dry the obtained soft colloid at 100°C-180°C for 50-12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com