Preparation method and application of zein-polysaccharide composite particle

A technology of polysaccharide compounding and prolamin, applied in the direction of food science, etc., can solve the problems of time-consuming and energy-consuming concentration process, difficult control of process parameters, etc., and achieve simple and easy-to-control preparation method, low processing cost, good thermal stability and The effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

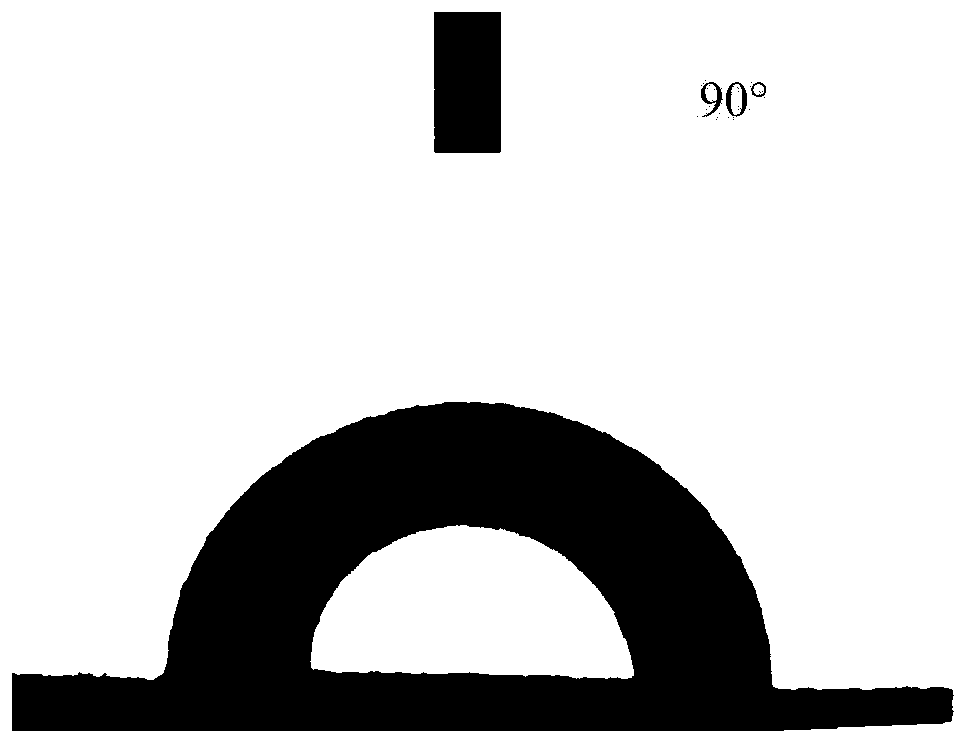

Image

Examples

Embodiment 1

[0028] Prepare gliadin-polysaccharide composite particles according to the following steps:

[0029] (1) Add 0.1 g of zein to 50 mL of ethanol aqueous solution (volume fraction of ethanol is 60%), stir at room temperature until fully dissolved, and obtain zein ethanol aqueous solution;

[0030] (2) Disperse 0.005g propylene glycol alginate (mass ratio of zein to propylene glycol alginate is 20:1) in 50mL ethanol aqueous solution (volume fraction of ethanol is 60%), and magnetically stir until completely dissolved to obtain Propylene glycol alginate ethanol aqueous solution;

[0031] (3) Add the zein ethanol solution obtained in step (1) to the propylene glycol alginate ethanol solution obtained in step (2) under stirring conditions, mix and stir for 2 hours to obtain a zein-propylene glycol alginate mixture ethanol aqueous solution;

[0032] (4) Preparation of composite particles by emulsification evaporation method: use a vacuum rotary evaporator at 45°C, 300r / min, and a pr...

Embodiment 2

[0036] Prepare gliadin-polysaccharide composite particles according to the following steps:

[0037] (1) Add 0.3 g of zein to 50 mL of ethanol aqueous solution (the volume fraction of ethanol is 70%), stir at room temperature until completely dispersed, and obtain an aqueous ethanol solution of zein;

[0038] (2) Add 0.03g propylene glycol alginate (mass ratio of zein to propylene glycol alginate is 10:1) into 50mL ethanol aqueous solution (volume fraction of ethanol is 70%), and magnetically stir until completely dissolved to obtain Propylene glycol alginate ethanol aqueous solution;

[0039] (3) Add the zein ethanol aqueous solution obtained in step (1) to the propylene glycol alginate ethanol aqueous solution obtained in step (2) under stirring conditions, mix and stir for 3 hours to obtain the zein-propylene glycol alginate mixture ethanol aqueous solution;

[0040](4) Prepare composite particles by emulsification evaporation method: use a vacuum rotary evaporator at 50°...

Embodiment 3

[0044] Prepare gliadin-polysaccharide composite particles according to the following steps:

[0045] (1) Add 0.5 g of zein to 50 mL of aqueous ethanol (the volume fraction of ethanol is 75%), stir at room temperature until completely dispersed, and obtain an aqueous ethanol solution of zein;

[0046] (2) Add 0.1g propylene glycol alginate (mass ratio of zein to propylene glycol alginate is 5:1) in 50mL ethanol aqueous solution (volume fraction of ethanol is 75%), and magnetically stir until completely dissolved to obtain Propylene glycol alginate ethanol aqueous solution;

[0047] (3) Add the zein ethanol solution obtained in step (1) to the propylene glycol alginate ethanol solution obtained in step (2) under stirring conditions, mix and stir for 3.5 hours to obtain zein-propylene glycol alginate Mixture ethanol aqueous solution;

[0048] (4) Prepare composite particles by emulsification evaporation method: use a vacuum rotary evaporator at 55°C, 600r / min, and a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com