Method and system for in-situ coating of electrospinning nanofiber film on surface of material

An in-situ coating and nanofiber technology, which is applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve the problems of high interface contact resistance, cumbersome assembly, poor nano-interface structure performance, etc., to reduce the interface Effects of contact resistance, reduction of assembly cost, and improvement of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this embodiment, the CNT (carbon nanotube) fiber material is taken as an example, and the electrospun PAN (polyacrylonitrile) nanofiber film is coated on its surface in situ, and the specific steps are as follows:

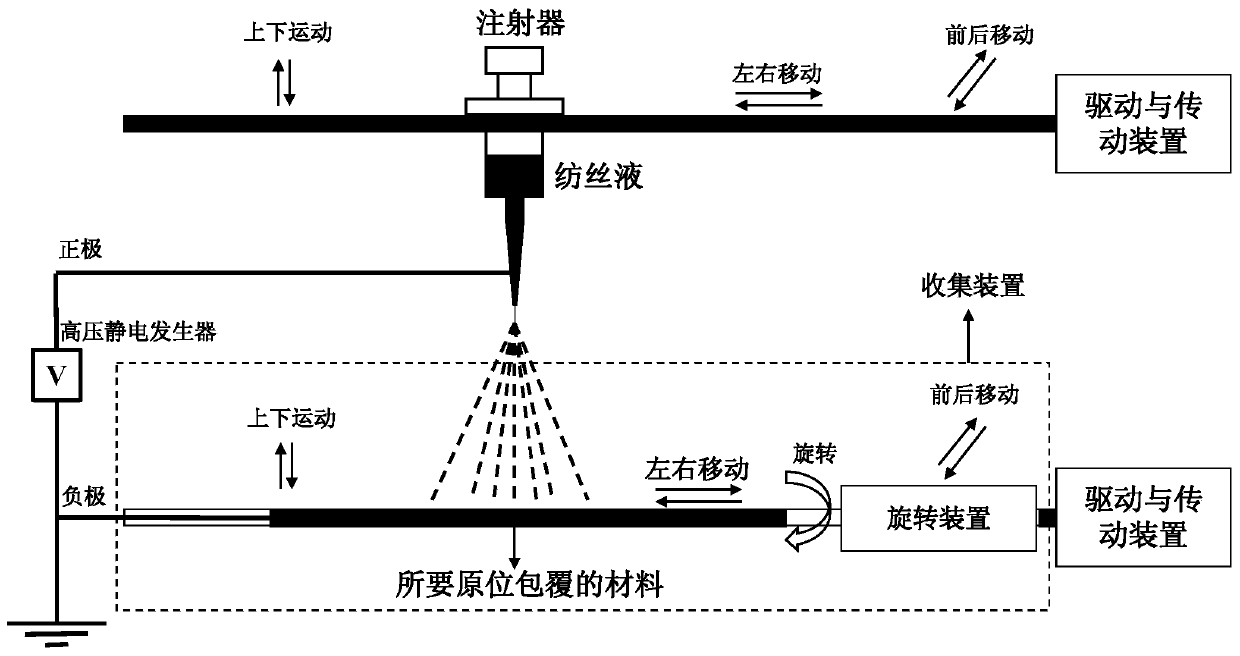

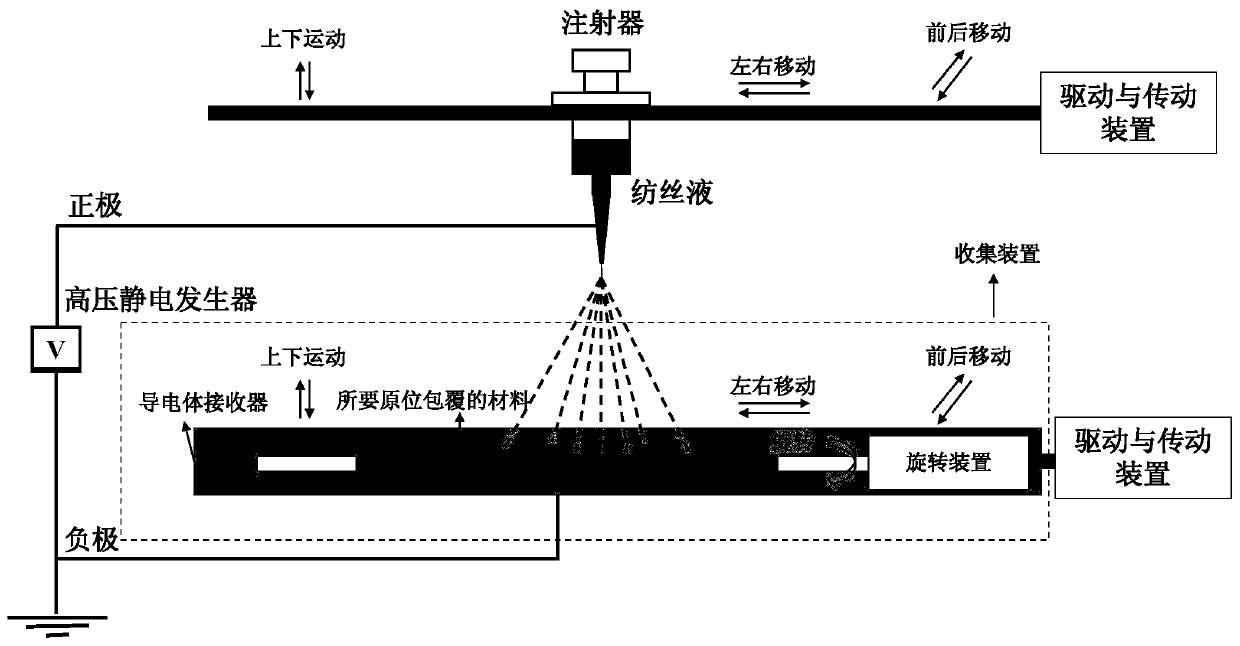

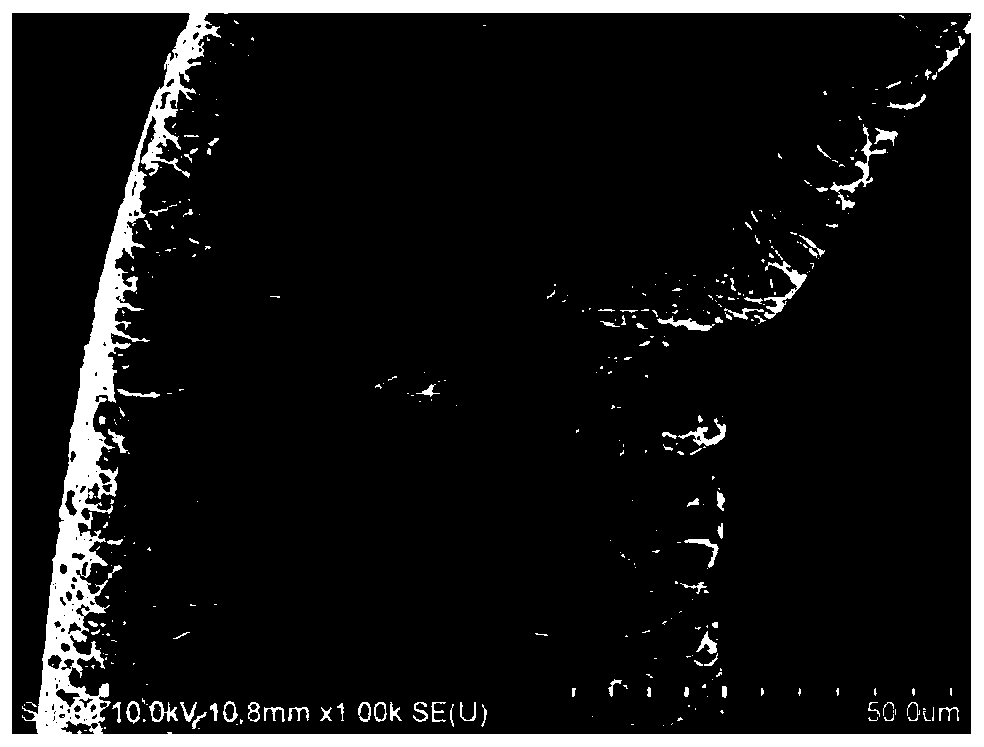

[0070] Because CNT (carbon nanotube) fiber material conductivity is better, so present embodiment adopts figure 1 In this system, the CNT fiber material is the receiver, which is connected to the negative electrode of the high-voltage electrostatic generator, installed on the rotating device in the collection device, and the electrospinning distance is adjusted to 100mm. The electrospinning solution is made of the precursor PAN (polyacrylonitrile) and the solvent DMF (N,N-dimethylformamide) according to the ratio of 5%. During the electrospinning process, the electrospinning voltage is 15.0kV, Control the diameter of the syringe needle (one) to be 0.15mm, the relative left and right moving speed of the syringe and the collection device to be 50mm / s, and t...

Embodiment 2

[0073] In this embodiment, the CNT (carbon nanotube) fiber material is taken as an example, and the electrospun PAN (polyacrylonitrile) nanofiber film is coated on its surface in situ, and the specific steps are as follows:

