Preparation method of catalyst for selective catalytic reduction of NOx in oxygen-enriched environment

A catalyst and selective technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of high reaction temperature, low space velocity, low oxygen concentration, etc., to achieve high catalyst activity, preparation method Simple, simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

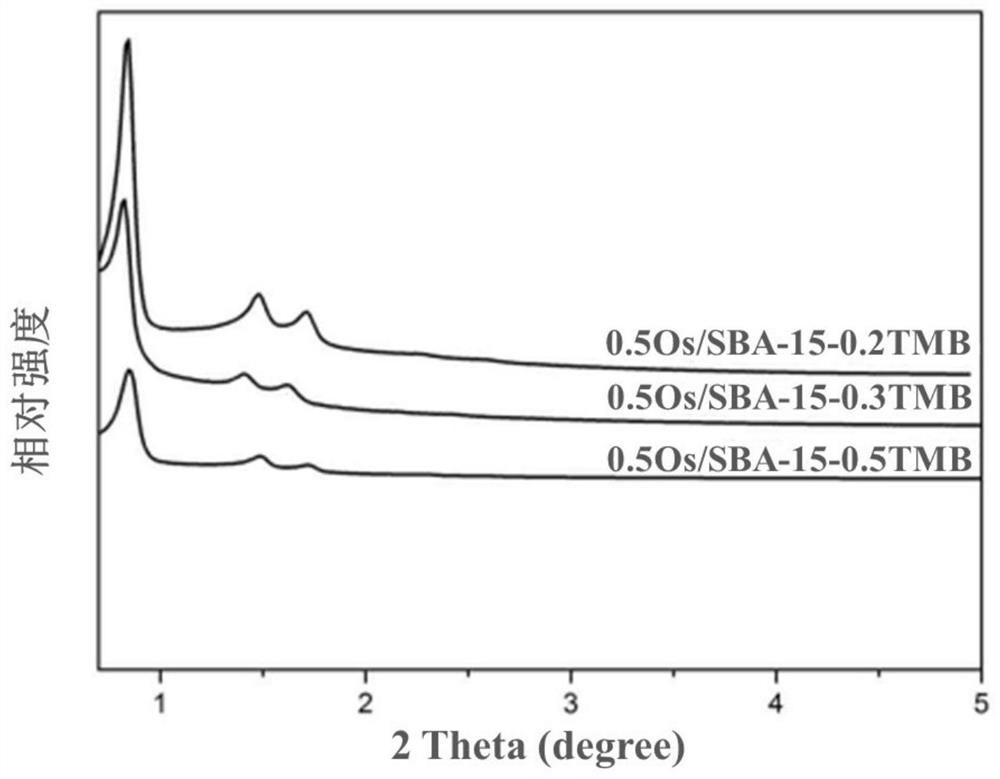

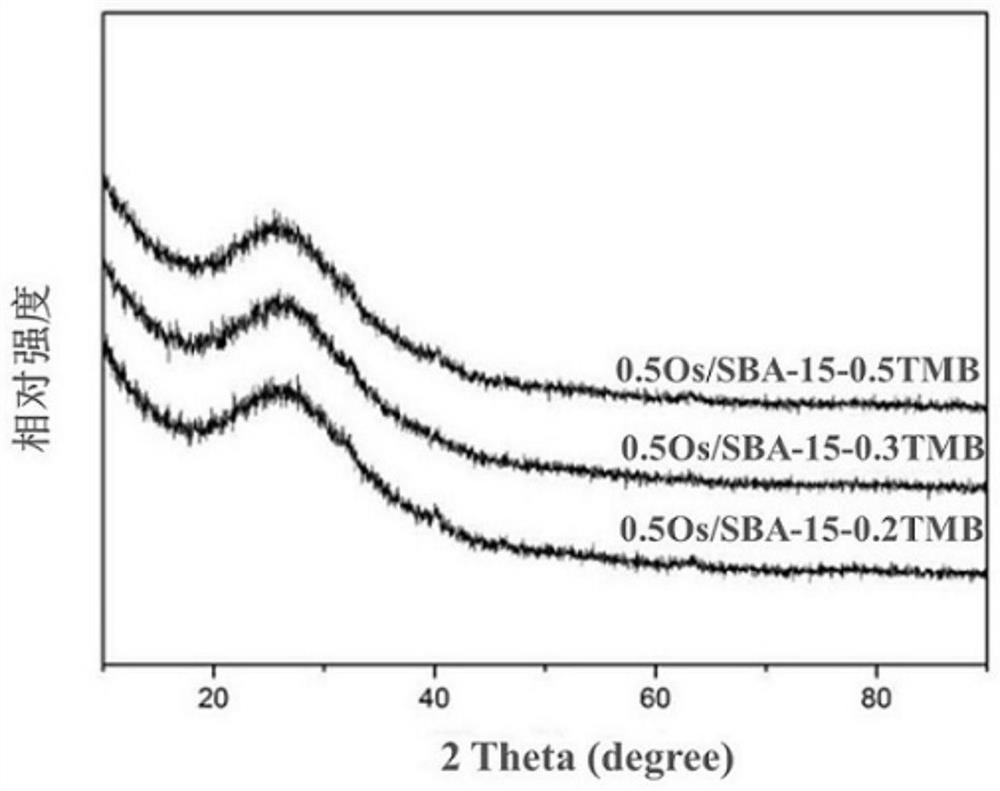

Embodiment 1

[0027] First weigh 2.0g of P123 in 75mL of hydrochloric acid solution (2mol / L), stir for 4 hours in a water bath at 40°C, wait until the template is completely dissolved, weigh 0.2g of 1,3,5-mesitylene and add it dropwise to the reaction solution , and then added dropwise 4.30g TEOS, and continued to stir for 24h. Transfer the obtained milky solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, and place it in a 100°C oven for crystallization for 24 hours, take it out and cool it to room temperature, filter and wash with a large amount of deionized water until it is neutral, and dry it at room temperature overnight. The obtained white solid sample was roasted at 550°C for 5 hours, and the obtained white block was properly ground to obtain the modified pure silicon molecular sieve SBA-15-0.2TMB.

[0028] According to the above pure silicon molecular sieve SBA-15-0.2TMB saturated water absorption rate (2.4mL / g), 0.0037g chloroosmic acid hydrate was...

Embodiment 2

[0031]First weigh 2.0g of P123 in 75mL of hydrochloric acid solution (2mol / L), stir for 4 hours in a water bath at 40°C, until the template is completely dissolved, weigh 0.3g of 1,3,5-mesitylene and add it to the reaction solution dropwise , and then added dropwise 