Activated dye ink suitable for ultra-high-speed digital printing and preparation method thereof

A reactive dye, digital printing technology, applied in dyeing, textile and papermaking, etc., can solve the problems affecting the popularization and development of the digital printing industry, and achieve the effects of excellent moisture retention, good storage stability, and increased dye content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

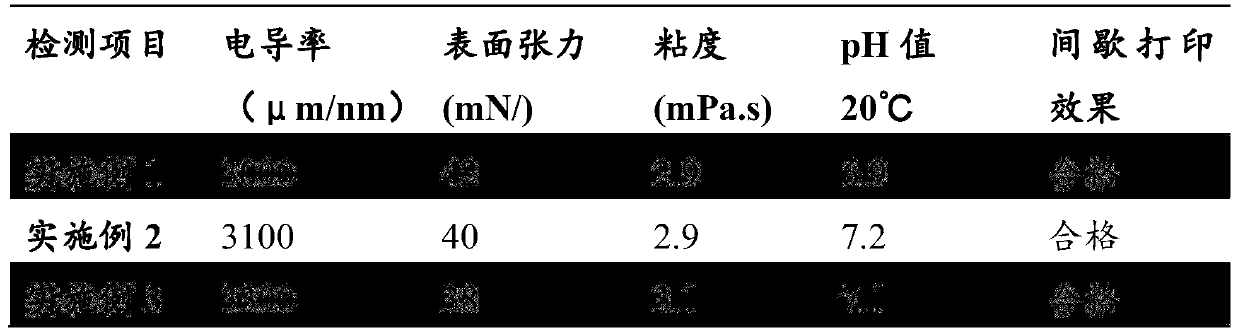

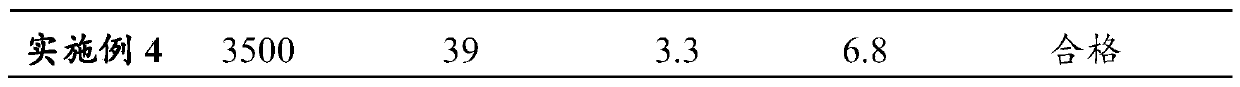

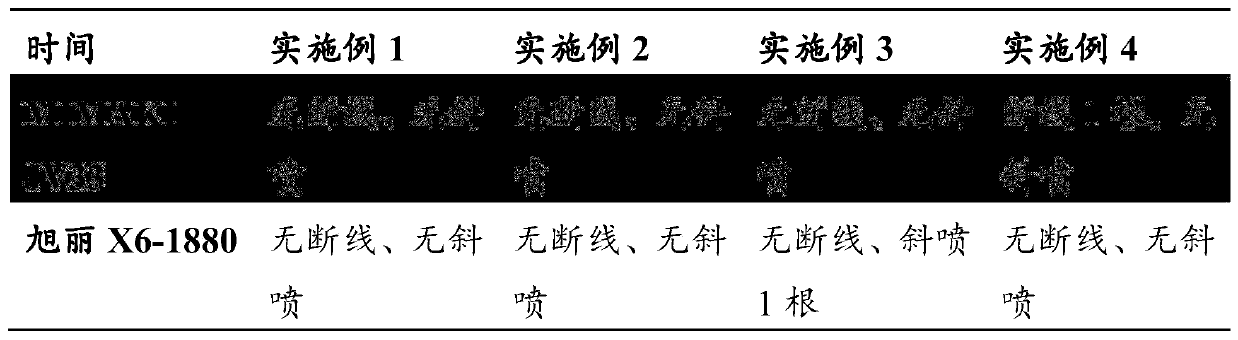

Examples

Embodiment 1

[0028] The preparation method of S1, polyethylene-benzyl acrylate dispersant specifically comprises the steps:

[0029] 1) 5 parts of styrene, 40 parts of benzyl acrylate, and 6 parts of triethyltetramine are configured into an aqueous solution of equal concentration;

[0030] 2) Add the three aqueous solutions into a three-necked flask equipped with a stirring device and a condensation reflux device, and add a certain amount of potassium persulfate and mercaptoacetic acid, heat up to 80°C, and react for 4 hours;

[0031] 3) Adjust the pH value to 8 with an appropriate amount of sodium hydroxide solution to obtain a white water-soluble emulsion, and cool it to room temperature to obtain a dispersant.

[0032] S2. A reactive dye ink suitable for ultra-high-speed digital printing, which consists of the following components by mass percentage, including the following raw material components: C.I. reactive red 141 17%, polymer dispersant prepared in step S1 1%, EH -36%, nonylphen...

Embodiment 2

[0035] The preparation method of S1, polyethylene-benzyl acrylate dispersant specifically comprises the steps:

[0036] 1) 10 parts of styrene, 40 parts of benzyl acrylate, and 10 parts of triethylenetetramine are configured into an aqueous solution of equal concentration;

[0037] 2) Add the three aqueous solutions into a three-necked flask equipped with a stirring device and a condensation reflux device, and add a certain amount of potassium persulfate and mercaptoacetic acid, heat up to 100°C, and react for 5 hours;

[0038] 3) Adjust the pH value to 8 with an appropriate amount of sodium hydroxide solution to obtain a white water-soluble emulsion, and cool it to room temperature to obtain a dispersant.

[0039] S2. A reactive dye ink suitable for ultra-high-speed digital printing, which consists of the following components by mass percentage, including the following raw material components: C.I. reactive red 245 19%, polymer dispersant prepared in step S1 2%, BYK -3484%, ...

Embodiment 3

[0042]The preparation method of S1, polyethylene-benzyl acrylate dispersant specifically comprises the steps:

[0043] 1) 10 parts of styrene, 30 parts of benzyl acrylate, and 7 parts of triethylenetetramine are configured into an aqueous solution of equal concentration;

[0044] 2) Add the three aqueous solutions into a three-necked flask equipped with a stirring device and a condensation reflux device, and add a certain amount of potassium persulfate and mercaptoacetic acid, heat up to 100°C, and react for 5 hours;

[0045] 3) Adjust the pH value to 8 with an appropriate amount of sodium hydroxide solution to obtain a white water-soluble emulsion, and cool it to room temperature to obtain a dispersant.

[0046] S2, a reactive dye ink suitable for ultra-high-speed digital printing, which consists of the following components by mass percentage, including the following raw material components: C.I. reactive brown 22%, polymer dispersant prepared in step S1 4%, EH- 6-6%, nonylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com