Wear-resistant seamless steel pipe and manufacturing method thereof

A technology of seamless steel pipe and manufacturing method, applied in the field of steel pipe, can solve the problems of heavy material, high comprehensive cost, poor pipe plasticity and weldability, etc., and achieve the effect of single material, simple production process and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

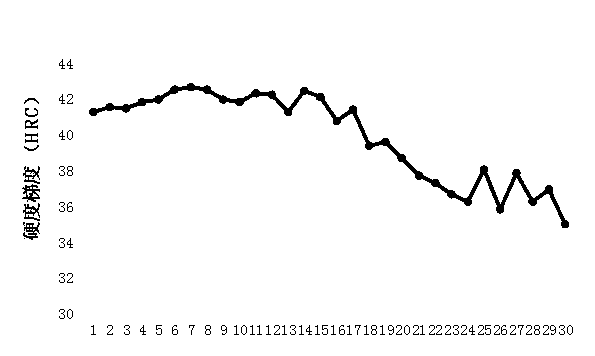

Embodiment 1

[0028] The specification of the seamless wear-resistant steel pipe in this example is 219×7mm, and the length is 12m. The chemical composition of the steel pipe is calculated by mass percentage: 0.14% C, 0.25% Si, 0.7% Mn, 0.013%P, 0.004%S , 0.12% Cr, 0.018% Al, 0.012% Ti, 0.015% Nb, 0.001% B, and the balance is Fe and impurity elements.

[0029] A method for manufacturing a wear-resistant seamless steel pipe, comprising the following manufacturing steps:

[0030] S1. The above-mentioned smelting raw materials are sequentially processed by electric furnace smelting, LF refining, and RH degassing to produce molten steel that meets the composition requirements;

[0031] S2. Pouring molten steel into Φ250mm continuous casting slabs, sending the continuous casting slabs into the slow cooling pit for slow cooling for more than 32 hours, and exiting the pit;

[0032] S3. Send the continuous casting slab into the heating furnace at 800°C, heat it to 1250°C, keep it warm for 4 hours,...

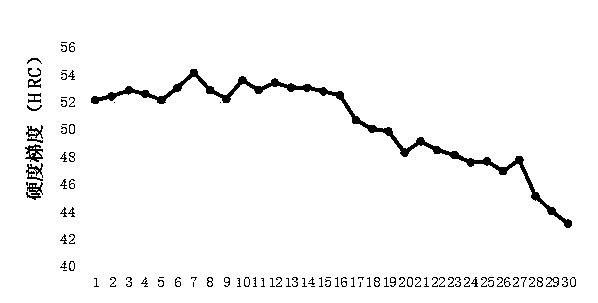

Embodiment 2

[0038] The specification of the seamless wear-resistant steel pipe in this example is 273×28mm, and the length is 15m. The chemical composition of the steel pipe is calculated by mass percentage: 0.36% C, 0.25% Si, 1.00% Mn, 0.01%P, 0.002%S , 0.50% Cr, 0.028% Al, 0.015% Ti, 0.02% Nb, 0.002% B, and the balance is Fe and impurity elements.

[0039] A method for manufacturing a wear-resistant seamless steel pipe, comprising the following manufacturing steps:

[0040] S1. The above-mentioned smelting raw materials are sequentially processed by electric furnace smelting, LF refining, and RH degassing to produce molten steel that meets the composition requirements;

[0041]S2. Pouring molten steel into Φ300mm continuous casting slab, sending the continuous casting slab into the slow cooling pit for slow cooling for more than 32 hours, and exiting the pit;

[0042] S3. Send the continuous casting slab into the heating furnace at 800°C, heat it to 1250°C, keep it warm for 5 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com