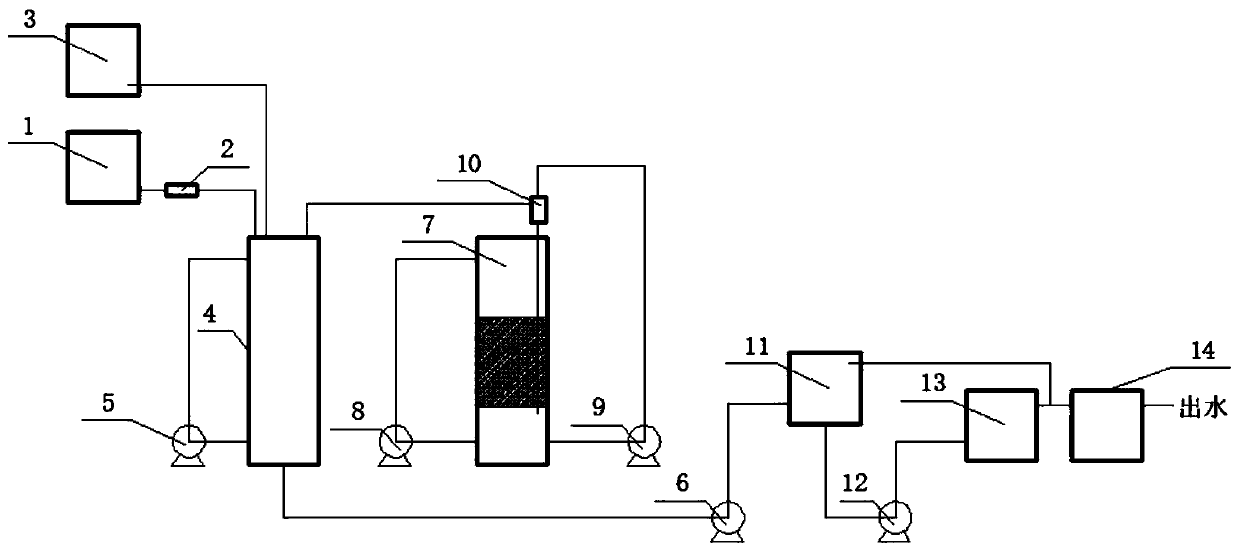

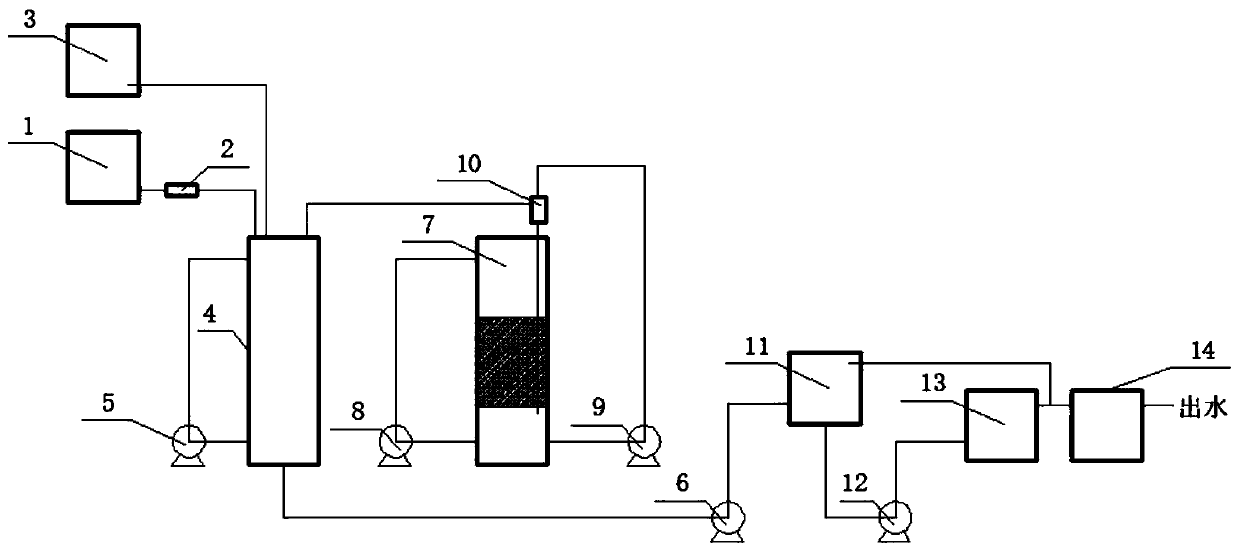

Cyanide-containing wastewater purification and cyanide recovering device and recovering method

A recovery method and recovery device technology, applied in the direction of metal cyanide, chemical instruments and methods, simple alkali metal cyanide, etc., can solve problems such as safety, achieve the effect of shortening the process flow, shortening the reaction time, and avoiding the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Cyanide-containing wastewater from a gold mine, pH 11.8, CN f 3674.02mg / L, SCN - 12918.26mg / L, Cu 2+ 2138.06mg / L, Zn 2+ It is 808mg / L. The waste water is treated by the steps of the present invention, and the pH of the acidizing solution is controlled to be 1.5. When the circulation ratio of the acidifying solution (the flow rate of the circulating liquid and the flow rate of the incoming liquid) is 1:1, that is, the reaction time is 1h, and the acidifying solution CN f to 710.87mg / L, continue to increase the acidizing solution circulation ratio to 2:1, that is, the reaction time is 2h, the acidifying solution CN f 103.56mg / L, SCN - 5961.74mg / L, Cu 2 + 4.60mg / L, Zn 2+ 0.21mg / L. After the acidification liquid is separated from the solid and liquid after treatment, the copper grade in the acidification slag is 25.65%. The liquid is neutralized and then returned to the cyanide section for recycling. At the same time, HCN in the tail gas is not detected, and the abso...

example 2

[0035] Cyanide-containing wastewater from a gold mine, pH 10.7, CN f 749.27mg / L, SCN - 2251.59g / L, Cu 2+ 406.98mg / L, Zn 2+ It is 190.00mg / L. The waste water is treated through the above steps, and the pH of the acidizing solution is controlled to be 1.5. When the circulation ratio of the acidifying solution (the flow rate of the circulating liquid and the flow rate of the influent liquid) is 2:1, that is, the reaction time is 2 hours, and the acidifying solution CN f 103.56mg / L, SCN - 1289.78mg / L, Cu 2+ 1.60mg / L, Zn 2+ The copper grade in the acidified slag is 0.12mg / L. After the treatment, the acidified liquid is separated from the solid and liquid, and the copper grade in the acidified slag is 21.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com