Catalyst for catalytic combustion of methane and preparation method thereof

A methane catalytic combustion and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of non-precious metal catalyst activity and stability to be improved , to achieve the effect of maintaining catalytic performance, good dispersion and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

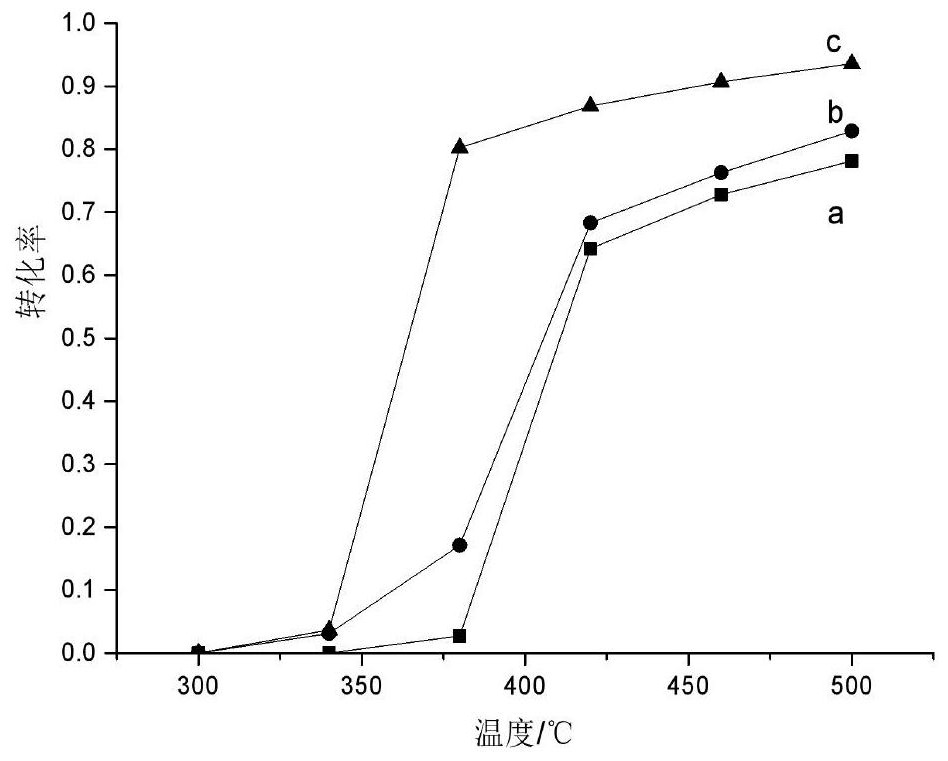

Image

Examples

Embodiment 1

[0024] Measure 400mL of cyclohexane, 120mL of 1-hexanol, and 100mL of NP-10 in a 1000mL beaker, turn on the mechanical stirring at 350r / min for 30min, prepare the microemulsion and divide it into two parts after stirring; weigh 3.4320g of zirconium nitrate , 3.4729g of cerium nitrate, dissolved in deionized water and diluted to 50mL, poured into a part of the emulsion, and continued to stir for 15 minutes to obtain a microemulsion; take 5mL of ammonia water and dilute to 50mL, add it to another part of the emulsion, and stir for 15 minutes; Mix two parts of emulsion, keep stirring at a speed of 350r / min for 1 hour, and then let it stand for 3 hours; put the standing emulsion in a water bath at 60°C, stir vigorously at 400r / min for 30 minutes; take it out, cool and age overnight; add After stirring with 200mL ethanol for 30min, filter directly with suction, wash with deionized water several times during this period, and finally wash with ethanol; put the filter cake in a vacuum ...

Embodiment 2

[0026] The difference between this example and Example 1 is that in this example, the active component impregnating solution is first added to the mixed nitrate aqueous solution, and then the two emulsions are mixed, and the carrier is prepared by a one-step microemulsion method.

[0027] Measure 400mL of cyclohexane, 120mL of 1-hexanol, and 100mL of NP-10 in a 1000mL beaker, turn on the mechanical stirring at 350r / min for 30min, prepare the microemulsion and divide it into two parts after stirring; weigh 6.8702g of zirconium nitrate Dissolve 1.1668g of cobalt nitrate in deionized water and dilute to 50mL, pour into one emulsion and continue to stir for 15min; take 5.90mL of ammonia water and dilute to 50mL, pour it into another emulsion, and stir for 15min; mix the two emulsions , keep stirring at a speed of 350r / min for 1 hour, then let it stand for 3 hours; put the emulsion after standing in a water bath at 60°C, stir vigorously at 400r / min for 30 minutes; take it out, cool ...

Embodiment 3

[0029] Measure 400mL cyclohexane, 120mL 1-hexanol, and 100mL NP-10 in a 1000mL beaker, turn on mechanical stirring at 350r / min for 30min, and divide into two parts after stirring; weigh 3.4344g of zirconium nitrate, cerium nitrate 3.4720g, 1.1640g of cobalt nitrate was dissolved in deionized water and diluted to 50mL, poured into a prepared emulsion, and continued to stir for 15min; took 6.24mL of ammonia water and diluted to 50mL, poured it into another emulsion, stirred 15min; the two emulsions were mixed and continued to react for 1 hour, and then stood still for 3 hours; put the standing emulsion in a water bath at 60°C, and vigorously stirred at 400r / min for 30 minutes; took it out, cooled it and aged it overnight; sucked out the supernatant, added After stirring with 200mL ethanol for 30min, filter directly with suction, wash with deionized water several times during this period, and finally wash with ethanol; put the filter cake in a vacuum oven at 40°C for drying, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com