A conductive metal organic framework nanorod array composite material and its preparation and application

A nanorod array and organic framework technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory electrocatalytic performance, poor conductivity, difficult metal oxide compounding, etc., and achieve good selectivity, low detection limit, and excellent sensing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of copper-based organic framework nanocomposites Cu 2 O / CuHHTP / Cu 2 O NP, including the following steps:

[0031] (1) Use ethanol, 3mol / L hydrochloric acid and deionized water to ultrasonically clean the copper foam for 10 minutes;

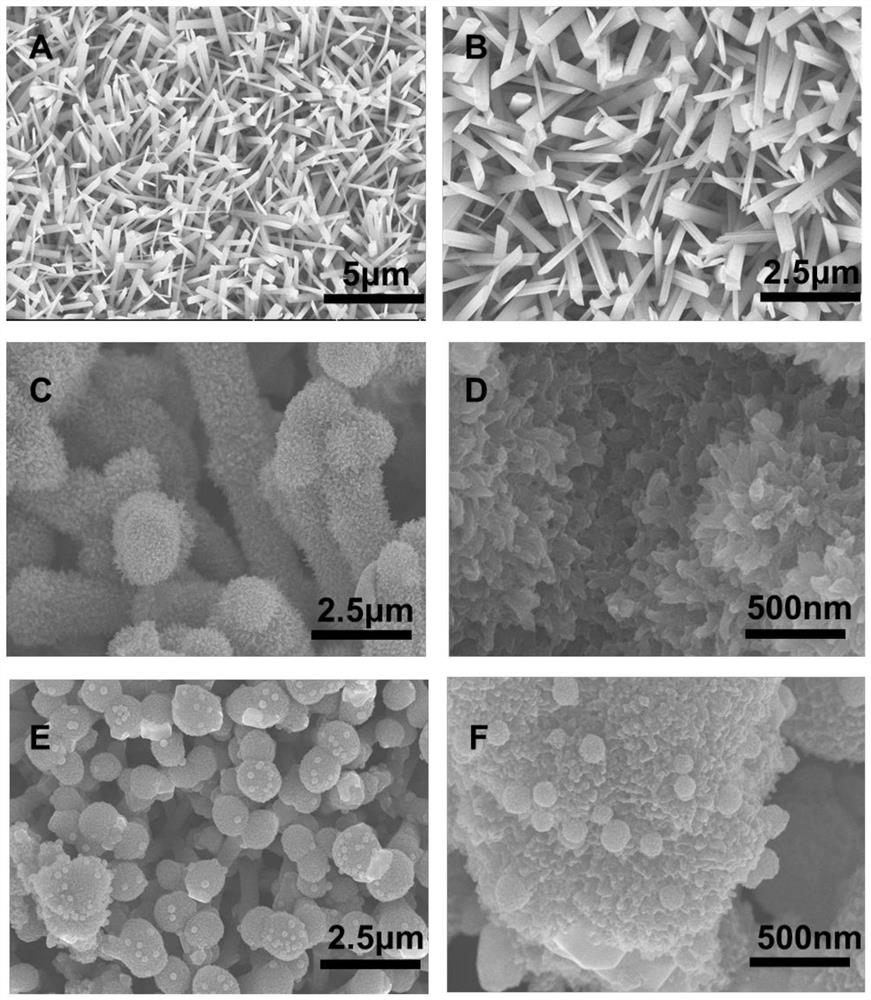

[0032] (2) the copper foam obtained in step (1) is placed in 2.5mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Cu(OH) supported by foamed copper was obtained by chemical oxidation in the mixed solution of 2 Nanorod arrays, such as figure 1 A in and figure 1 shown in B in;

[0033] (3) soak the foamed copper / copper hydroxide obtained in step (2) in the methanol solution of HHTP (the concentration of HHTP is 0.006mol / L) and heat water for 12h to generate Cu 2 O / CuHHTP core-shell nanorod arrays, such asfigure 1 C in and figure 1 as shown in D;

[0034] (4) the copper foam / Cu that generates in step (3) 2 Electroreduction of O / CuHHTP core-shell nanorod arrays with 0.1M PBS (ph=7.4) at -0.6V for 2h to obtain Cu 2 O particle em...

Embodiment 2

[0039] The difference between this example and Example 1 is that the conductive metal organic framework ligands used in step (3) are different, as described below.

[0040] (1) Use ethanol, 3mol / L hydrochloric acid and deionized water to ultrasonically clean the copper foam for 10 minutes;

[0041] (2) the copper foam obtained in step (1) is placed in 2.5mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Cu(OH) supported by foamed copper was obtained by chemical oxidation in the mixed solution of 2 nanorod arrays;

[0042] (3) soak the foamed copper / copper hydroxide obtained in step (2) in the methanol solution of HITP (the concentration of HITP is 0.006mol / L) and heat water for 12h to generate Cu 2 O / CuHITP core-shell nanorod arrays;

[0043] (4) the copper foam / Cu that generates in step (3) 2 Cu was obtained by electroreduction of O / CuHITP core-shell nanorod arrays and 0.1M PBS (ph=7.4) solution at -0.6V for 2h 2 O particle embedded Cu 2 O / CuHITP / Cu 2 O NP nanorod arrays. ...

Embodiment 3

[0045] This example differs from Example 1 in that the electroreduction voltage and electroreduction time of the electrochemical reduction are different, as described below.

[0046] (1) Use ethanol, 3mol / L hydrochloric acid and deionized water to ultrasonically clean the copper foam for 10 minutes;

[0047] (2) the copper foam obtained in step (1) is placed in 2.5mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Cu(OH) supported by foamed copper was obtained by chemical oxidation in the mixed solution of 2 nanorod arrays;

[0048] (3) Soak the foamed copper / copper hydroxide obtained in step (2) in the methanol solution of HHTP (the HHTP concentration is 0.006mol / L) and heat it for 3h to generate Cu 2 O / CuHHTP core-shell nanorod arrays;

[0049] (4) the copper foam / Cu that generates in step (3) 2 Electroreduction of O / CuHHTP core-shell nanorod arrays with 0.1M PBS (ph=7.4) at -0.8V for 1h to obtain Cu 2 O particle embedded Cu 2 O / CuHHTP / Cu 2 O NP nanorod arrays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com