[0074] Because CNT (carbon nanotube) fiber material conductivity is better, so present embodiment adopts figure 1 The system, the CNT fiber material is the receiver, which is connected to the negative pole of the high-voltage electrostatic generator, installed on the rotating device in the collection device, and the electrospinning distance is adjusted to 50mm. The electrospinning solution is made from the precursor PAN (polyacrylonitrile) and the solvent DMF (N,N-dimethylformamide) according to the ratio of 5%. During the electrospinning process, the electrospinning voltage is 10.0kV, The spinning rate is 500μL / h, the diameter of the syringe needle (one) is controlled to be 0.15mm, the relative left and right moving speed of the syringe and the collectin...

Embodiment 3

[0076] In this embodiment, the CNT (carbon nanotube) fiber material is taken as an example, and the electrospun PAN (polyacrylonitrile) nanofiber film is coated on its surface in situ, and the specific steps are as follows:

[0077] Because CNT (carbon nanotube) fiber material conductivity is better, so present embodiment adopts figure 1 The system, the CNT fiber material is the receiver, which is connected to the negative pole of the high-voltage electrostatic generator, installed on the rotating device in the collection device, and the electrospinning distance is adjusted to 150mm. The electrospinning liquid is made from the precursor PAN (polyacrylonitrile) and the solvent DMF (N,N-dimethylformamide) according to the ratio of 5%. During the electrospinning process, the electrospinning voltage is 36.0kV, The spinning rate is 800μL / h, the diameter of the syringe needle (one) is controlled to be 0.10mm, the relative left and right moving speed of the syringe and the collecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com