Low-water low-defect ferrocyanide manganese potassium Prussian blue cubic crystal and preparation method thereof

A technology of potassium ferrocyanide manganese and Prussian blue, applied in cyanic acid/isocyanic acid and other directions, can solve the problems of increased material preparation cost, cannot be reduced, energy consumption, etc., achieves good economic and application value, easy to operate, reduce The effect of nucleation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing the above-mentioned low-water and low-defect potassium manganese ferrocyanide Prussian blue cubic crystal, which comprises the following steps:

[0050] A. Dissolving potassium ferrocyanide and complexing agent in deionized water to obtain solution A; the molar ratio of potassium ferrocyanide and complexing agent in solution A is 1:20-100;

[0051] B, dissolving the soluble manganese salt in deionized water to obtain solution B;

[0052] C. Drop solution B into solution A, keep warm for reaction, and after the reaction, cool, separate solid and liquid, wash and dry to obtain potassium ferrocyanide Prussian blue cubic crystals.

[0053] The present invention adopts high-concentration complexing agent to improve the combination of complexing agent and Mn ions, thereby realizing the slow release of Mn ions from the complex during the precipitation process and slowing down the precipitation reaction speed; in additi...

Embodiment 1

[0061] Embodiment 1: high temperature+high complexing agent concentration

[0062] A. Dissolve 0.003mol potassium ferrocyanide trihydrate, 0.1mol sodium citrate dihydrate and 0.1mol potassium citrate monohydrate in 100mL deionized water to obtain solution A, keep the temperature of solution A at 70°C; wherein, The molar ratio of potassium ferrocyanide and citrate complexing agent is 1:67;

[0063] B. Dissolve 0.006mol of manganese nitrate tetrahydrate in 50mL of deionized water to obtain solution B, and keep the temperature of solution B at 70°C;

[0064] C. Drop solution B into solution A at a rate of 0.5mL / min, keep warm at 70°C for 12 hours, after the reaction, cool, wash and centrifuge the precipitate several times, and finally dry it in an ordinary oven at 80°C Dry for 12 hours to obtain potassium ferrocyanide Prussian blue cubic crystals.

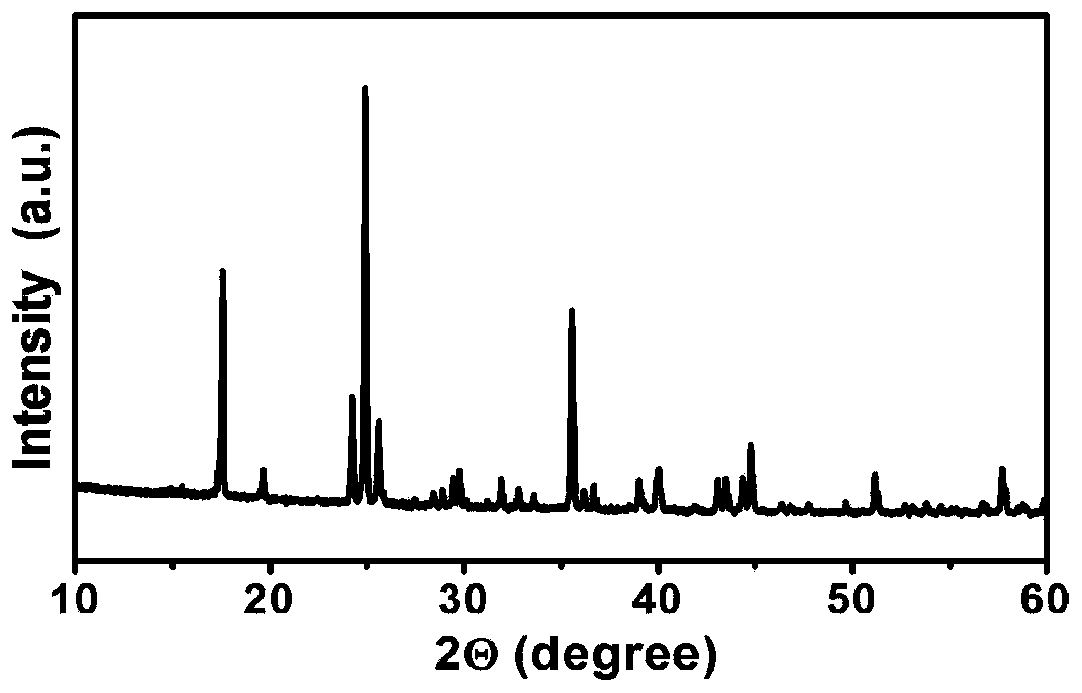

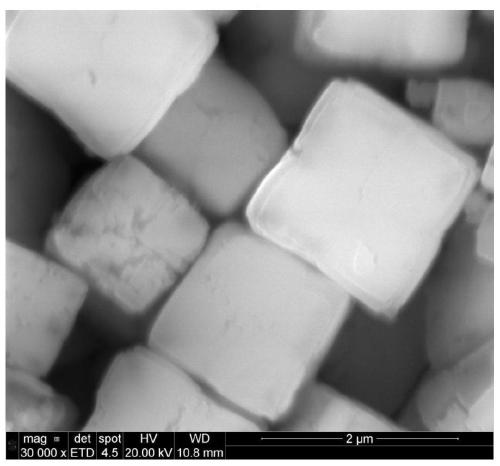

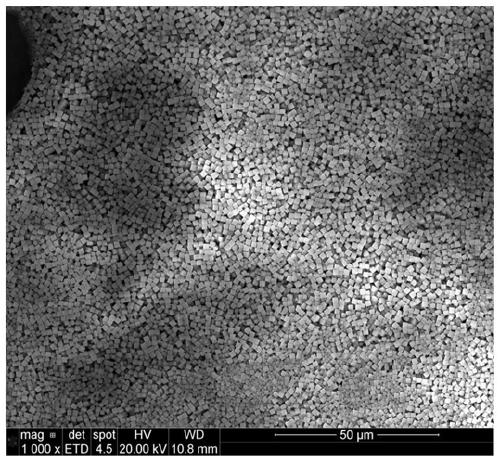

[0065] figure 1 It is the X-ray diffraction pattern of the material obtained in this embodiment, figure 2 and image 3 A scann...

Embodiment 2

[0066] Embodiment 2: high temperature+high complexing agent concentration

[0067] A, 0.003mol potassium ferrocyanide trihydrate, 0.03mol sodium oxalate and 0.03mol potassium oxalate are dissolved in 50mL deionized water to obtain solution A, keep the temperature of solution A at 95°C; the potassium ferrocyanide and The molar ratio of oxalate complexing agent is 1:20;

[0068] B. Dissolve 0.0045mol of manganese sulfate monohydrate in 100mL of deionized water to obtain solution B, and keep the temperature of solution B at 95°C;

[0069] C. Drop solution B into solution A at a rate of 1mL / min, keep warm at 95°C for 2 hours, after the reaction, cool, wash and centrifuge the precipitate several times, and finally dry it in an ordinary oven at 80°C After 12 hours, potassium ferrocyanide manganese Prussian blue cubic crystals were obtained.

[0070] Figure 6 It is the X-ray diffraction pattern of the material obtained in this embodiment, Figure 7 and Figure 8 A scanning elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com