A kind of sodium bismuth titanate nanotube and preparation method thereof

A technology of sodium bismuth titanate and nanotubes, applied in nanotechnology, chemical instruments and methods, bismuth compounds, etc., can solve the difficult piezoelectric coefficient of one-dimensional lead-free piezoelectric materials, incompatibility with high aspect ratio, and complicated process etc. to achieve the effects of low cost, improved piezoelectric performance, and larger specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

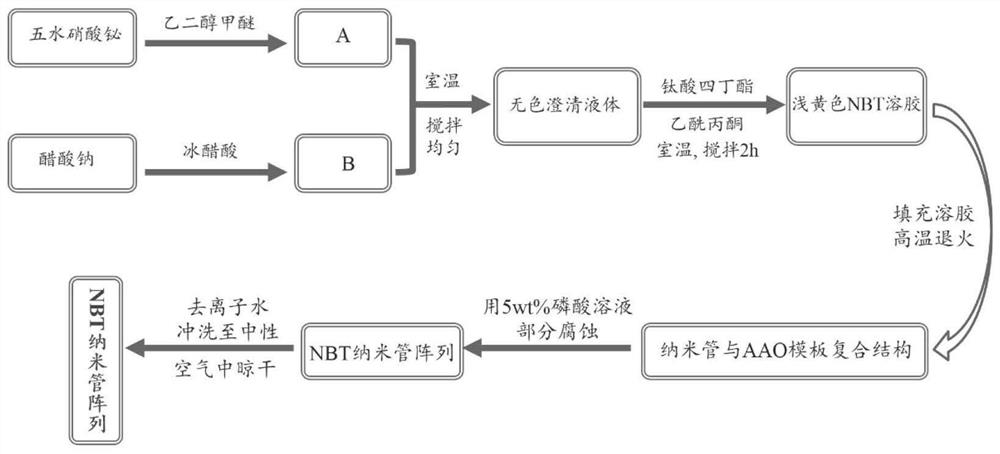

[0114] Step 1: Prepare NBT precursor solution

[0115] (1) Weigh 1.078g Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL CH 3 OCH 2 CH 2 OH and magnetically stirred, recorded as A solution, its mass volume ratio is 0.072g / mL;

[0116] (2) Weigh 0.166g CH 3 COONa was dissolved in 3 mL CH 3 COOH and stirred evenly, recorded as B solution, its mass volume ratio is 0.055g / mL;

[0117] (3) Add solution B to solution A dropwise, and magnetically stir the resulting mixed solution for 20 minutes;

[0118] (4) Add 1.375g Ti(OC 4 h 9 ) 4 , 1mL CH 3 COCH 2 COCH 3 , stirred at room temperature for 2h to obtain a uniformly mixed precursor solution, see the accompanying drawings of the present invention figure 1 ;

[0119] above CH 3 COONa, Bi(NO 3 ) 3 Aqueous solution, Ti(OC 4 h 9 ) 4 Amount of aqueous solution, according to CH 3 COONa: Bi(NO 3 ) 3 : Ti(OC 4 h 9 ) 4 The molar ratio is calculated as the ratio of 1:1:2;

[0120] Step 2: Swirl

[0121] Soak the AAO templat...

Embodiment 2

[0124] A preparation method of NBT nanotube array, comprising the steps of:

[0125] The other conditions are the same as in Example 1, only step 2 uses AAO template (template pore size is 110nm), repeats the steps of suction filtration and spin coating for 4 times, and finally obtains an NBT nanotube array with a diameter of about 110nm.

Embodiment 3

[0127] A preparation method of NBT nanotube array, comprising the steps of:

[0128] Other conditions are the same as in Example 1, only the AAO template is used in step 2 (the pore size of the template is 30nm), and the steps of repeated suction filtration and spin coating are 2 times, and the AAO template containing the sol needs to be placed in a muffle after the first repetition of the steps The annealing process is carried out in the furnace. The annealing process parameters are as follows: the temperature is raised from room temperature to 175°C, and the temperature is kept for 2 minutes;

