CH/Sb nano composite multi-layer phase-change film material, preparation method thereof and application thereof

A thin-film material and nano-composite technology, applied in the field of information storage, can solve the problems of low thermal conductivity and data retention, low thermal conductivity, etc., and achieve the effects of reducing thermal conductivity, good flexibility, and good phase change performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

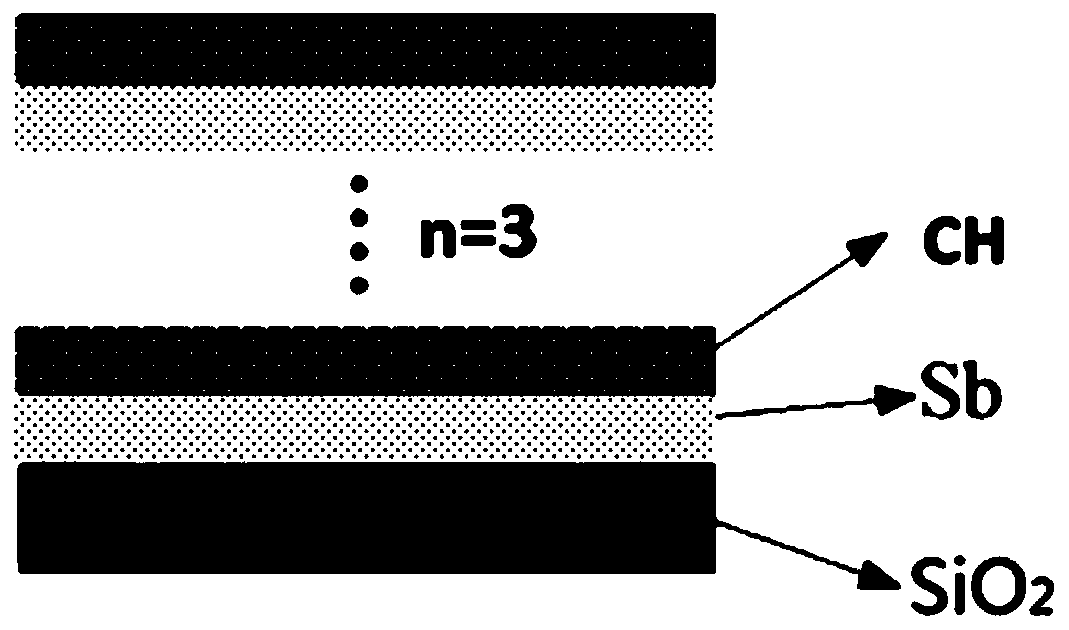

[0036] Embodiment 1: the prepared CH / Sb nanocomposite multilayer phase change film material (CH (1nm) / Sb (9nm)):

[0037] 1. Clean the silicon oxide substrate, clean the surface and back, remove dust particles, organic and inorganic impurities;

[0038] a) Strong ultrasonic cleaning in ethanol solution for 40-50 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0039] b) Dry the water vapor in an oven at 150°C until the surface of the silicon wafer is dry.

[0040] 2. Prepare CH / Sb thin films by AC sputtering (AC):

[0041] a) Install the CH and Sb sputtering targets, and vacuum the background to 1×10-4 Pa;

[0042] b) Set the sputtering power to 230W;

[0043] c) Using high-purity Ar gas as the sputtering gas (volume percentage up to 99.999%), setting the Ar gas flow rate to 30 sccm, and adjusting the sputtering gas pressure to 0.40 Pa.

[0044] d) Set the temperature of the substrate to be maintained at 180°C.

[0045] 3. Preparation...

