PVDF-HFP/PMMA/CMC Composite Membrane and Its Preparation Method and Application

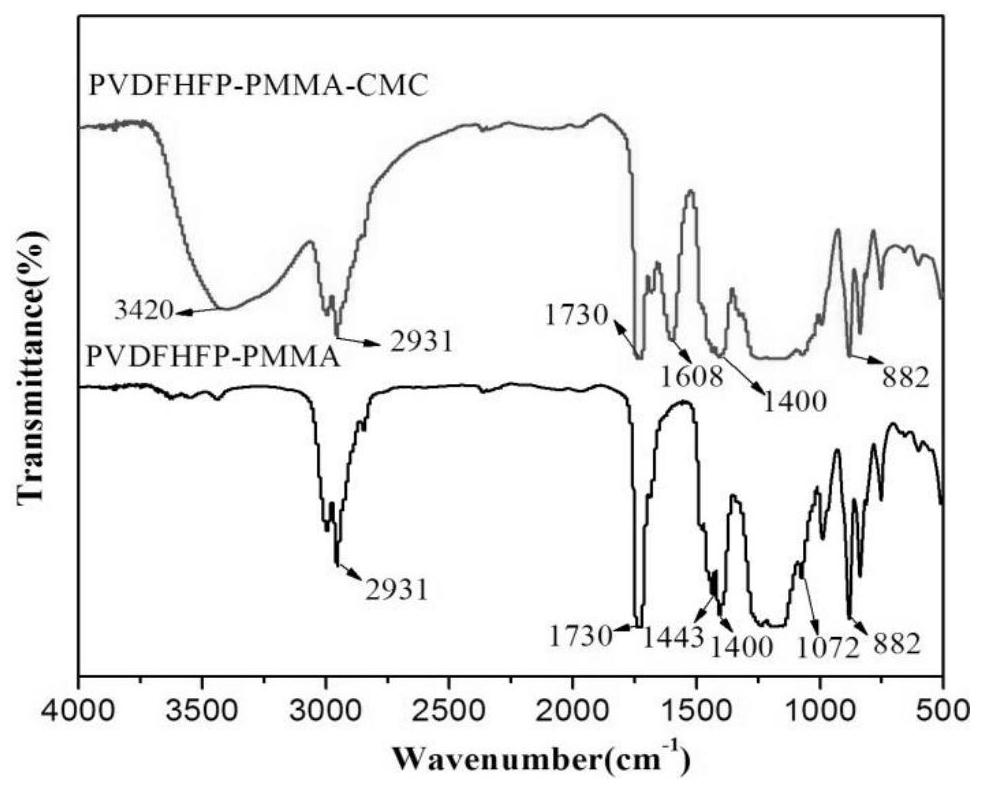

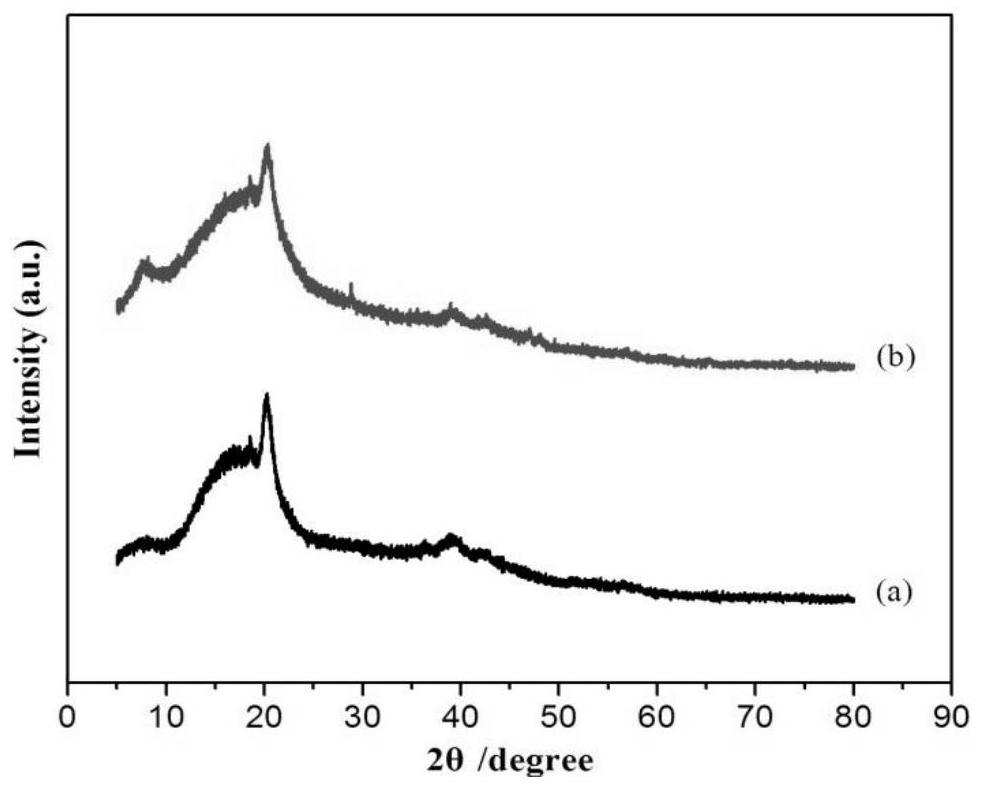

A technology of PVDF-HFP and composite membranes, which is applied in the field of PVDF-HFP/PMMA/CMC composite membranes and its preparation, can solve the problems of poor electrical conductivity of blended membranes, and achieve improved liquid retention, cycle life, and crystallinity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