4.30g TEOS, and continued to stir for 24h. Transfer the obtained milky solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, and place it in a 100°C oven for crystallization for 24 hours, take it out and cool it to room temperature, filter and wash with a large amount of deionized water until it is neutral, and dry it at room temperature overnight. The obtained white solid sample was roasted at 550°C for 5 hours, and the obtained white block was properly ground to obtain the modified pure silicon molecular sieve SBA-15-0.3TMB. The impregnation conditions of the active components are as in Example 1, and the catalyst 0.5Os / SBA-15-0.3TMB can be obtained, and the other reaction condition...

Embodiment 3

[0033] First weigh 2.0g of P123 in 75mL of hydrochloric acid solution (2mol / L), stir for 4 hours in a water bath at 40°C, and wait until the templating agent is completely dissolved, weigh 0.4g of 1,3,5-mesitylene and add it dropwise to the reaction solution , and then added dropwise 4.30g TEOS, and continued to stir for 24h. Transfer the obtained milky solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, and place it in a 100°C oven for crystallization for 24 hours, take it out and cool it to room temperature, filter and wash with a large amount of deionized water until it is neutral, and dry it at room temperature overnight. The obtained white solid sample was roasted at 550°C for 5 hours, and the obtained white block was properly ground to obtain the modified pure silicon molecular sieve SBA-15-0.4TMB. The impregnation conditions of the active components are as in Example 1, and the catalyst 0.5Os / SBA-15-0.5TMB can be obtained, and the other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com