A silver-doped modified manganese-based mullite oxidation catalyst and its preparation and application

An oxidation catalyst, mullite technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, heterogeneous catalyst chemical element, etc., can solve the problem of large particle size of nano Ag particles, Inability to give full play to the role of nano-Ag and other problems to achieve high NO conversion rate, favorable fast SCR reaction, and strong water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

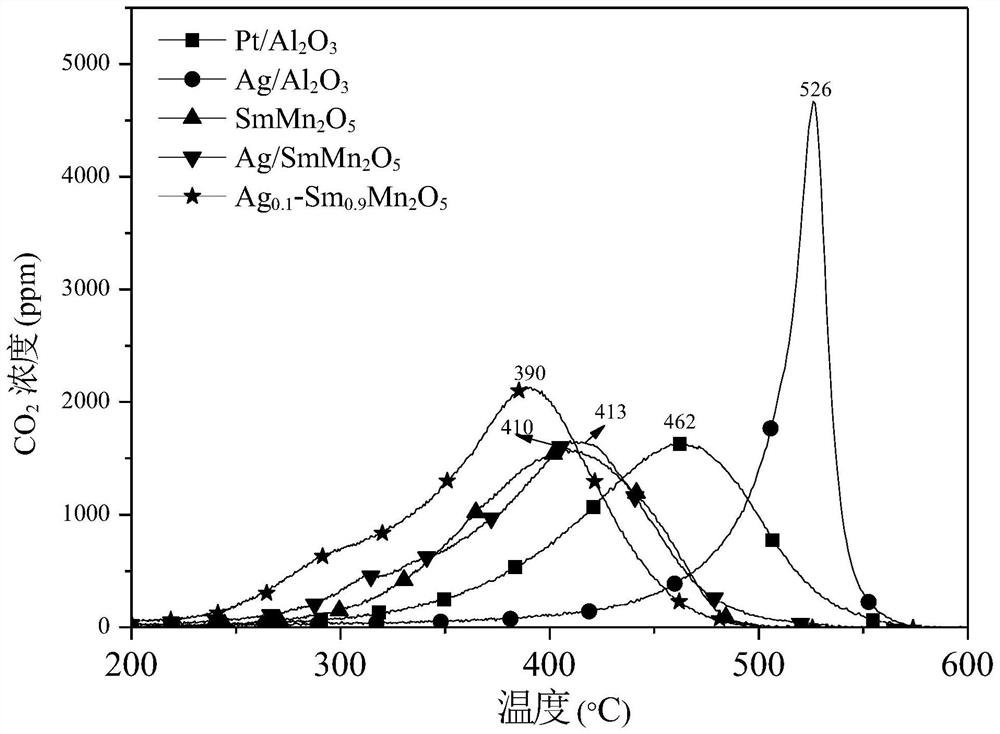

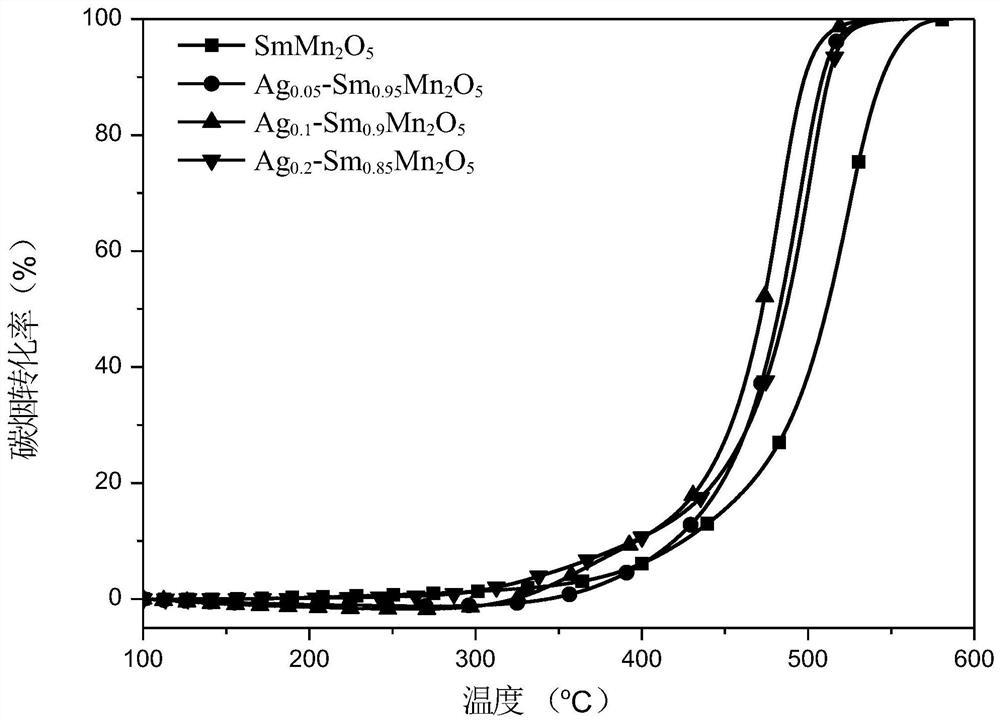

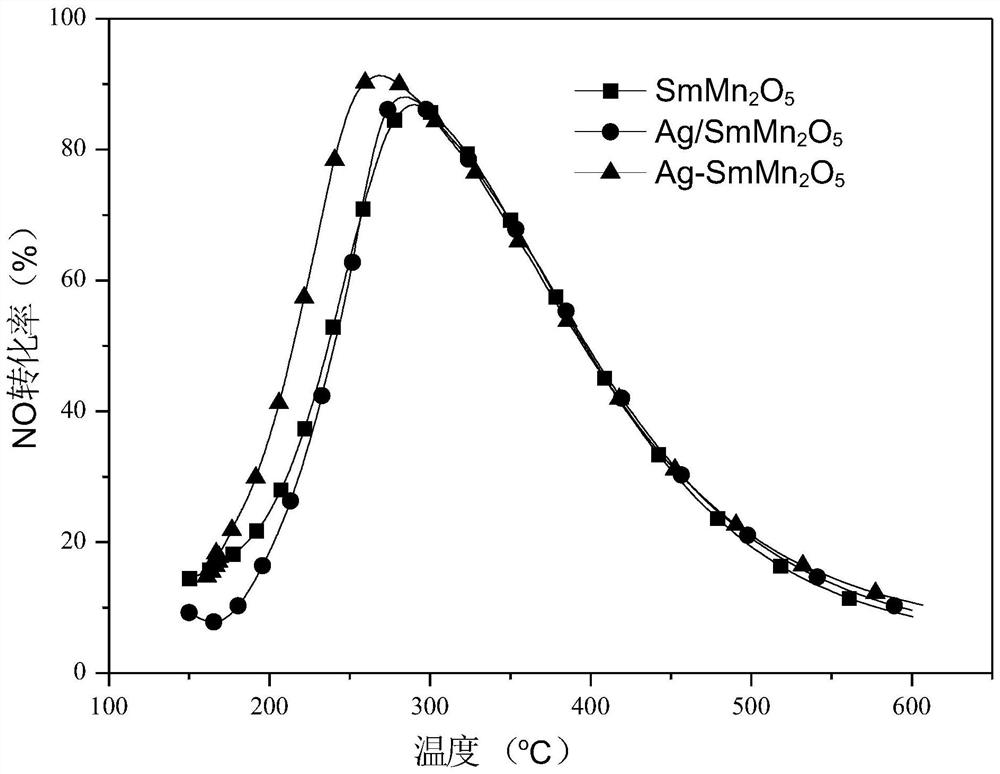

[0024] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.05 -Sm 0.95 mn 2 o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid to metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0025] The specific process is as follows: Weigh 0.7493g samarium nitrate, 0.01507g silver nitrate, 1.2703g manganese nitrate, dissolve in 100mL distilled water, 1.1252g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.05 -Sm 0.95 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

Embodiment 2

[0027] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.1 -Sm 0.9 mn 2o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid and metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0028] The specific process is as follows: Weigh 0.7144g samarium nitrate, 0.03034g silver nitrate, 1.2783g manganese nitrate, dissolve in 100mL distilled water, 1.1323g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.1 -Sm 0.9 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

Embodiment 3

[0030] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.2 -Sm 0.8 mn 2 o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid and metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0031] The specific process is as follows: Weigh 0.6431g samarium nitrate, 0.0615g silver nitrate, 1.2947g manganese nitrate, dissolve in 100mL distilled water, 1.1468g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.2 -Sm 0.8 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com