Zinc organic battery and application thereof

A technology of organic batteries and organic solvents, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as failure to meet grid energy storage applications, hidden safety hazards, and difficulties in recycling, so as to overcome dendrite problems and improve safety The effect of high reliability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

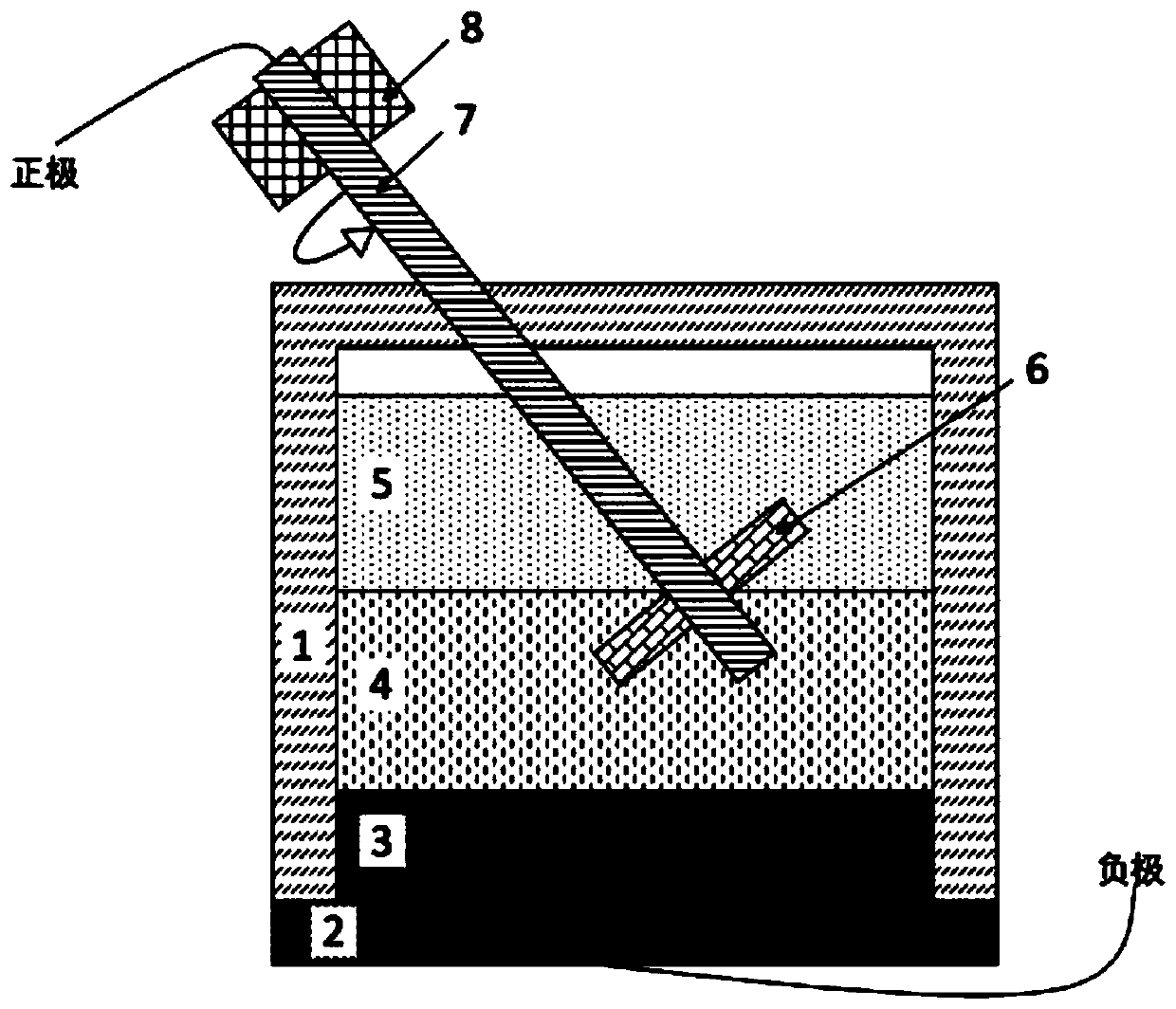

[0066] As attached to the manual figure 1 As shown, a stainless steel tank with an inner diameter of 10 cm, a wall thickness of 0.3 mm, and a height of 10 cm is used as a container; the inner wall surface has a layer of polypropylene lining with a thickness of 2 mm to play the role of insulation, while There is no polypropylene liner on the bottom, which acts as the negative current collector for the battery. Put 5 grams of zinc powder in the container as the zinc negative electrode, and contact with the bottom of the stainless steel pipe to ensure electric conduction. Add 30 milliliters of 5mol / L zinc bromide aqueous solution into the container as an aqueous electrolyte, the bromide ion in the aqueous electrolyte is the reduced state of the positive active material, and its oxidation state is bromine and tribromide ions. Then add 30 milliliters of hexanoic acid as an organic solvent. At room temperature, hexanoic acid is only slightly soluble in water, and most of the hexano...

Embodiment 2

[0069] Using the same battery structure as in Example 1, change the material added to the container: first add 100 grams of zinc powder to the container as a zinc negative electrode, and then add 20 ml of 1mol / L zinc chloride aqueous solution as an aqueous electrolyte. Then add 40 milliliters of 1mol / L tetrachloro-p-benzoquinone in 1,4-dioxane solution, tetrachloro-p-benzoquinone is the oxidation state of positive electrode active material, insoluble in water, and its reduced state is tetrachlorohydroquinone .

