Aluminum functionalized fluorescent carbon dot and preparation method and application thereof

A fluorescent carbon dot and functional technology, applied in the field of carbon dots, can solve the problems of long reaction time and unfavorable large-scale preparation, and achieve the effect of high-efficiency solid-state luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Specifically, the preparation method of the above aluminum-functionalized fluorescent carbon dots includes the following steps:

[0059] S1. Dissolving citric acid compound, urea, and aluminum salt in water, mixing them into a uniform colorless and transparent solution, and then placing it in a household microwave oven to heat and react;

[0060] S2. Grinding the solid product obtained from the reaction in S1 into powder with an agate mortar in a glove box and packaging it to obtain a solid green luminescent carbon dot phosphor;

[0061] The aluminum salt selected in step S1 is aluminum chloride hexahydrate to prevent the severe hydrolysis of aluminum chloride in water, and the citric acid is anhydrous citric acid or citric acid monohydrate.

[0062] The microwave oven used for the reaction in step S1 is a domestic microwave oven with a power of 650W, a reaction temperature of about 100-200°C, and a reaction time of -3min, until the solvent is completely evaporated to o...

Embodiment 1

[0068] The solid-state luminescent carbon-dot fluorescent powder is prepared by using citric acid, urea and aluminum chloride as raw materials through a one-step microwave heating method.

[0069] The preparation method of the above-mentioned solid-state luminescent carbon dot phosphor comprises the following steps:

[0070] S1. Dissolve 1.5g of citric acid monohydrate, 3g of urea and 2g of aluminum chloride hexahydrate in 10ml of ultrapure water to obtain a uniform colorless and transparent solution, then place it in a 650W household microwave oven, and heat it on medium heat for 3 minutes until all the liquid evaporates. Dry;

[0071] S2. Quickly transfer the solid product reacted in S1 to the glove box while hot, scrape the product out with a medicine spoon, and thoroughly grind the product into a fine powder with a mortar to obtain an aluminum-functionalized solid-state luminescent carbon dot phosphor.

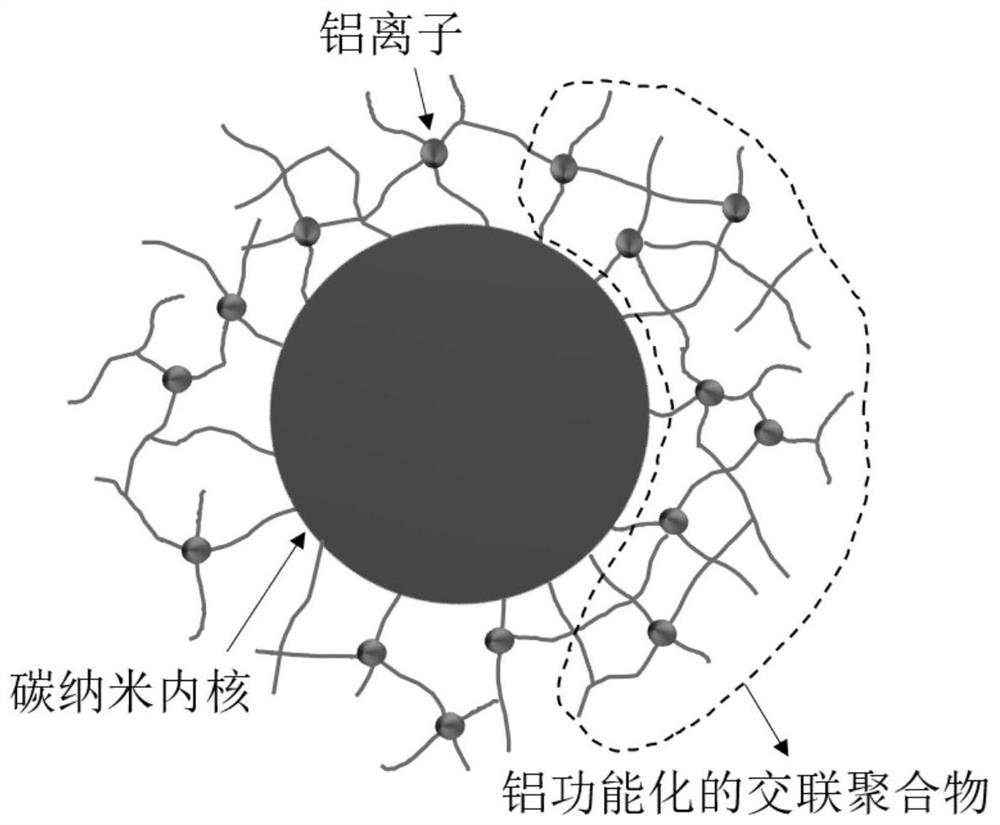

[0072] The schematic diagram of the structure of the above-mentioned...

Embodiment 2

[0079] The reaction conditions were the same as in Example 1, except that the amount of raw materials used was 1.5 g of citric acid monohydrate, 1 g of urea and 1 g of aluminum chloride hexahydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com