Preparation method of high-performance solid buoyancy material

A solid buoyancy and high-performance technology, applied in the field of materials, can solve problems such as poor impact resistance, and achieve the effects of good fluidity, good impact resistance, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

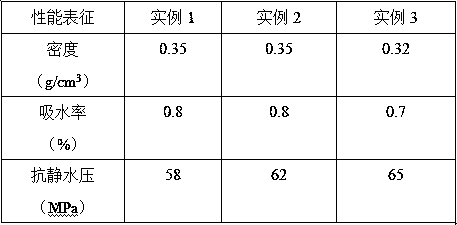

Examples

Embodiment Construction

[0025] In parts by weight, weigh 30-50 parts of sodium silicate, 5-12 parts of 300-400 mesh alumina powder, 10-20 parts of 200-300 mesh waste glass powder, 1-5 parts of urea, 0.2-0.4 The mass fraction is 5% ferric chloride aqueous solution, 0.1 to 0.3 parts of platinum catalyst, sodium silicate, 300 to 400 mesh alumina powder, 200 to 300 mesh waste glass powder and urea, and the stirring speed is 300 to 500r Magnetic stirring at room temperature for 1-2 hours / min to obtain the mixture, sequentially add platinum catalyst and 5% ferric chloride aqueous solution to the mixture, and continue to stir for 1-2 days to obtain the precursor. Dry and granulate in the form of droplets to obtain a green body. Put the green body in an oven, raise the temperature at 2°C / min to 50-60°C and keep it warm for 6-8 hours, then raise the temperature to 80-90°C at 12°C / min Put the semi-finished product in a quartz tube furnace, heat it up to 800-850°C at a heating rate of 5-10°C / min, then inject ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com