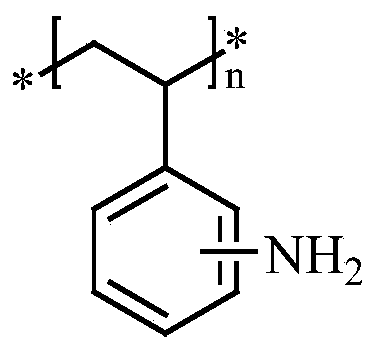

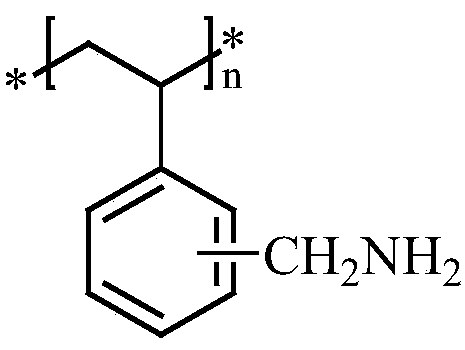

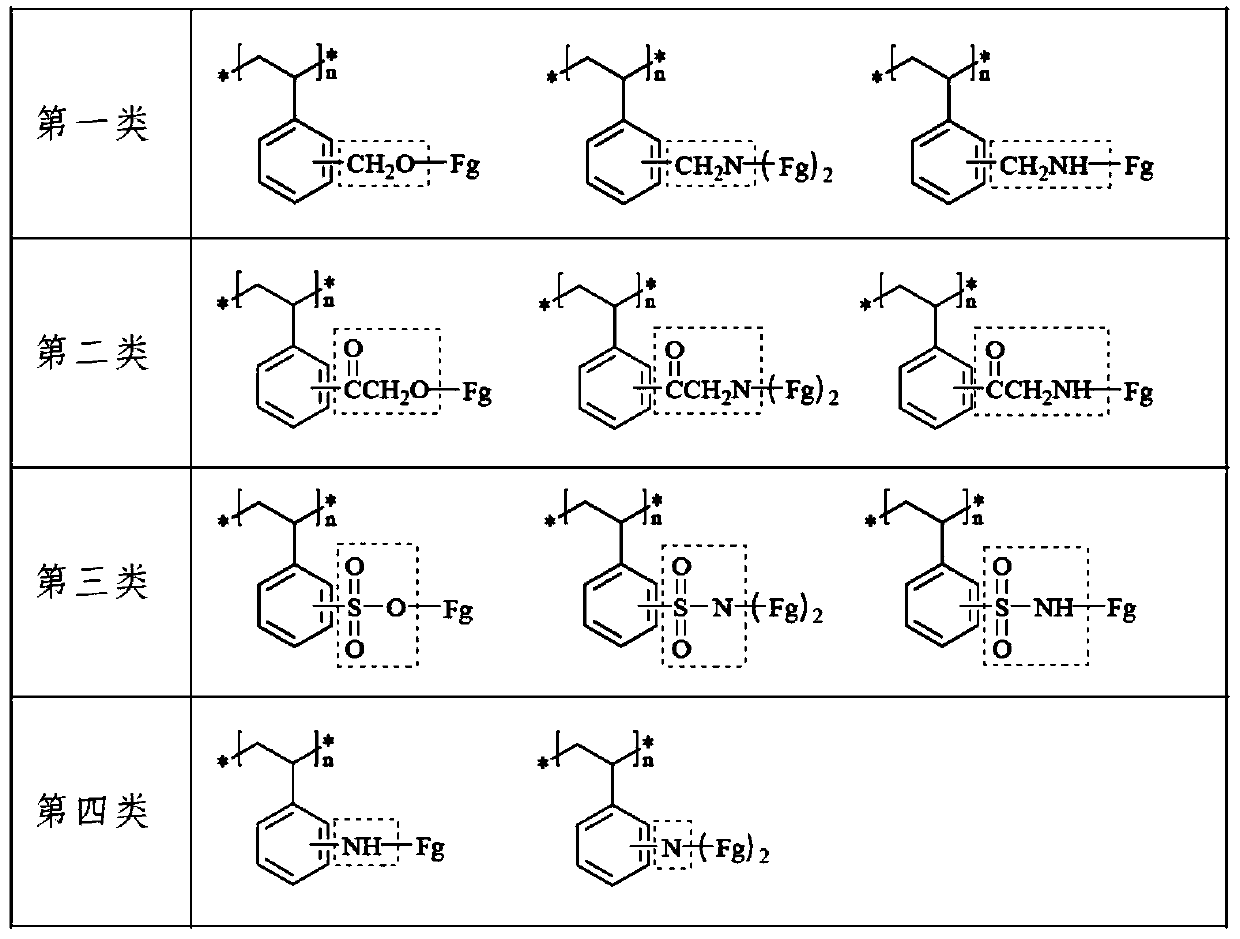

Novel functionalized polystyrene resin and preparation method thereof

A polystyrene resin and functionalization technology, applied in the field of functionalized polystyrene resin and its preparation, can solve the problems of reducing and increasing manufacturing costs, increasing the difficulty of material synthesis, etc., and achieve the effect of high activity of functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0044] Take 1g of dry PSD resin (cross-linking degree 4%, aldehyde content 4.4mmol / g) in 20ml DMSO to swell at room temperature for 24h, add functional reagent containing 2 times equivalent 1 Mix evenly with 20ml DMSO solution of 2 times the equivalent of potassium hydroxide, react at 60°C for 10h, filter the obtained resin, wash thoroughly with 95% ethanol, 1N aqueous sodium hydroxide solution, deionized water, 1N hydrochloric acid, deionized water successively, and vacuum dry , get the functional material PS- 1 , whose structure is as Figure 7 As shown, the functional group content is 2.7mmol / g.

specific Embodiment 2

[0046] Take 1g of dry PSD resin (cross-linking degree 7%, aldehyde group content 4.3mmol / g), add 15 times equivalent functionalization reagent 2 Mix evenly, heat at 80°C for 12 hours under the protection of nitrogen, wash the resin with 95% ethanol, 1N hydrochloric acid, deionized water, 1N sodium hydroxide aqueous solution and deionized water in sequence, and dry in vacuum to obtain the functional material PS- 2 , whose structure is as Figure 8 As shown, the functional group content is 3.9mmol / g.

specific Embodiment 3

[0048]Take 1g of dry PSD resin (cross-linking degree 7%, aldehyde content 4.3mmol / g), add 40mlDMSO to swell at room temperature for 15h, add 15 times equivalent functional reagent 2 Mix evenly, heat and react at 100°C for 10 hours, filter the obtained resin, wash it thoroughly with 95% ethanol, 1N hydrochloric acid, deionized water, 1N sodium hydroxide aqueous solution, and deionized water in sequence, and dry to obtain the functional material PS- 2 , whose structure is as Figure 8 As shown, the functional group content is 4.1mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com