Phase change cold storage material for freshness retaining of partial-frozen chilled food and preparation method

A technology of phase change cold storage and food preservation, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing the latent heat value and loss of phase change, achieve excellent phase change heat storage performance, simple equipment, easy to reduce The cost effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

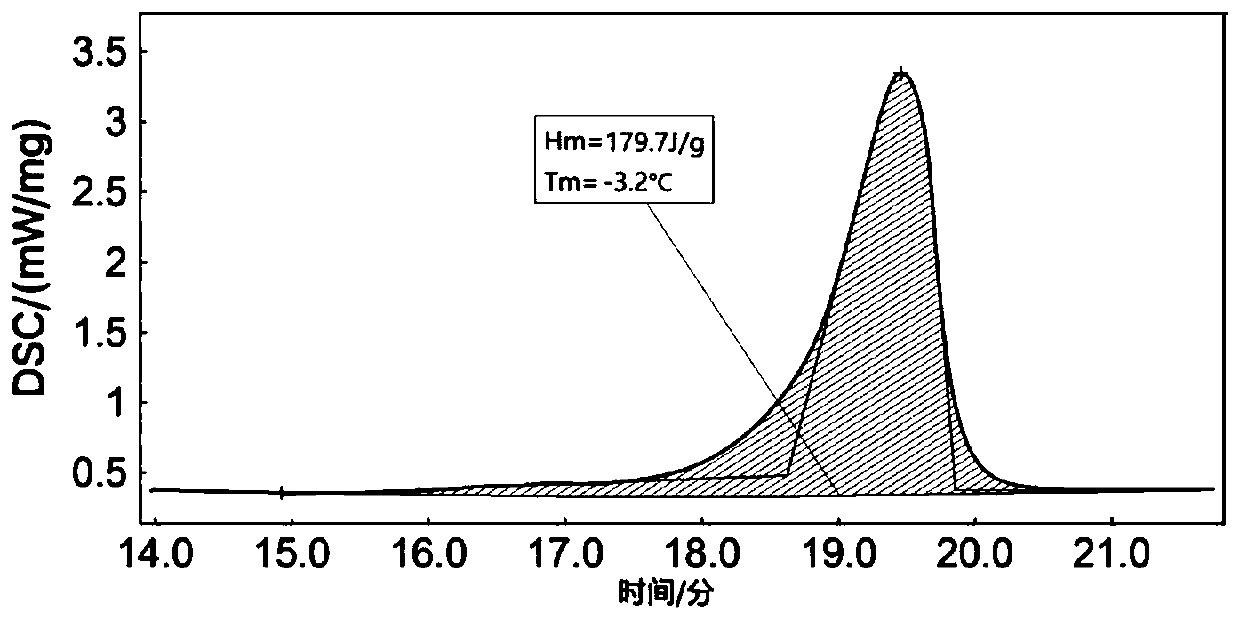

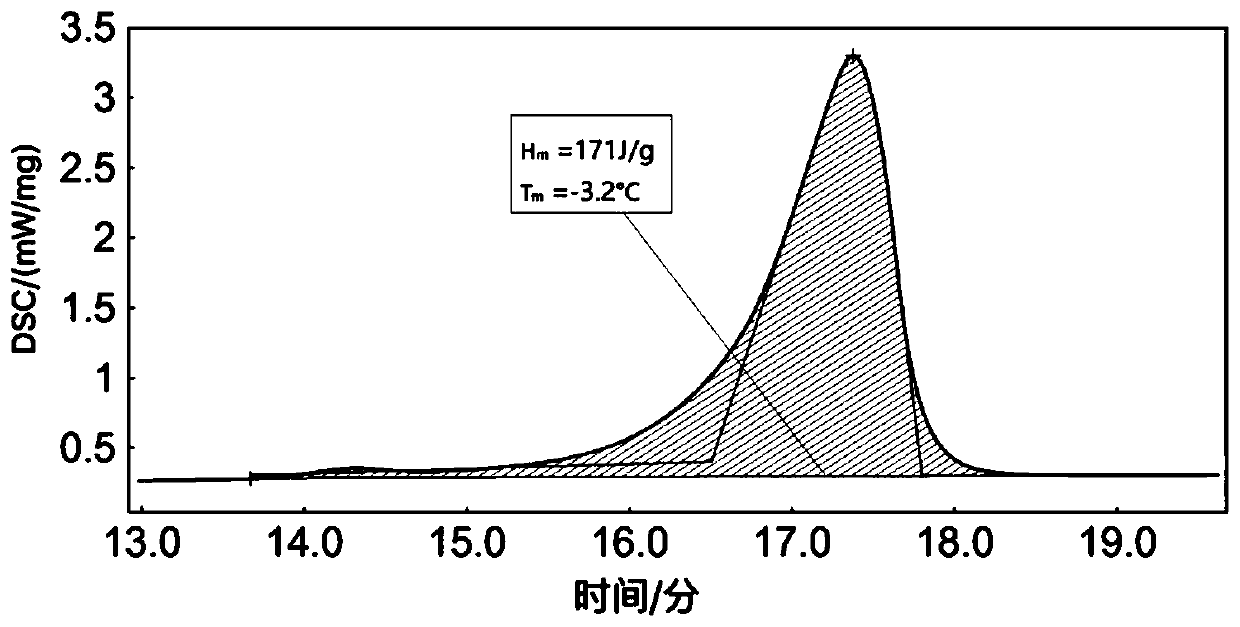

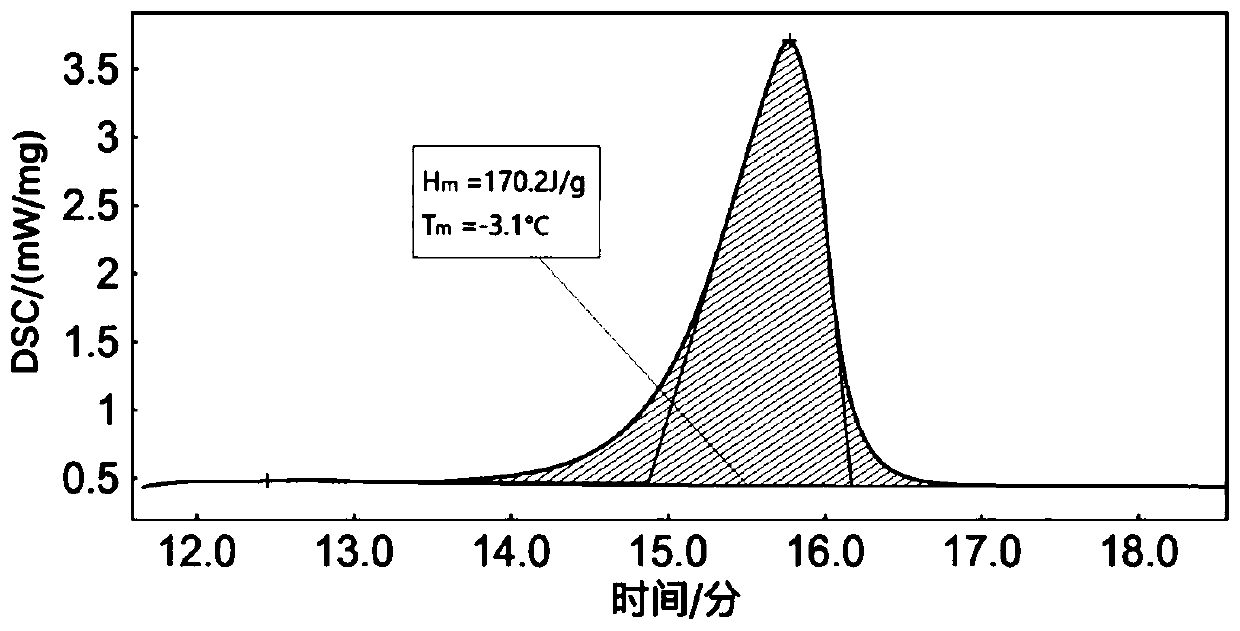

Embodiment 1

[0059] According to theoretical calculation, the minimum eutectic point ratio of decanoic acid and dodecanol is 0.762:0238. In order to verify the accuracy of the theoretical value, the molar mass ratios of 74:26, 75:25, 75:25, and 76:24, 77:23, 78:22 decanol-dodecanol composite phase change materials were verified experimentally. A certain mass of experimental samples was weighed with a precision electronic balance, and the mass of each group of samples was 50 g, which were placed in a beaker with a volume of 100 mL. Put the beaker containing the decyl alcohol-dodecanol mixed solution on a magnetic stirrer, stir for 20mins at a heating temperature of 35°C and a speed of 300r / min to ensure that the two are evenly mixed, and then cool the mixture naturally to room temperature to obtain decano Binary phase transition system of alcohol-dodecanol. From Figure 4 It can be seen from the step cooling curve that the freezing point temperature is the lowest when the mass fraction ra...

Embodiment 2

[0061] Weigh 30g of DA-LA with a mass ratio of 76:24 as the base liquid, and then successively weigh 0.002 parts, 0.004 parts, 0.006 parts, 0.008 parts, and 0.01 parts of hydroxylated multi-walled carbon nanotubes and add them to decanol / dodecanol solution. Ultrasonic dispersion is carried out on the prepared materials. Set the parameters of the ultrasonic disperser, the ultrasonic device oscillates 360 times, a cycle of ultrasonic work for 5 seconds, pause for 5 seconds, the upper temperature limit is set to 45 °C, and the ultrasonic power is 300W. Take out the homogeneously dispersed material by ultrasonic and let it stand at room temperature for later use. The prepared nanocomposite phase change material was left standing at room temperature for 48 hours, and its sedimentation phenomenon was observed. It was found that the five groups of solutions were evenly dispersed and no significant sedimentation occurred. When the nanomaterials are added to a certain mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com