Post-treatment purification method of pyrrole-pyridine-pyrrole compound

A purification method and compound technology, applied in the direction of organic chemistry, can solve the problems of time-consuming, consumption, multi-solvent, etc., and achieve the effect of shortening the reaction time, high product purity, and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

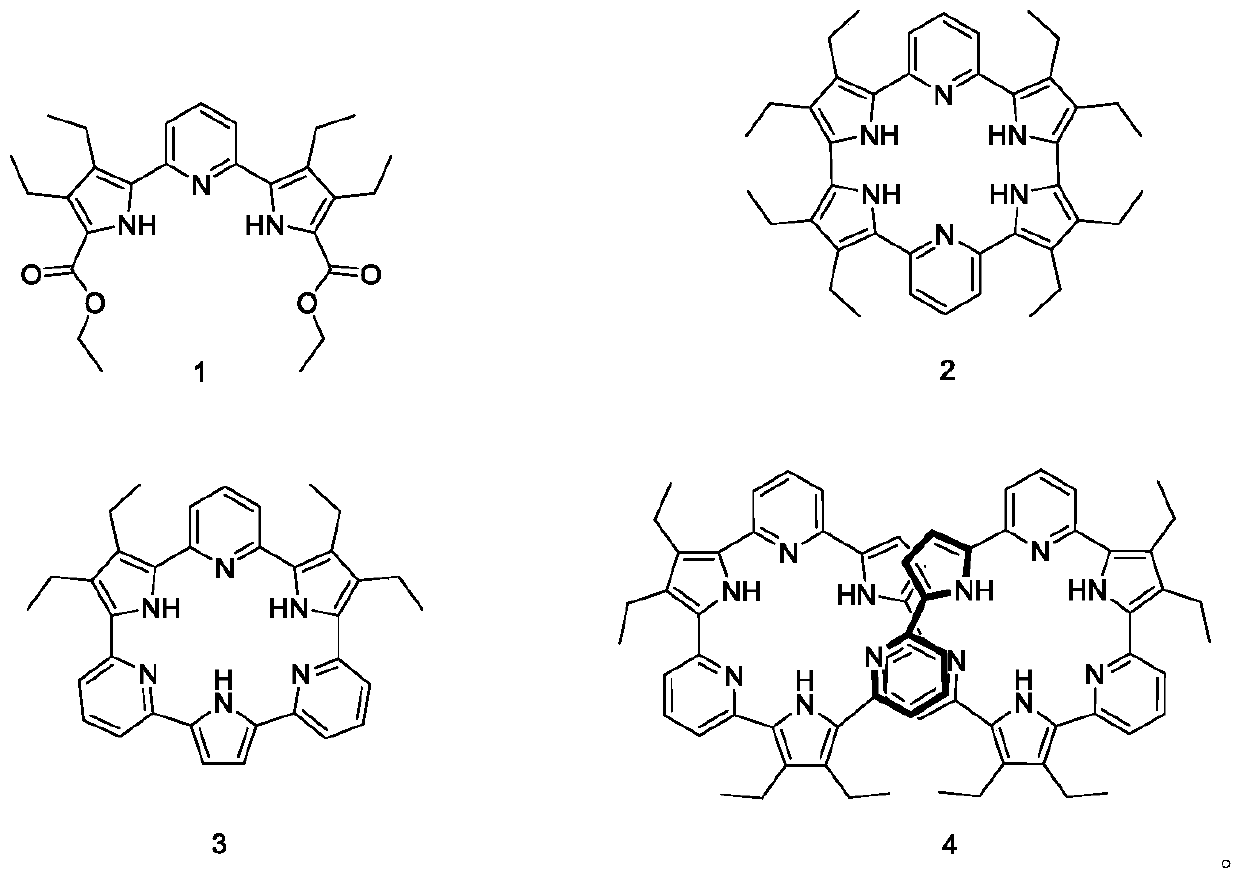

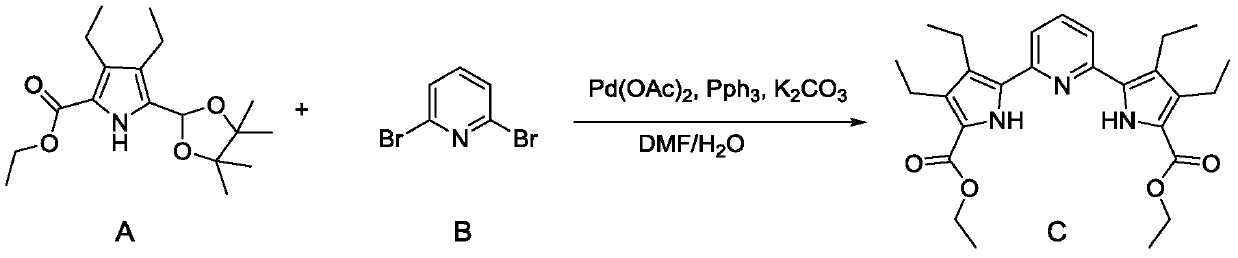

[0026] This example expands the synthesis of a pyrrole-pyridine-pyrrole compound as an example of a porphyrin intermediate. The synthetic reaction equation is as follows:

