Extraction process of tea bran

An extraction process and technology of tea bran, applied in the field of extraction of plant active ingredients, can solve the problem of low extraction efficiency, and achieve the effects of increasing extraction efficiency, promoting flocculation and sedimentation, and improving extraction efficiency and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

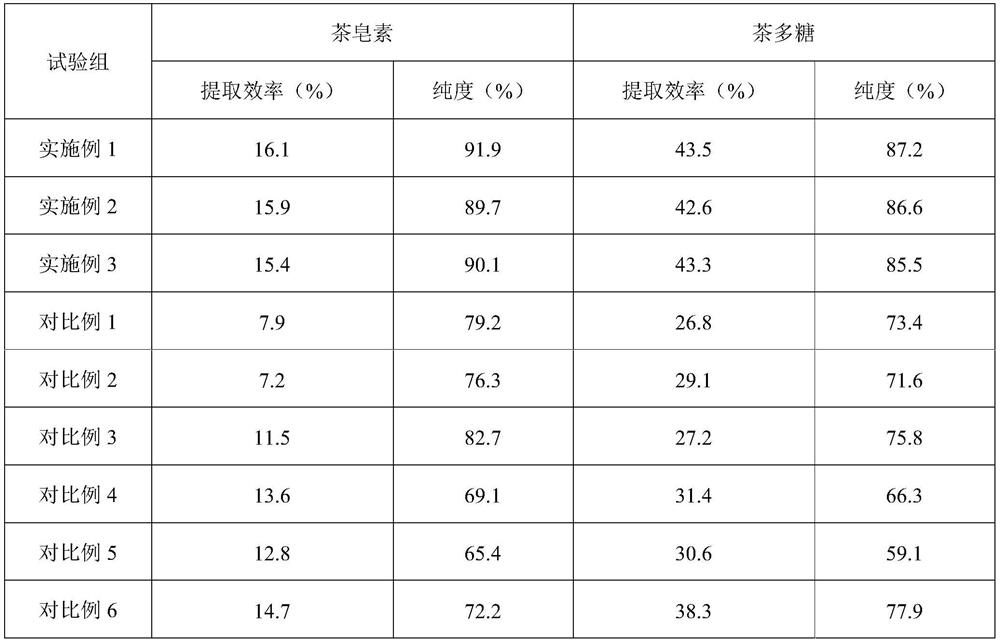

Examples

Embodiment 1

[0039] A process for extracting tea bran, comprising the following steps:

[0040] (1) tea bran is obtained by oil-pressing tea seeds, and tea bran powder is obtained by pulverizing the tea bran;

[0041] (2) Disperse 300g of tea bran powder with water, use 0.3% cellulase (enzyme activity of 20000U / g) and 0.03% pectinase (enzyme activity of 25000U / g) to enzymolyze, filter, add to the filtrate 0.6% mass (based on the mass of tea bran powder) of extractant (a mixture of sodium carbonate and sodium salicylate with a mass ratio of 3:1), centrifuged to obtain supernatant 1 and precipitate 1;

[0042] (3) adding the precipitate 1 to 6 times the mass of 70% ethanol aqueous solution for leaching, and centrifuging to obtain supernatant 2 and precipitate 2;

[0043] (4) After supernatant 1 and supernatant 2 are mixed, add 0.3% (in terms of tea bran powder mass) of precipitant (mass ratio is 2:1 mixture of sodium alginate and chitosan, wherein, the Described sodium alginate is added wi...

Embodiment 2

[0047] A process for extracting tea bran, comprising the following steps:

[0048] (1) tea bran is obtained by oil-pressing tea seeds, and tea bran powder is obtained by pulverizing the tea bran;

[0049] (2) Disperse 300g of tea bran powder with water, use 0.1% cellulase (enzyme activity of 25000U / g) and 0.05% pectinase (enzyme activity of 50000U / g) to enzymolyze, filter, add to the filtrate 1% mass (based on the mass of tea bran powder) of extractant (a mixture of sodium carbonate and sodium salicylate with a mass ratio of 1:1), centrifuged to obtain supernatant 1 and precipitate 1;

[0050](3) adding the precipitate 1 to 10 times the mass of 60% ethanol aqueous solution for leaching, and centrifuging to obtain supernatant 2 and precipitate 2;

[0051] (4) After supernatant 1 and supernatant 2 are mixed, add 0.5% (in terms of tea bran powder mass) of precipitant (mass ratio is 1:1 mixture of sodium alginate and chitosan, wherein, the Described sodium alginate is added with...

Embodiment 3

[0055] A process for extracting tea bran, comprising the following steps:

[0056] (1) tea bran is obtained by oil-pressing tea seeds, and tea bran powder is obtained by pulverizing the tea bran;

[0057] (2) Disperse 300g of tea bran powder with water, use 0.5% cellulase (enzyme activity is 50000U / g) and 0.01% pectinase (enzyme activity is 20000U / g) after enzymolysis, filter, add to the filtrate 0.5% mass (based on the mass of tea bran powder) of extractant (a mixture of sodium carbonate and sodium salicylate with a mass ratio of 5:1), centrifuged to obtain supernatant 1 and precipitate 1;

[0058] (3) adding the precipitate 1 to 5 times the mass of 75% ethanol aqueous solution for leaching, and centrifuging to obtain supernatant 2 and precipitate 2;

[0059] (4) After the supernatant 1 and the supernatant 2 are mixed, add 0.2% (in terms of tea bran powder mass) of a precipitant (mass ratio is a mixture of sodium alginate and chitosan at 3:1, wherein the Described sodium al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com