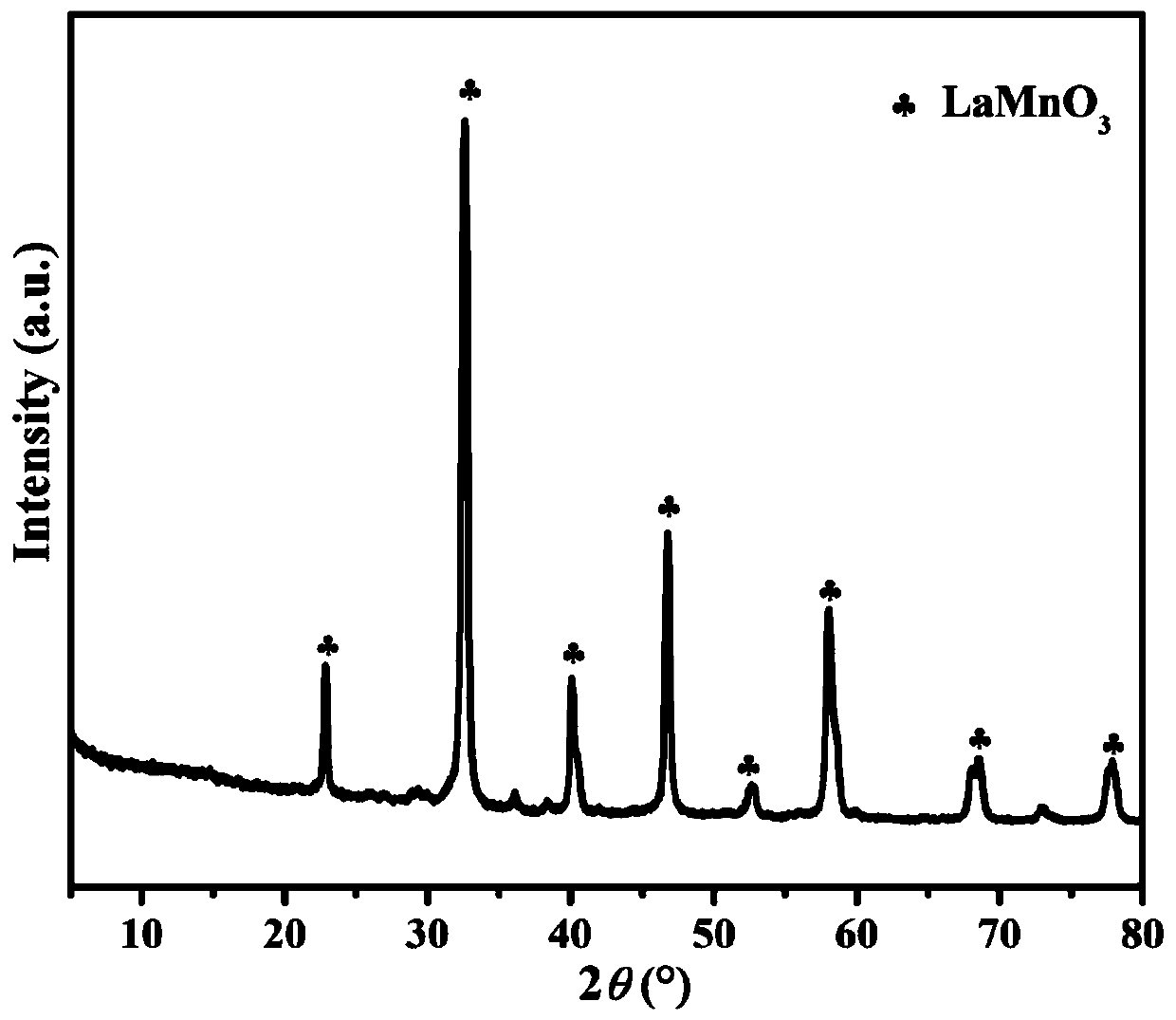

Ce-doped LaMnO3 catalyst and preparation method thereof

A catalyst and element doping technology, used in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to improve redox capacity and electron transfer rate, and excellent VOCS removal high performance, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