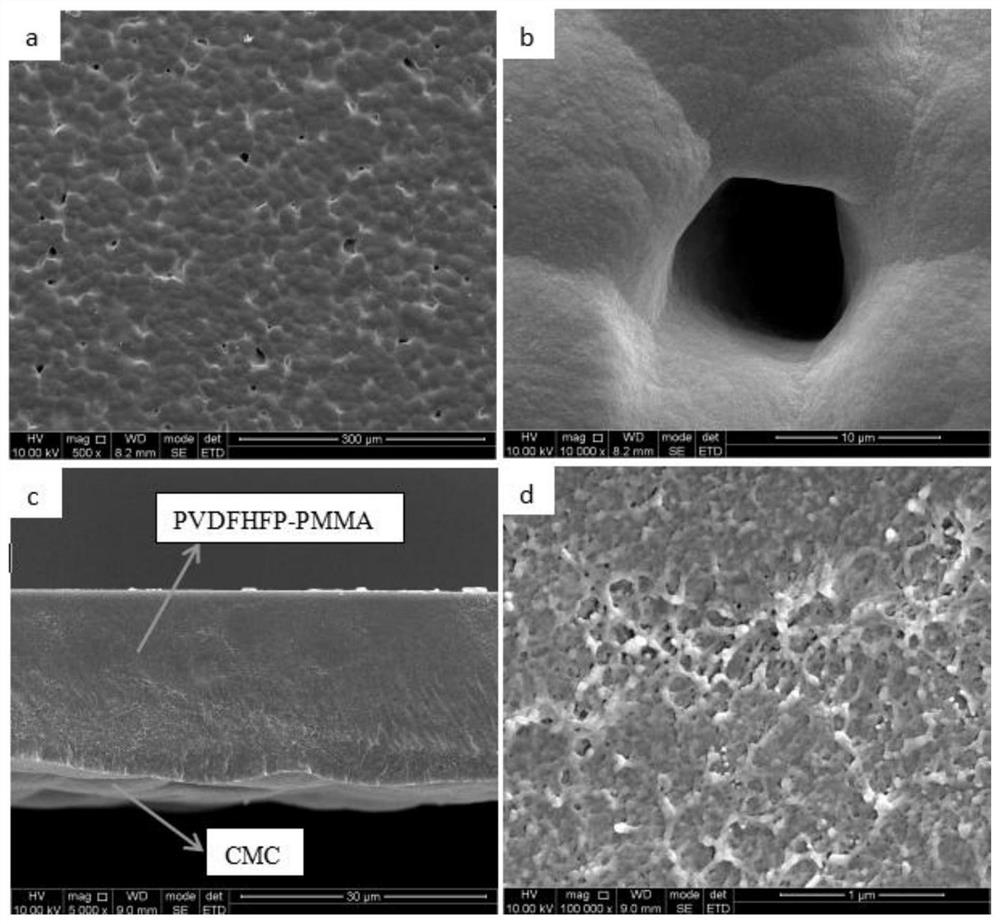

[0030] The present invention also provides a preparation method of the PVDF-HFP / PMMA / CMC composite membrane described in the above technical scheme, comprising the following steps:

[0031] (1) Provide PVDF-HFP / PMMA film;

[0032] (2) Apply a layer of CMC solution on the PVDF-HFP / PMMA film, and dry to obtain the PVDF-HFP / PMMA / CMC composite film.

[0033] The present invention provides PVDF-HFP / PMMA film earlier; The preparation method of described PVDF-HFP / PMMA film preferably comprises the following steps:

[0034] The PVDF-HFP, PMMA and solvent are mixed, and the PVDF-HFP / PMMA thin film is obtained through static defoaming, film formation and drying.

[0035] In the present invention, the solvent preferably includes acetone and DMF, and the volume ratio of the acetone and DMF is preferably 2.8-3.2:1, more preferably 3:1. The present invention does not specifically limit the amount of the solvent used, as long as the PVDF-HFP and PMMA can be fully mixed.

[0036] In the pr...

Embodiment 1

[0048] (1) Using acetone / DMF (volume ratio: 3:1) as solvent, add PVDF-HFP and PMMA particles (mass ratio: 1:1) into a single-necked flask, and stir at 60°C for 4 hours until the solution It is a transparent viscous liquid; stand to remove air bubbles, coat a film on a glass plate, and place it in a vacuum drying oven for 12 hours at 60°C to obtain a PVDF-HFP / PMMA film;

[0049] (2) Add 2g of carboxymethylcellulose (CMC), 50mL of water and 2.5mL of DMF into a single-necked flask, and stir at a constant temperature of 60°C for 4h until the solution becomes a transparent viscous liquid to obtain a CMC solution; stand to remove air bubbles , spread the PVDF-HFP / PMMA film on a glass plate, apply a layer of CMC solution on the PVDF-HFP / PMMA film with a spreader, and place it in a vacuum drying oven for 12 hours at 60°C for 50 seconds to obtain PVDF-HFP / PMMA / CMC composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com