Method for preparing Jerusalem artichoke inulin by joint use of ultrasonic assistance and microbial fermentation methods

A microbial fermentation method, the technology of Jerusalem artichoke inulin, which is applied in the directions of food ultrasonic treatment, food science, yeast-containing food ingredients, etc., can solve the problems of increased production cost of inulin, low extraction efficiency, and difficult to overcome the key technical barriers of inulin processing. , to avoid the reduction of the biological activity of inulin, improve the extraction efficiency and purity, and overcome the reduction of the activity of inulin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

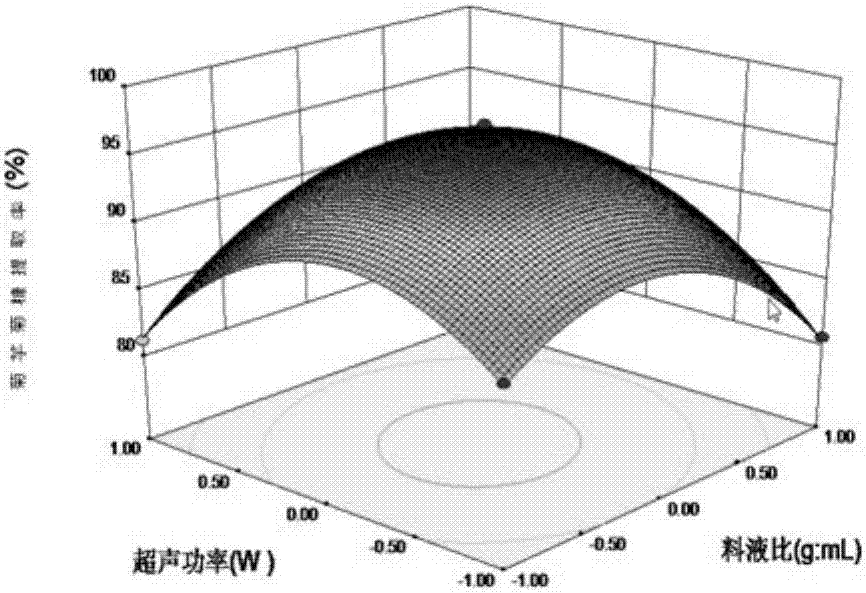

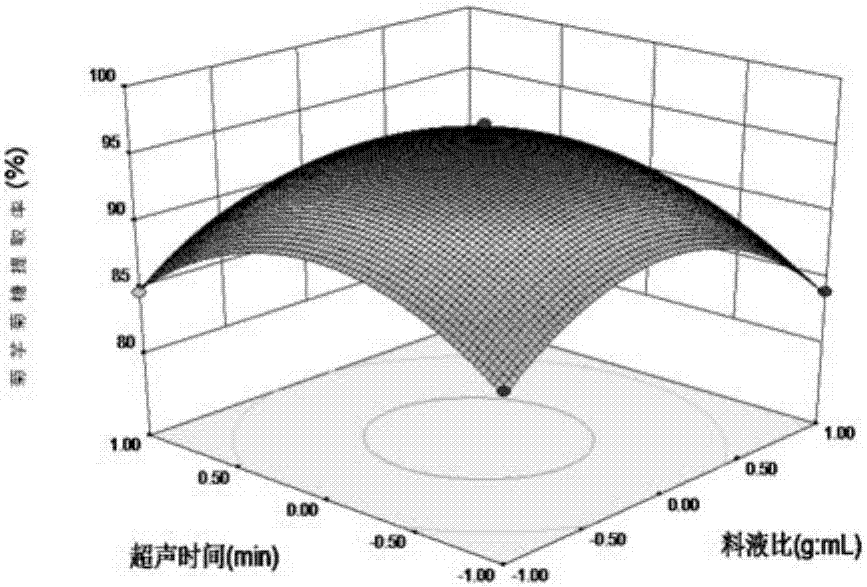

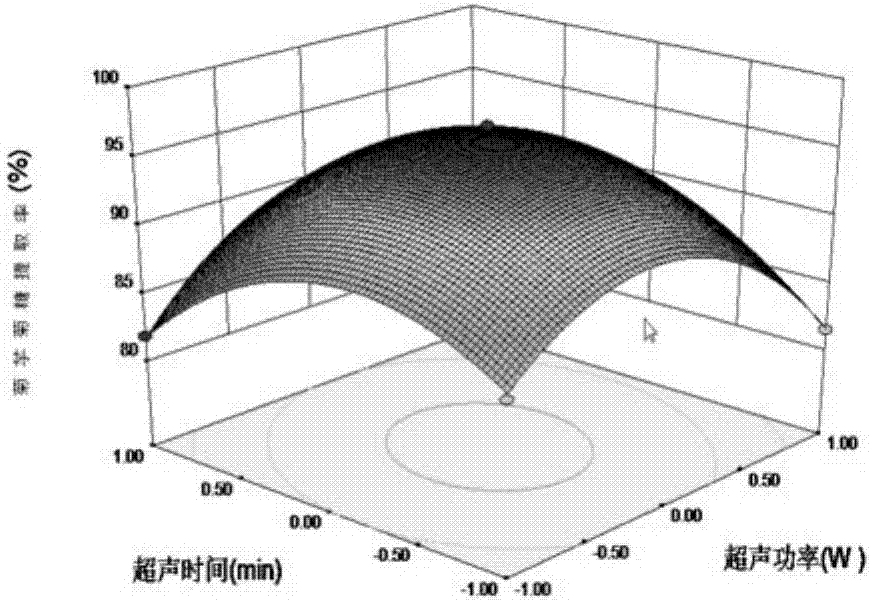

Method used

Image

Examples

Embodiment 1

[0051] Select 100kg of fresh Jerusalem artichokes that are free of disease and mildew, wash them with running water, cut them into thin slices with a thickness of 1-2cm, blanch them at 95-100°C for 1-2min, then add 500L of pure water to mix, beat, and make slurry Place in ultrasonic equipment, ultrasonically treat for 30min at 500W ultrasonic power and temperature at 50°C, put the obtained Jerusalem artichoke ultrasonic treatment liquid into a 1-ton fermenter, and inoculate active dry yeast (Saccharomyces cerevisiae) at a mass percentage of 0.05% in the fermenter Fermentation agent, constant temperature fermentation at 25°C for 3 days to obtain the Jerusalem artichoke fermentation liquid; the Jerusalem artichoke fermentation liquid was placed in an ultrasonic device, and ultrasonically treated at 500W ultrasonic power and a temperature of 50°C for 20 minutes to obtain the second extraction liquid of the Jerusalem artichoke; the second extraction of the Jerusalem artichoke The s...

Embodiment 2