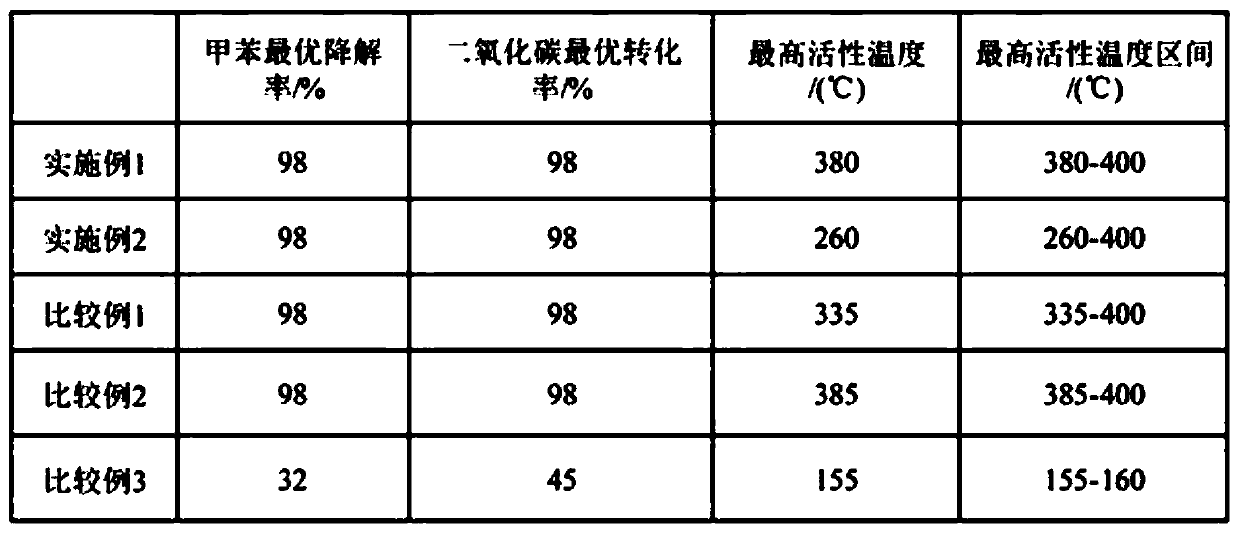

Examples

Embodiment 1

[0016] Step (1): Weigh about 2.4509 g of manganese acetate, 4.2028 g of citric acid, 2.4369 g of lanthanum nitrate, 6 g of polyethylene glycol, and 1.0856 g of cerium nitrate into a beaker, dissolve in ethanol, and stir for 1 hour with a magnetic stirrer .

[0017] Step (2): The product obtained in step (1) was dried in a constant temperature water bath at 70°C until it became gelatinous. The resulting gel was placed in a crucible and baked in a muffle furnace at 700°C for 7 hours.

[0018] Step (3): Doping Ce obtained in step (2) (La 0.75 Ce 0.25 MnO 3 ) Grind and sieve 40-60 mesh for later use.

Embodiment 2

[0020] Step (1): Weigh about 2.4509 g of manganese acetate, 4.2028 g of citric acid, 3.2492 g of lanthanum nitrate, and 6 g of polyethylene glycol, add them into a beaker, dissolve them in ethanol, and stir for 1 hour with a magnetic stirrer.

[0021] Step (2): The product obtained in step (1) was dried in a constant temperature water bath at 70°C until it became gelatinous, and the obtained gel was placed in a crucible and baked in a muffle furnace at 700°C for 7 hours.

[0022] Step (3): LaMnO obtained in step (2) 3 Grind and sieve 40-60 mesh for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com