Treatment method for converting acidic tailings into soil

A treatment method and soilization technology, applied in chemical instruments and methods, recycling technology, solid waste removal, etc., can solve the problems of unable to promote the adaptive growth of plants, the soil is strongly alkaline, and the survival rate is low. The effect of increasing cation exchange, increasing soil water holding capacity, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

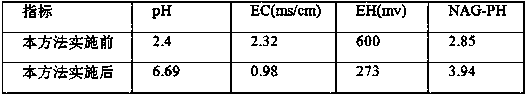

Embodiment 1

[0026] A method for soil treatment of acid tailings, specifically comprising the following steps:

[0027] (1) Raw material preparation: Air-dry the acid tailings and biomass waste separately (dry for 5 hours to make the moisture content below 20%), crush, and sieve (acid tailings and biomass waste pass through a 50-mesh sieve respectively , 100 mesh sieve), spare.

[0028] (2) Combustion: Take 1,000 kg of acid tailings and 3,000 kg of biomass waste, mix the acid tailings with one-third of the biomass waste evenly, make a pile of the mixture, then ignite the mixture pile, and wait for the biomass waste to Fully burn until the flame is extinguished, stir the mixed stockpile and spray with clean water. The amount of spraying is appropriate to ensure that there is no water seeping out of the stockpile.

[0029] (3) Carbonization: Fully mix the mixture treated in step (2) and the remaining biomass waste evenly, and place it in a carbonization furnace for carbonization after dryin...

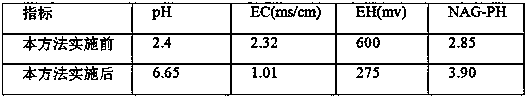

Embodiment 2

[0040] A method for soil treatment of acid tailings, specifically comprising the following steps:

[0041] (1) Raw material preparation: Air-dry the acid tailings and biomass waste separately (dry for 4 hours to make the moisture content below 25%), crush, and sieve (acid tailings and biomass waste pass through a 50-mesh sieve respectively , 100 mesh sieve), spare.

[0042] (2) Combustion: Take 800 kg of acid tailings and 4000 kg of biomass waste, mix the acid tailings with 1 / 4 of the biomass waste evenly, make a pile of the mixture, then ignite the mixture pile, and wait for the biomass waste to Fully burn until the flame is extinguished, stir the mixed stockpile and spray with clean water. The amount of spraying is appropriate to ensure that there is no water seeping out of the stockpile.

[0043] (3) Carbonization: Fully mix the mixed material treated in step (2) with the remaining biomass waste evenly, put it in the carbonization furnace after drying, and first pass N 2 ...

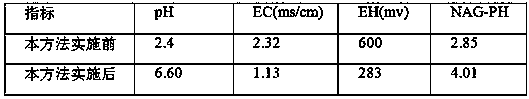

Embodiment 3

[0054] A method for soil treatment of acid tailings, specifically comprising the following steps:

[0055] (1) Raw material preparation: Air-dry the acid tailings and biomass waste separately (dry for 3 hours to make the moisture content below 30%), crush, and sieve (the acid tailings and biomass waste pass through a 50-mesh sieve respectively , 100 mesh sieve), spare.

[0056] (2) Combustion: Take 1200 kg of acid tailings and 5000 kg of biomass waste, mix the acid tailings with one-fifth of the biomass waste evenly, make a pile of the mixture, then ignite the mixture pile, and wait for the biomass waste to Fully burn until the flame is extinguished, stir the mixed stockpile and spray with clean water. The amount of spraying is appropriate to ensure that there is no water seeping out of the stockpile.

[0057] (3) Carbonization: Fully mix the mixture treated in step (2) with the remaining biomass waste evenly, put it in the carbonization furnace after drying, and first pass N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com