Detecting method of content of benzene-type compounds in food contact material

A technology for food contact materials and detection methods, which is applied in the field of headspace-gas chromatography-tandem mass spectrometry detection, can solve the problem of difficult qualitative confirmation of 14 kinds of benzene compounds by gas chromatography, and achieves ensuring accuracy, improving detection sensitivity, and extracting methods. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

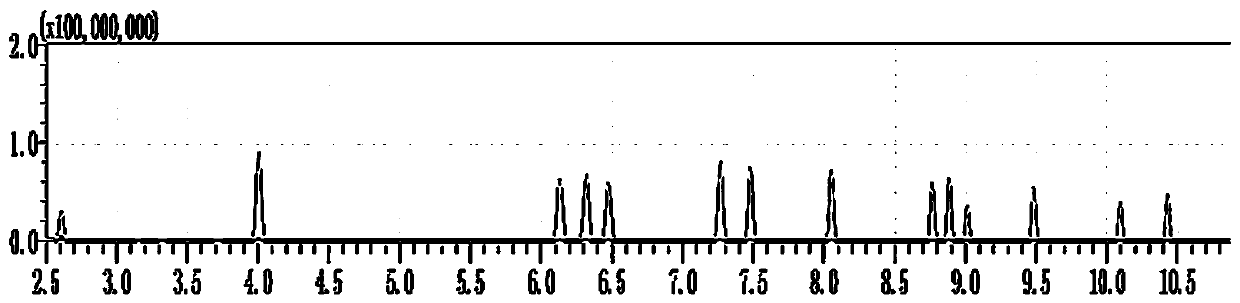

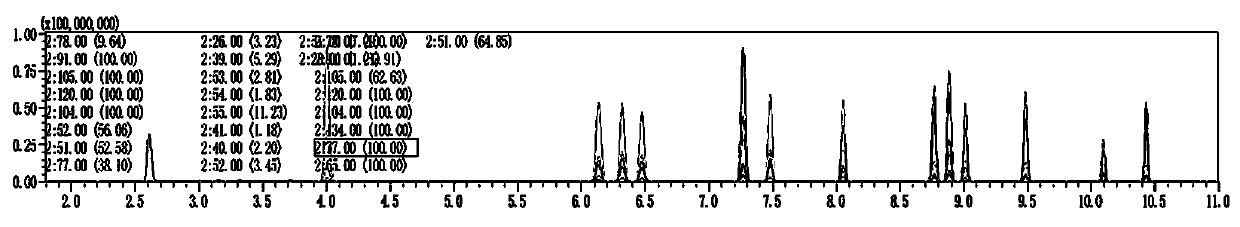

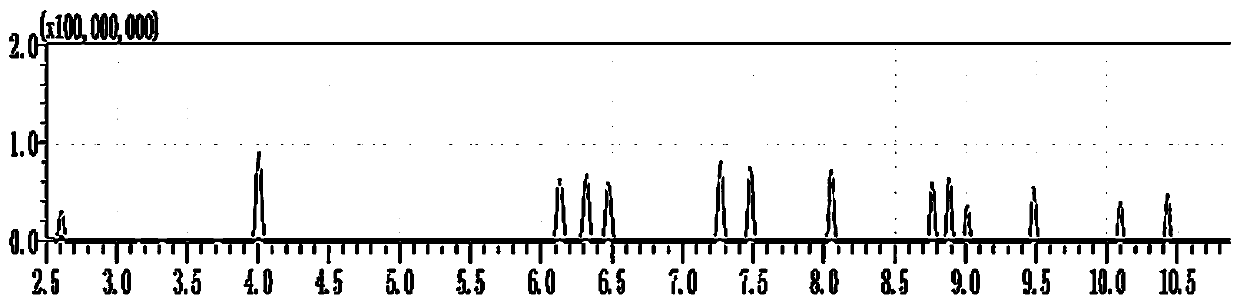

Image

Examples

Embodiment 1

[0036] 1), prepare the sample solution to be tested:

[0037] Take a representative sample of food contact materials, cut it to less than 0.5mm×0.5mm, and mix it as a sample. Weigh 1.0g sample (accurate to 0.0001g), put it in a headspace bottle, accurately add 1~10mL extractant N,N-dimethylacetamide, seal it and shake it well, dissolve it at 20~40℃ for 0.5h ~10h, the solid-liquid ratio of the sample to the extractant is: 1g sample: 10mL extractant.

[0038] 2), prepare standard solution:

[0039] (1) Weigh 0.1g (accurate to 0.00001g) of benzene, toluene, ethylbenzene, styrene, o-xylene, p-xylene, m-xylene, cumene, 1,2,3-trimethylbenzene, n- Propylbenzene, 1,2,4-trimethylbenzene, sec-butylbenzene, n-butylbenzene and 1,3,5-trimethylbenzene standard substances were placed in a volumetric flask, dissolved with N,N-dimethylacetamide and made to volume, Thereby configure the standard stock solution that concentration is 1000mg / L;

[0040] (2) Dilute the above standard stock soluti...

experiment example

[0072] Experiment example: recovery rate experiment and precision experiment

[0073] Add 14 kinds of benzene compounds at a concentration of 20mg / kg to the blank food contact material sample respectively, according to the above pretreatment and analysis method, repeat 6 times for each group, measure and calculate the average recovery rate, and the precision is expressed as relative standard deviation (RSD) Calculated, the recovery rate was 81.0%-117.3%, and the RSD value was 1.3%-9.7%, meeting the test requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com