Embodiment 2~7

[0052] Adjust the sputtering time of step b) and step c) in step 3 in embodiment 1 to obtain Sb film and CH film of different thicknesses, other operations and parameters are all the same as embodiment 1, and the sputtering time and compounding of each embodiment The thickness of the single-layer film material in the film is shown in Table 1:

[0053] Table 1

[0054]

Embodiment 8~10

[0070] Adjust the sputtering time of step b) and step c) in step 3 in embodiment 1 to obtain Sb film and CH film of different thicknesses, other operations and parameters are all the same as embodiment 1, and the sputtering time and compounding of each embodiment The thickness of the single-layer film material in the film is shown in Table 1:

[0071] Table 2

[0072]

[0073]

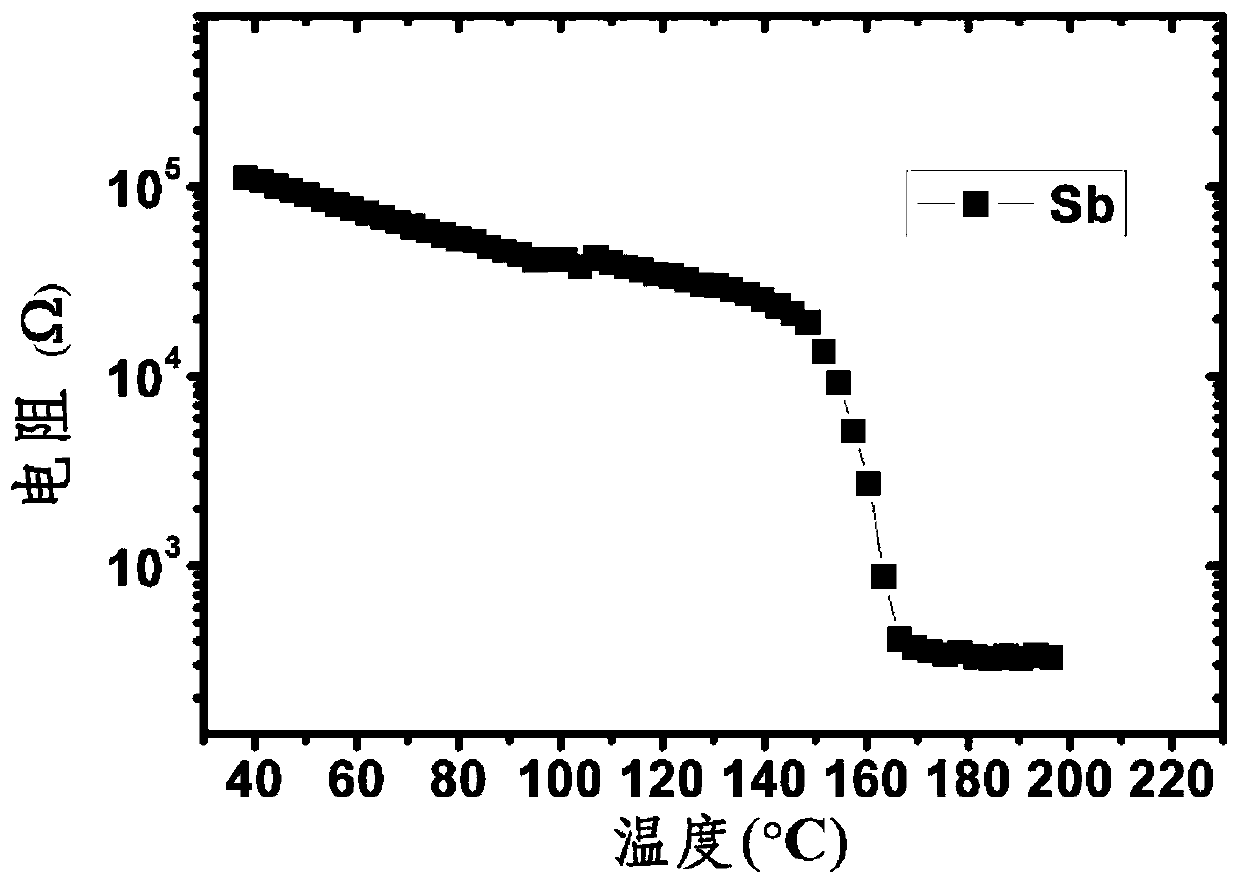

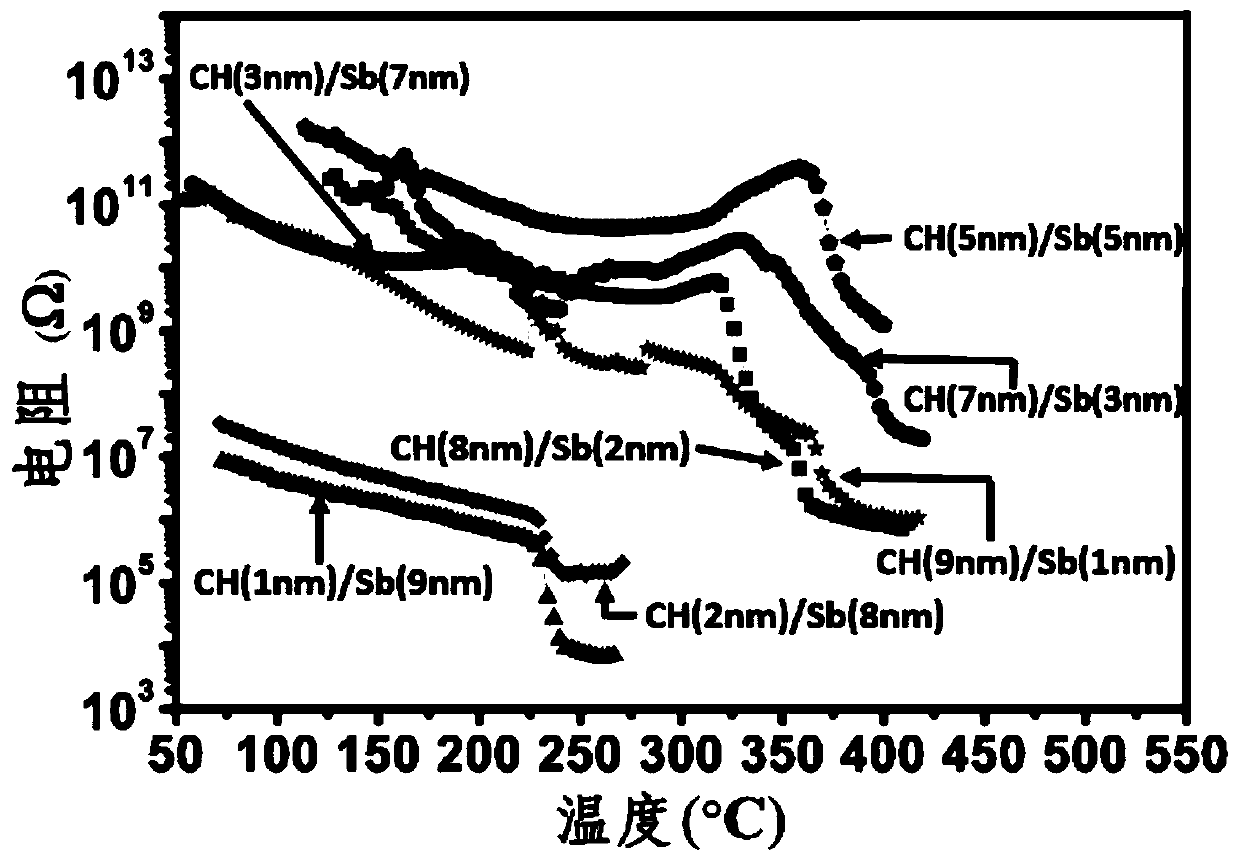

[0074] The CH / Sb nanocomposite multilayer phase change film material obtained in Example 1 and Examples 8 to 10 was tested, and the heating rate during the test was 20°C / min, and the CH / Sb nanocomposite multilayer phase change film material was obtained at The relationship between the in-situ resistance and temperature of Sb with a CH thickness of 1nm and different thicknesses is shown in Figure 4. It can be seen that as the thickness of the Sb composite layer increases, the phase transition temperature of the composite film also decreases. It shows that the overall phase change performance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com