[0053] Select 100kg of fresh Jerusalem artichokes that are free from disease and mildew, wash them under running water, cut them into thin slices with a thickness of 1-2cm, blanch them at 95-100°C for 1-2min, then add 700L of pure water to mix, beat, and make a slurry Place in ultrasonic equipment, ultrasonically treat for 50min under the conditions of 700W ultrasonic power and temperature of 55°C, put the obtained Jerusalem artichoke ultrasonic treatment liquid into a 1 ton fermenter, and inoculate active dry yeast (Saccharomyces cerevisiae) in a mass percentage of 0.03% in the fermenter Fermentation agent, constant temperature fermentation at 28°C for 2 days to obtain the Jerusalem artichoke fermentation liquid; put the Jerusalem artichoke fermentation liquid in an ultrasonic device, and ultrasonically treat it at 700W ultrasonic power and a temperature of 55°C for 15 minutes to obtain the second extraction liquid of the Jerusalem artichoke; the second extraction of the Jerusa...

Embodiment 3

[0055] Select 100kg of fresh Jerusalem artichokes that are free from disease and mildew, wash them with running water, cut them into thin slices with a thickness of 1-2cm, blanch them at 95-100°C for 1-2min, then add 600L of pure water to mix and beat, and put the slurry in In the ultrasonic equipment, under the condition of ultrasonic power of 600W and temperature of 60°C, ultrasonic treatment was performed for 60min, and the obtained Jerusalem artichoke ultrasonic treatment liquid was put into a 1 ton fermenter, and the active dry yeast (Saccharomyces cerevisiae) was inoculated with 0.02% mass percentage in the fermenter for fermentation The Jerusalem artichoke fermented liquid was obtained by constant temperature fermentation at 28°C for 3 days; the Jerusalem artichoke fermented liquid was placed in an ultrasonic device, and ultrasonically treated at 600W ultrasonic power and a temperature of 50°C for 20min to obtain the second extract of Jerusalem artichoke; the second extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com