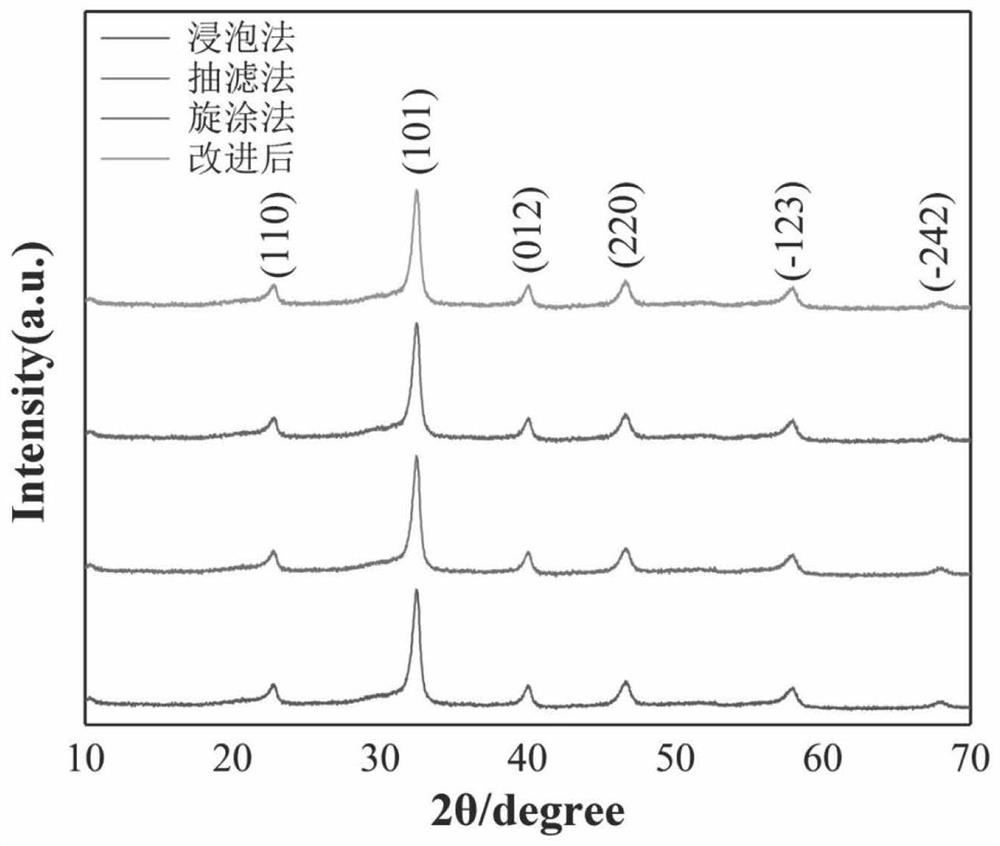

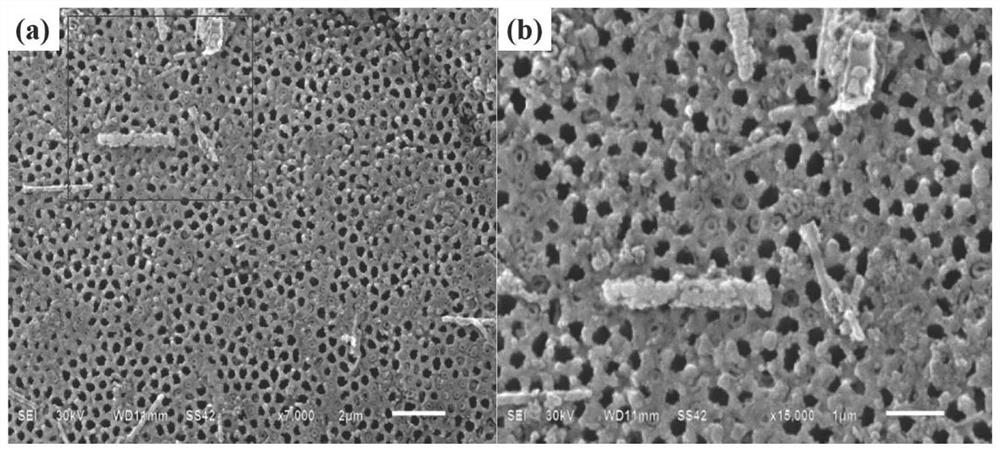

[0129] In summary, the present invention provides a high-voltage electric coefficient sodium bismuth titanate nanotube and a preparation method thereof. By comparing the formation mechanism of NBT nanotube arrays prepared by different filling methods, a high filling rate and a large aspect ratio are found. 1. The preparation method of NBT nanotube arrays with precisely controlled wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com