CaTiO3@ZnIn2S4 nano composite material as well as preparation method and application thereof

A nanocomposite material, znin2s4 technology, applied in the field of photocatalysis, can solve the problems of reduced solar energy utilization, low visible light absorption, large forbidden band width, etc., to achieve the effects of easy purchase, abundant resources, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Place 0.25mmol calcium nitrate in a beaker, add 5mL deionized water and stir for 10min to form a uniform solution, then add 0.84mmol tetrabutyl titanate and 0.84mmol polyethylene glycol-200 to the solution, stir 30min, then add 1.68×10 to the resulting solution -4 mmol sodium hydroxide aqueous solution, stir evenly, transfer the solution to a 50mL stainless steel reactor with PTFE lining, and react at 200℃ for 17h; after the natural cooling, the reaction solution is centrifuged, washed, dried, and collected , Get hollow CaTiO 3 cuboid;

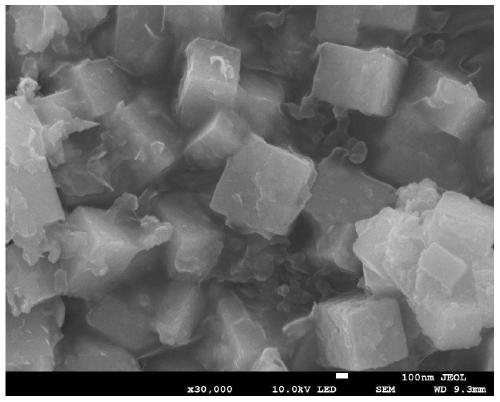

[0028] (2) Take 10.5mg of the hollow CaTiO obtained in step (1) 3 The cuboid was moved into an oil bath, and 37.8 mg of zinc chloride, 61.95 mg of indium chloride, and 42 mg of thioacetamide were added. The temperature was raised to 80°C at a rate of 2°C / min in an air atmosphere, and the oil bath was stirred for 3 hours to obtain CaTiO 3 @ZnIn 2 S 4 Nanocomposite materials.

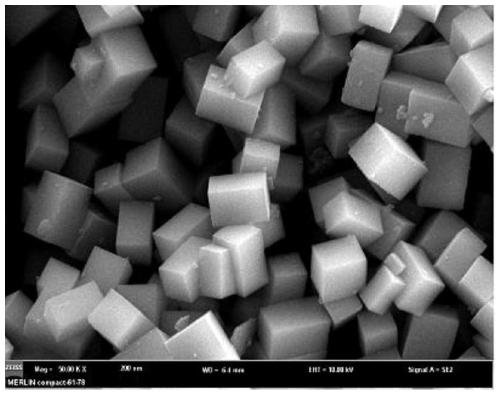

[0029] For the hollow CaTiO prepared in step (1) 3 Cuboid for...

Embodiment 2

[0032] In CaTiO 3 @ZnIn 2 S 4 Do not add hollow CaTiO during the preparation of nanocomposites 3 Cuboid, the rest of the reagent dosage and operation steps are the same as step 2 of Example 1.

Embodiment 3

[0034] In CaTiO 3 @ZnIn 2 S 4 No ZnIn is added during the preparation of nanocomposites 2 S 4 , The rest of the reagent dosage and operation steps are the same as step 1 in Example 1.

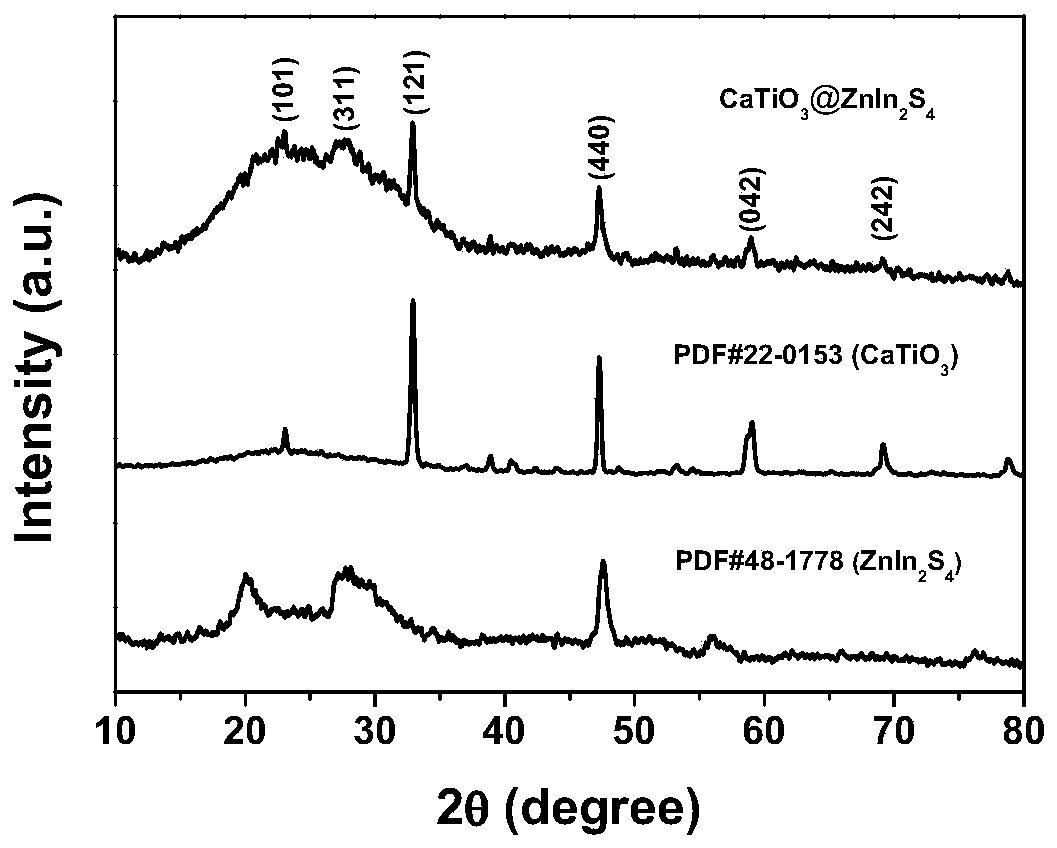

[0035] XRD tests were performed on the products obtained in Examples 1, 2 and 3, and the test results are shown in image 3 . As shown, the CaTiO 3 @ZnIn 2 S 4 Comparing the X-ray diffraction peak of the nanocomposite with the X-ray diffraction peak of a single material, it can be seen that CaTiO 3 With ZnIn 2 S 4 Successful recombination, the diffraction peaks are matched with the corresponding crystal planes and no impurity peaks.

[0036] The specific analysis is as follows: the strong diffraction peaks at 2θ=23.1°, 32.9°, 59.0° and 69.5° are similar to those of perovskite CaTiO 3 The (101), (121), (042) and (242) crystal planes (PDF#22-0153) match. The strong diffraction peaks at 27.8° and 48.4° are the same as ZnIn 2 S 4 The (311) and (440) crystal planes (PDF#48-1778) match. According to thes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com