Nanometer material and preparation method thereof, and photoelectric device

A nanomaterial and nanosheet technology, applied in the field of optoelectronic devices, can solve the problems of high cost, complex preparation process, low hole injection efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

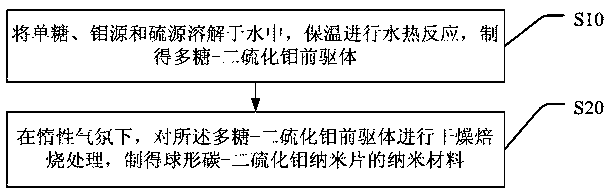

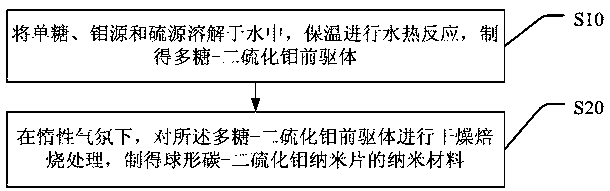

[0024] see figure 1 , figure 1 A flow chart of a preferred embodiment of a nanomaterial preparation method provided by the present invention, as shown in the figure, includes steps:

[0025] S10, dissolving monosaccharide, molybdenum source and sulfur source in water, keeping warm for hydrothermal reaction, and preparing polysaccharide-molybdenum disulfide precursor;

[0026] S20. Drying and calcining the polysaccharide-molybdenum disulfide precursor under an inert atmosphere to prepare spherical carbon-molybdenum disulfide nanosheet nanomaterials.

[0027] In this embodiment, the monosaccharide is dehydrated and polycondensed into a polysaccharide template under hydrothermal conditions, and the space confinement effect of the polysaccharide in situ template can effectively confine MoS 2 Growth of nanosheets in the crystal c-direction to generate ultrathin MoS 2 Nanosheets.

[0028] Specifically, the molybdenum source and the sulfur source generate MoS under hydrothermal c...

Embodiment 1

[0044] 1, the preparation method of nanometer material comprises steps:

[0045] 1) Dissolve 1g of glucose, 0.1g of ammonium molybdate and 0.25g of ammonium sulfide into 20ml of water;

[0046] 2) After the glucose, ammonium molybdate and ammonium sulfide are completely dissolved, transfer them to the hydrothermal reaction kettle. o C for 24h, cooled and washed (washed twice with water, washed once with absolute ethanol), and then at 50 o Dry at C to prepare MoS 2 / polysaccharide precursor;

[0047] 3), the MoS 2 / The polysaccharide precursor was heated to 800 °C under an Ar atmosphere o C was calcined for 5 hours to obtain carbon-molybdenum disulfide nanomaterials.

[0048] 2. Application of nanomaterials:

[0049] 1) Dissolve the carbon-molybdenum disulfide nanomaterial in 10ml of NMP, and disperse it ultrasonically to form a carbon-molybdenum disulfide hybrid nano solution of about 0.8M~1M;

[0050] 2) Spin-coat the carbon-molybdenum disulfide hybrid nano solution ...

Embodiment 2

[0053] 1, the preparation method of nanometer material comprises steps:

[0054] 1) Dissolve 1g fructose, 0.1g sodium molybdate and 0.25g thiourea into 20ml water;

[0055] 2) After the fructose, sodium molybdate and thiourea are completely dissolved, transfer them to the hydrothermal reaction kettle. o C for 26h, cooled and washed (washed twice with water, washed once with absolute ethanol), and then at 50 o Dry at C to prepare MoS 2 / polysaccharide precursor;

[0056] 3), the MoS 2 / Polysaccharide precursor was heated to 850C and roasted for 4h under Ar atmosphere to prepare carbon-molybdenum disulfide nanomaterials.

[0057] 2. Application of nanomaterials:

[0058] 1) Dissolve the carbon-molybdenum disulfide nanomaterial in 10ml DMSO, and disperse it ultrasonically to form a carbon-molybdenum disulfide hybrid nano solution of about 0.8M~1M;

[0059] 2) Spin-coat the carbon-molybdenum disulfide hybrid nano solution onto the ITO substrate at 200-300 o C annealing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com