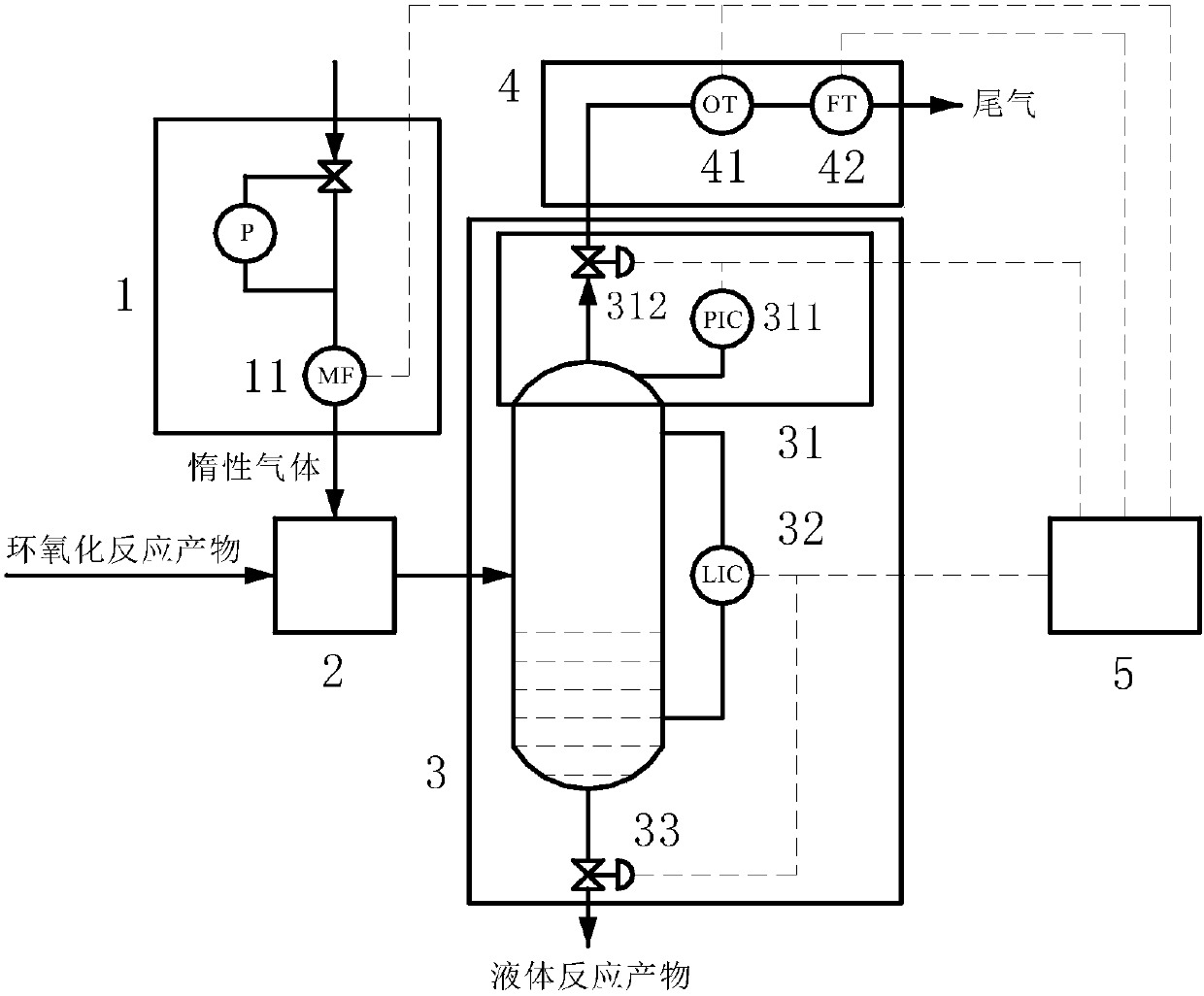

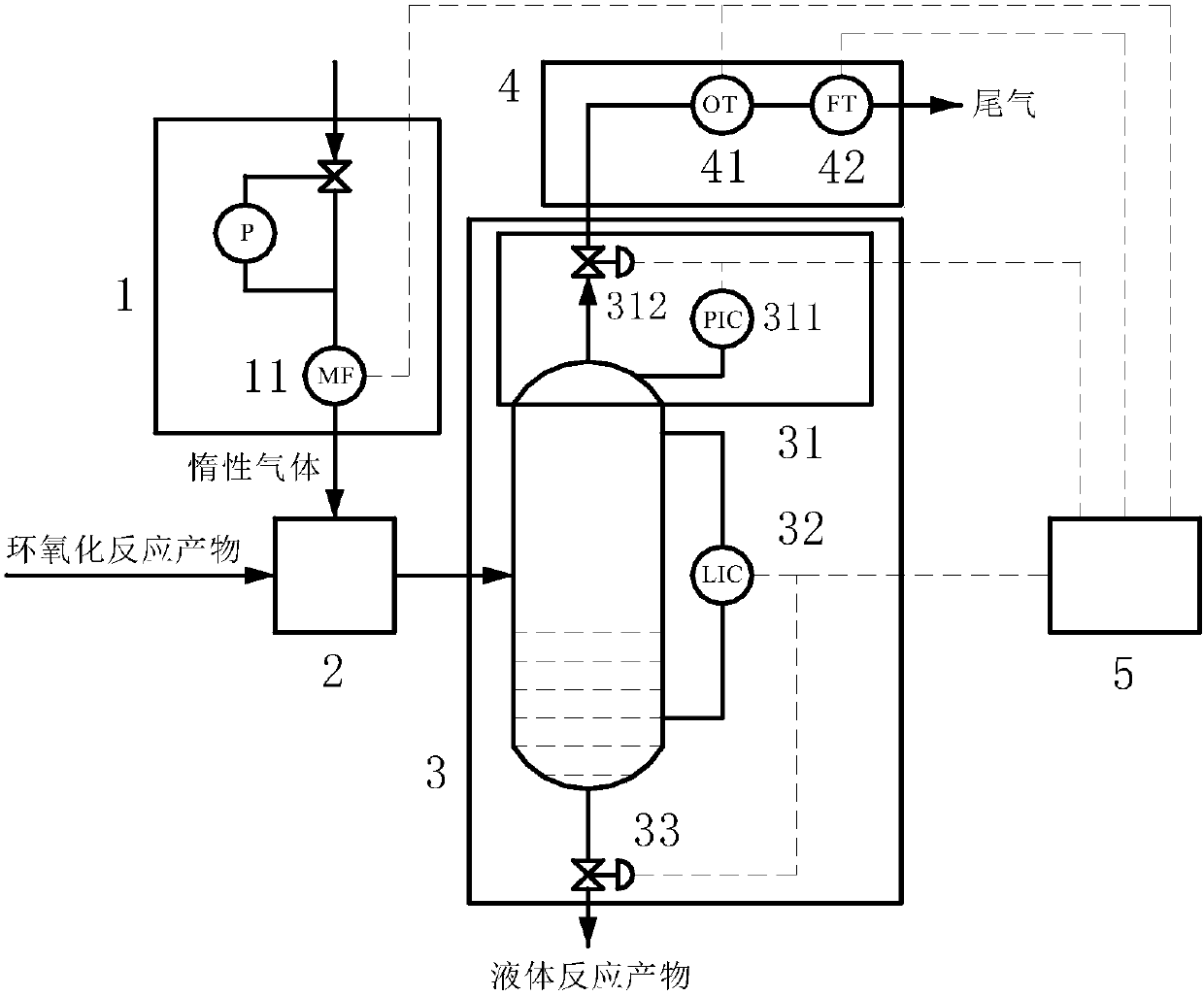

Control device for oxygen content in exhaust gas of oxygen-containing liquid-phase material and control method for oxygen content in exhaust gas of oxygen-containing liquid-phase material

A control device and oxygen content technology, applied in the direction of non-electric variable control, multi-fluid ratio control, ratio control, etc., can solve the problem of exhaust gas explosion and other problems, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] During the epoxidation reaction, first fill the epoxidation reaction system and the oxygen content control device with nitrogen, and control the pressure of the gas-liquid separation tank at 0.5MPa, and then manually control the feed flow of nitrogen at 0.330 kg / hour (20SLM is equivalent to 1.5 kg / hour), then open the epoxidation reaction feed and carry out the epoxidation reaction, after the epoxidation reaction product flows out from the fixed bed reactor outlet, after being cooled to 20 ℃ through the heat exchanger, it is mixed with nitrogen gas The nitrogen gas in the feed line is mixed and directly enters the middle part of the gas-liquid separation tank to be separated into an upward-flowing non-condensable gas and a downward-flowing liquid. The flow meter and oxygen analyzer installed on the tail gas pipeline measure the flow rate and oxygen content respectively, and the liquid is discharged into the storage tank of the liquid epoxidation product through the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com