[0070] After the battery is manufactured, it is in a charging state and can be discharged directly. The discharge voltage is 1.1V and the capacity is 2000 mAh; the charging voltage is 1.5V and the Coulombic efficiency is 95%; after 1000 cycles, the discharge capacity is 1800 mAh.

Embodiment 3

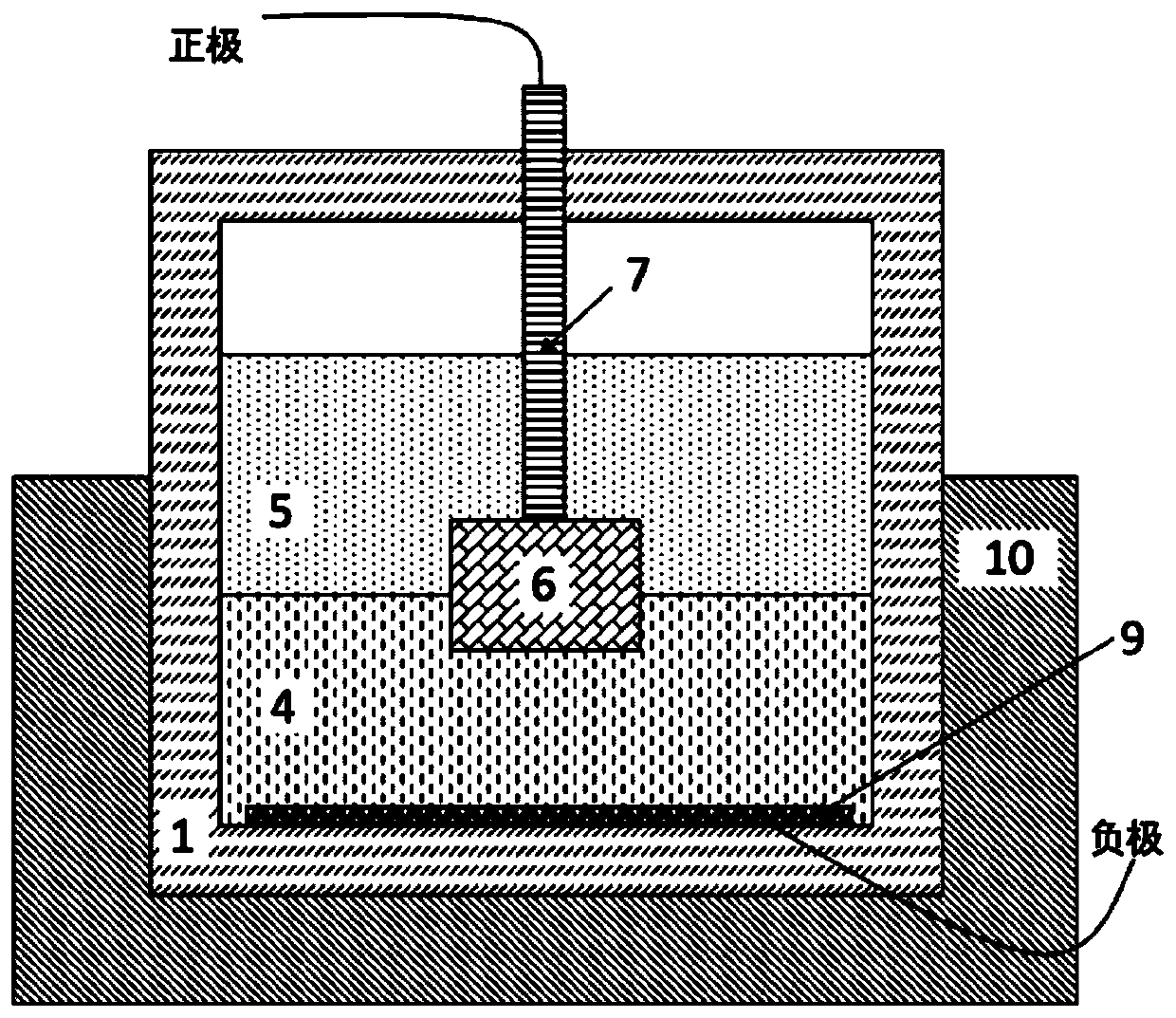

[0072] As attached to the manual figure 2 As shown, a sealed polypropylene storage tank with an inner diameter of 10 cm, a wall thickness of 0.3 mm, and a height of 10 cm is used as a container. A twist of carbon fiber is used as a wire to pass through a small hole (0.2mm in diameter) at the bottom of the storage tank, and is in good contact with a piece of circular graphite felt with a diameter of 5cm and a thickness of 0.5cm at the bottom of the container, and the small hole is well sealed. The graphite felt is coated with 5g of zinc. The advantage of using carbon fiber to connect external circuits is that the carbon fiber will not be corroded by aqueous electrolyte and organic solution during long-term use. There is another 30ml of aqueous electrolyte in the container. The aqueous electrolyte includes magnesium sulfate, zinc chloride and ammonium chloride. The concentration of magnesium sulfate is 150g / L, the concentration of zinc chloride is 50g / L, and the concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com