[0027]

[0028] Including the following steps:

[0029] (1) Add compound B (0.3070g), palladium acetate (0.0291g), triphenylphosphine (0.0681g) and potassium carbonate (0.5916g) in a round bottom flask of appropriate size;

[0030] (2) remove the air in the bottle under reduced pressure, blow nitrogen, and repeat three times;

[0031] (3) Add N,N-dimethylformamide (20mL) and water (10mL) under nitrogen protection;

[0032] (4) The system was stirred and reacted at 85°C for about 1 hour;

[0033] (5) A solution of N,N-dimethylformamide (10 mL) dissolved in Compound A (1.0 g) was slowly added dropwise to the system;

[0034] (6) After the dropwise addition, the system was stirred and reacted at 85° C. for 24 hours under the protection of nitrogen;

[0035] (7) reaction finishes, and decompression remov...

Embodiment 2

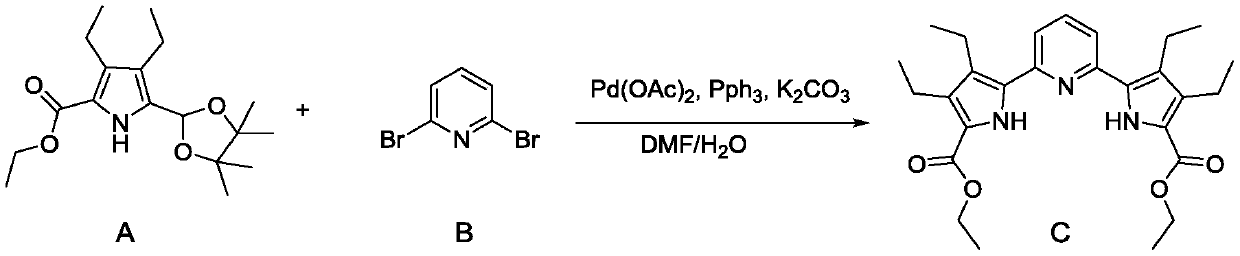

[0041] This example expands the synthesis of a pyrrole-pyridine-pyrrole compound as an example of a porphyrin intermediate. The synthetic reaction equation is as follows:

[0042]

[0043] Including the following steps:

[0044] (1) Add compound B (0.614g), palladium acetate (0.0582g), triphenylphosphine (0.1362g) and potassium carbonate (1.1832g) in a round bottom flask of appropriate size;

[0045] (2) remove the air in the bottle under reduced pressure, blow nitrogen, and repeat three times;

[0046] (3) Add N,N-dimethylformamide (40mL) and water (20mL) under nitrogen protection;

[0047] (4) The system was stirred and reacted at 85°C for about 1 hour;

[0048] (5) A solution of N,N-dimethylformamide (20 mL) dissolved in Compound A (2.0 g) was slowly added dropwise to the system;

[0049] (6) After the dropwise addition, the system was stirred and reacted at 85° C. for 24 hours under the protection of nitrogen;

[0050] (7) reaction finishes, and decompression remove...

Embodiment 3

[0056] This example expands the synthesis of a pyrrole-pyridine-pyrrole compound as an example of a porphyrin intermediate. The synthetic reaction equation is as follows:

[0057]

[0058] Including the following steps:

[0059] (1) Add compound B (1.5350g), palladium acetate (0.1455g), triphenylphosphine (0.3405g) and potassium carbonate (2.9580g) in a round bottom flask of appropriate size;

[0060] (2) remove the air in the bottle under reduced pressure, blow nitrogen, and repeat three times;

[0061] (3) Add N,N-dimethylformamide (100mL) and water (50mL) under nitrogen protection;

[0062] (4) The system was stirred and reacted at 85°C for about 1 hour;

[0063] (5) A solution of N,N-dimethylformamide (50 mL) dissolved in compound A (5.0 g) was slowly added dropwise to the system;

[0064] (6) After the dropwise addition, the system was stirred and reacted at 85° C. for 24 hours under the protection of nitrogen;

[0065] (7) reaction finishes, and decompression remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com